Author: Dr. Şahin Öztürk

PUD Technical Sales & Business Development Manager

İnterplast Kimya

1. Introduction

Adhesives used in footwear manufacturing do not merely serve to bond two materials together; they directly impact the product’s durability, flexibility, and visual integrity. Although solvent-based adhesive systems, which have been widely used for years, offer important advantages such as strong adhesion and rapid drying, they are increasingly becoming restrictive in both environmental and operational aspects due to their high VOC (volatile organic compound) content, flammability risks, and toxic vapor emissions.

In recent years, both environmental regulations (REACH, CLP, TS EN ISO 16000) and expectations for sustainable production have driven the need for a transformation in adhesive systems. One of the prominent alternatives in this transformation is systems based on water-based polyurethane dispersions (PUDs) (1–3).

PUD systems have become a serious alternative—and for many manufacturers, a new standard—to solvent-based systems, thanks to their low VOC profile, high surface compatibility, formulation flexibility, and suitability for multi-layer footwear production processes. Especially in manual and vacuum press applications, they are preferred for offering a balance between low activation temperature and long open time. In line with this change, many major manufacturers in Europe and North America, as well as an increasing number in Turkey, are gradually restructuring their production lines for PUD systems. There is also a noticeable increase in the demand for products that comply with local regulations and international certification programs (OEKO-TEX®, Blue Angel, GREENGUARD®).

As Interplast Kimya, we develop PUD systems specifically formulated for application, focusing on the technical requirements of the footwear industry during this transformation process. This article addresses the chemical structure, application conditions, performance criteria, and future potential directions of PUD systems within a technical framework.

2. Structure of Polyurethane Dispersions

PUD systems, which form the basis of water-based adhesives used in the footwear sector, are obtained by reacting isocyanate-terminated prepolymers with chain extenders in an aqueous medium. The polyols (polyether, polyester, PCL), diisocyanates (IPDI, HDI), chain extenders (BDO), and neutralizing agents (DMEA, TEA) used in PUD system design determine the mechanical, thermal, and rheological structure of the final product.

After dispersing the prepolymer into the water phase, the film that remains once the water evaporates forms a flexible, adhesive, moisture- and heat-resistant structure. PUD films, which are inherently hydrophobic and insoluble in water, exhibit excellent adhesion to many surfaces, including glass and polymeric fibers. Today, PUD technology not only presents a strong alternative to solvent-based adhesives but also offers more functional adhesive systems through bio-based content, crosslinker compatibility, and multilayer applications. Advanced PUD systems incorporate more complex structures such as multiblock copolymers, internally crosslinked segments, and hybrid structures (PU-acrylic, PU-silicone) (4).

3. Application Conditions and Formulation Strategies

3.1. Film Formation, Drying Dynamics, and Energy Efficiency

The drying rate and film formation of adhesives in footwear production lines are critical factors that directly affect the efficiency of the lines. Especially in manual applications, vacuum presses, and low-temperature oven systems, controlled and rapid film formation reduces energy consumption and shortens production time, thereby increasing process stability.

In PUD systems, film formation is achieved as dispersion particles coalesce upon water evaporation. In this process, polymer structure-dependent parameters such as minimum film formation temperature (MFFT) and glass transition temperature (Tg) play a decisive role. Low Tg segments allow for film formation at lower temperatures, enhancing energy efficiency. However, this does not directly affect the drying rate, but rather improves the minimum temperature required for film formation.

PUD systems with polycaprolactone segments enhance film durability not only through their flexibility but also through their ability to crystallize. These PUDs provide flexible and cohesive film formation even at low temperatures, making them competitive with solvent-based systems.

Key control points to consider in formulation strategy include:

• Drying time: < 10 minutes (applicable at room temperature)

• Film thickness: 40–80 µm (optimal range for final bond strength)

• Application environment: <5% relative humidity, 20–30 °C recommended

• MFFT value: 5–15 °C range enables film formation even at low temperatures

Systems formulated with these parameters offer high adhesion performance and surface quality even in low-temperature lines, providing viable alternatives to solvent-based systems.

3.2. Surface Compatibility, Surface Energy, and Adhesion Mechanisms

Surfaces like PVC, TPU, and EVA have low surface energy, making it difficult to form strong bonds directly with PUD systems. Therefore:

• Surface pretreatment (sanding, corona, flame)

• Preparing the surface with primer systems

• Testing the compatibility of PUD systems with other water-based contact primers is essential.

Additionally, adhesion promoters added to the formulation enhance the chemical interaction between the particles and substrate, increasing adhesion stability. The balance between the surface energy of the substrate and the surface tension of the adhesive is critical for spreadability and bond integrity.

3.3. Open Time and Activation

In PUD systems, open time and activation conditions directly affect application performance. In both manual and vacuum press applications in footwear production, an open time of 5–10 minutes, a pressing time of 10–30 seconds, and an activation temperature of 60–75 °C are considered ideal.

The adhesive must maintain rheological stability during this time, retain reactivation capability on the surface, and quickly establish cohesion after pressing. Especially low-viscosity, sprayable structures ensure more homogeneous distribution, less labor, and reduced consumption. To increase application success, the open time/drying time balance should be optimized according to the production line type and environmental conditions.

4. Performance Criteria

Evaluation of PUD-based systems includes both laboratory and real-world application performance criteria. Multi-dimensional criteria such as adhesion quality, environmental resistance, and integration into the production line determine the industrial suitability of the product.

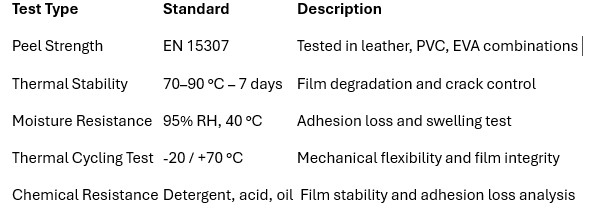

Below is a summary of key performance parameters and relevant methods for testing PUD systems:

These tests provide critical data regarding the product’s service life, safety, and perceived quality—especially for footwear exposed to external conditions (5).

In addition to laboratory tests, formulation optimization is ensured by testing factors such as outsole–upper material combinations, manual/automatic press processes, application temperature, ambient humidity, and daily production rhythm in assembly lines.

In this context, Interplast Kimya’s Aquanex L 066/50 has demonstrated consistent and high performance in both laboratory and field applications on footwear assembly lines. In particular, it meets industrial expectations in terms of peel strength, heat resistance, and moisture stability.

5. Sustainability and Future Outlook

PUD systems offer multi-dimensional advantages not only technically but also environmentally, legally, and in terms of occupational health. Compared to traditional solvent-based systems, they reduce solvent usage by 90–95%, improving both process safety and significantly lowering VOC emissions in the production environment.

These systems:

• Carry no fire risk during application, as they do not contain flammable or explosive solvents

• Contribute to indoor air quality (IAQ) by minimizing odor, smoke, and toxic vapor formation in workspaces

• Are far superior to solvent-based products in terms of worker health, operator comfort, and process safety

PUD systems also show high compliance with many environmental and health standards valid in the European Union and globally. Therefore, increasing the use of water-based systems not only supports sustainable production goals but also provides a competitive advantage in international markets and facilitates certification processes.

6. Conclusion

When designed with the right formulation, controlled film formation, and application optimization, PUD-based adhesives have become fully competitive with solvent-based systems in technical terms. With advantages such as low VOC emissions, high bonding strength, versatile surface compatibility, and easy adaptation to production lines, they meet the footwear industry’s expectations for both environmental responsibility and performance.

Today, being merely "eco-friendly" is not enough; ease of application, cost-efficiency, and contribution to final product quality are also essential. In this regard, PUD-based systems are not a temporary alternative but are becoming a fundamental component of the new generation of production standards.

However, every production line, surface, and process is different. Therefore, companies’ transitions to water-based systems should be guided not by standard formulations, but by application-based optimization processes supported by technical consultation.

The following steps are recommended during implementation:

• Characterization of surfaces

• Evaluation of the adhesive’s drying and activation behavior

• If necessary, receiving primer system recommendations

• Determination of ideal application parameters through field trials

• Integration into production lines with technical support

The purpose of this article is to systematically demonstrate how water-based polyurethane systems can technically respond to the multidimensional challenges—such as bonding, application stability, and environmental restrictions—faced by footwear manufacturers. Through application-specific solutions, field experience, and a formulation engineering approach, companies can achieve not only environmental compliance but also process safety, product quality, and competitive advantage.

References

1. REACH: Regulation (EC) No 1907/2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals – Official Journal of the European Union, 18 December 2006.

2. CLP: Regulation (EC) No 1272/2008 on classification, labelling and packaging of substances and mixtures – Official Journal of the European Union, 16 December 2008.

3. ISO 16000: Indoor air — Part 6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS/FID. International Organization for Standardization, Geneva.

4. Aboelhassan et al., 2017: Aboelhassan, A. M., Ahmed, S. M., Abo El‐Nour, M. M., & Dessouki, A. M. (2017). Waterborne polyurethane dispersions and their recent advances in industrial applications. Journal of Macromolecular Science, Part A, 54(9), 548–561. DOI: 10.1080/01932691.2017.1327818

5. EN 15307: Adhesives for footwear – Test methods for peel strength of bonds, European Committee for Standardization (CEN), 2007.