IBC (Intermediate Bulk Container) are containers used for the transportation and storage of liquid materials. It usually consists of a plastic tank in the shape of a rectangular prism, a metal cage surrounding it, and a pallet suitable for forklift transport. Being cheap and

easy to find, easy to transport, stack and reuse has made it widely used all over the world, especially for chemical products.

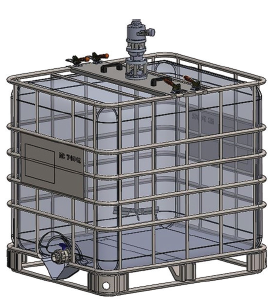

[caption id="attachment_130631" align="aligncenter" width="249"]

Figure 1.1 – Metal Pallet IBC Tank[/caption]

Generally, products stored in IBCs need to be mixed and homogenized due to sedimentation or decomposition problems. The fact that IBCs have a narrow orifice and a high volume of 1m3 makes mixing a little difficult. In order for the mixer propeller to pass

through a narrow orifice such as 15 cm, but to mix liquids in such a high volume effectively, it must be in a foldable structure.

Electric motor mixers which are often used to mix IBCs, are generally powerful enough and can provide effective mixing, but they also have some disadvantages.

First of all, they can only be transported with the forklift or crane system because they are too heavy for a person to lift and place on the IBC alone due to the electric motor. A mixer with an electric, pneumatic or hydraulic self-lowering structure cannot be used mobile.

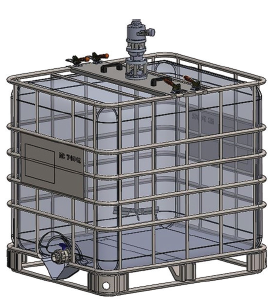

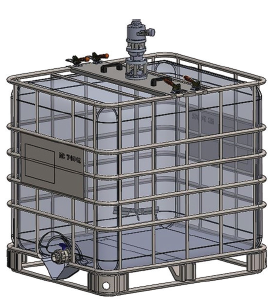

[caption id="attachment_130632" align="aligncenter" width="468"]

Figure 1.2 – Metal Pallet IBC Tank[/caption]

In order to make variable speed adjustment in an electric mixer, a frequency inverter must also be required, as well as an electrical connection to feed the motor, equipment such as buttons, fuses, and switches. These also severely limit the mobility of the electric mixer.

With the use of special type IBCs with anti-static structure and grounding, flammable-inflammable chemicals have started to be transported frequently in IBCs. For this reason, IBC mixers are also required to be ex-proof. However, electric motors and switchgears with ex-proof features are both larger and heavier and their costs increased considerably.

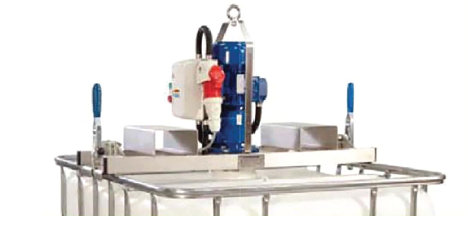

[caption id="attachment_130634" align="aligncenter" width="274"]

Figure 1.3 – ADA Mix Pneumatic

IBC Mixer[/caption]

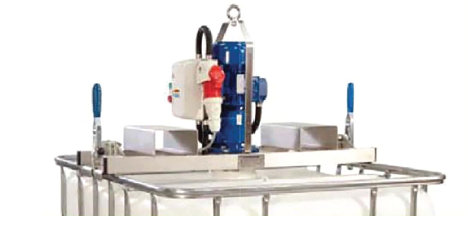

[caption id="attachment_130635" align="aligncenter" width="507"]

Figure 1.4 –ADA Mix Pneumatic IBC Mixer[/caption]

Due to these disadvantages, the most suitable solution for mobile mixing of IBCs has been air motor IBC mixers working with compressed air. As Kairos Makina, we designed ADA MIX IBC mixers to meet this need.

The 1.25kW ex-proof air motor is both powerful and quite small and light compared to an

electric motor. The fact that only one compressed air hose can be connected and used and that the mixing speed can be adjusted easily with the air valve on it provides great convenience.

Effective mixing of liquids of different viscosities and densities can be provided with different types of foldable propellers and reducer options in different ratios.

The impeller, shaft and mixer body made of stainless steel both give the product a solid structure and ensure its longevity against various chemicals.

With the locking mechanisms on the body, the mixer can be easily fixed to the metal IBC cage and can be used safely.

The lightweight construction of the ADA MIX IBC mixers allows it to be placed and removed on the IBC without using any additional equipment. In this way, IBCs can now be mixed easily wherever the air hose can reach.

Cevdet Kaplan

R&D and Production Manager

Kairos Machinery

Figure 1.1 – Metal Pallet IBC Tank[/caption]

Generally, products stored in IBCs need to be mixed and homogenized due to sedimentation or decomposition problems. The fact that IBCs have a narrow orifice and a high volume of 1m3 makes mixing a little difficult. In order for the mixer propeller to pass

through a narrow orifice such as 15 cm, but to mix liquids in such a high volume effectively, it must be in a foldable structure.

Electric motor mixers which are often used to mix IBCs, are generally powerful enough and can provide effective mixing, but they also have some disadvantages.

First of all, they can only be transported with the forklift or crane system because they are too heavy for a person to lift and place on the IBC alone due to the electric motor. A mixer with an electric, pneumatic or hydraulic self-lowering structure cannot be used mobile.

[caption id="attachment_130632" align="aligncenter" width="468"]

Figure 1.1 – Metal Pallet IBC Tank[/caption]

Generally, products stored in IBCs need to be mixed and homogenized due to sedimentation or decomposition problems. The fact that IBCs have a narrow orifice and a high volume of 1m3 makes mixing a little difficult. In order for the mixer propeller to pass

through a narrow orifice such as 15 cm, but to mix liquids in such a high volume effectively, it must be in a foldable structure.

Electric motor mixers which are often used to mix IBCs, are generally powerful enough and can provide effective mixing, but they also have some disadvantages.

First of all, they can only be transported with the forklift or crane system because they are too heavy for a person to lift and place on the IBC alone due to the electric motor. A mixer with an electric, pneumatic or hydraulic self-lowering structure cannot be used mobile.

[caption id="attachment_130632" align="aligncenter" width="468"] Figure 1.2 – Metal Pallet IBC Tank[/caption]

In order to make variable speed adjustment in an electric mixer, a frequency inverter must also be required, as well as an electrical connection to feed the motor, equipment such as buttons, fuses, and switches. These also severely limit the mobility of the electric mixer.

With the use of special type IBCs with anti-static structure and grounding, flammable-inflammable chemicals have started to be transported frequently in IBCs. For this reason, IBC mixers are also required to be ex-proof. However, electric motors and switchgears with ex-proof features are both larger and heavier and their costs increased considerably.

[caption id="attachment_130634" align="aligncenter" width="274"]

Figure 1.2 – Metal Pallet IBC Tank[/caption]

In order to make variable speed adjustment in an electric mixer, a frequency inverter must also be required, as well as an electrical connection to feed the motor, equipment such as buttons, fuses, and switches. These also severely limit the mobility of the electric mixer.

With the use of special type IBCs with anti-static structure and grounding, flammable-inflammable chemicals have started to be transported frequently in IBCs. For this reason, IBC mixers are also required to be ex-proof. However, electric motors and switchgears with ex-proof features are both larger and heavier and their costs increased considerably.

[caption id="attachment_130634" align="aligncenter" width="274"] Figure 1.3 – ADA Mix Pneumatic

Figure 1.3 – ADA Mix Pneumatic Figure 1.4 –ADA Mix Pneumatic IBC Mixer[/caption]

Due to these disadvantages, the most suitable solution for mobile mixing of IBCs has been air motor IBC mixers working with compressed air. As Kairos Makina, we designed ADA MIX IBC mixers to meet this need.

The 1.25kW ex-proof air motor is both powerful and quite small and light compared to an

electric motor. The fact that only one compressed air hose can be connected and used and that the mixing speed can be adjusted easily with the air valve on it provides great convenience.

Effective mixing of liquids of different viscosities and densities can be provided with different types of foldable propellers and reducer options in different ratios.

The impeller, shaft and mixer body made of stainless steel both give the product a solid structure and ensure its longevity against various chemicals.

With the locking mechanisms on the body, the mixer can be easily fixed to the metal IBC cage and can be used safely.

The lightweight construction of the ADA MIX IBC mixers allows it to be placed and removed on the IBC without using any additional equipment. In this way, IBCs can now be mixed easily wherever the air hose can reach.

Figure 1.4 –ADA Mix Pneumatic IBC Mixer[/caption]

Due to these disadvantages, the most suitable solution for mobile mixing of IBCs has been air motor IBC mixers working with compressed air. As Kairos Makina, we designed ADA MIX IBC mixers to meet this need.

The 1.25kW ex-proof air motor is both powerful and quite small and light compared to an

electric motor. The fact that only one compressed air hose can be connected and used and that the mixing speed can be adjusted easily with the air valve on it provides great convenience.

Effective mixing of liquids of different viscosities and densities can be provided with different types of foldable propellers and reducer options in different ratios.

The impeller, shaft and mixer body made of stainless steel both give the product a solid structure and ensure its longevity against various chemicals.

With the locking mechanisms on the body, the mixer can be easily fixed to the metal IBC cage and can be used safely.

The lightweight construction of the ADA MIX IBC mixers allows it to be placed and removed on the IBC without using any additional equipment. In this way, IBCs can now be mixed easily wherever the air hose can reach.