1. Summary

Slow-release biocide technology purpose is to slow down the release of biocides within a certain time so that designed concentrations from the dry film can be kept within the system longer period.

The principle of slow-release (SR) technology is to keep biocidal actives effective for longer by resisting water leaching, elevated temperatures, high alkalinity, precipitation, and UV irradiation.

2. Introduction

Biofoulings define as the adhesion and growth of organisms on surfaces in contact with water. Algae and fungal growth are observed on the exterior paint film due to external factors by time. Various efforts have been made to combat and prevent biological pollution.

The most common way to prevent biofouling is by adding biocides to paint formulations. Biocides(preservatives) are used in recipes to prevent the formation of these undesirable effects bacterial and fungal growth.

The most revolutionary generation was around 1960 with the advent of Tributyltin based paints (TBT) due to their high antifouling effectiveness and versatility. However, it has shown to be extremely harmful to the ecosystem due to its slow degradation of toxicity. As a result, the use of TBT in antifouling paints was banned in 2008 [1].

Another used biocide is diuron in the dry film protection systems. Diuron becomes active and released from the system when they face external factors. Diuron (3-(3,4-dichlorophenyl)-1,1-dimethylurea) which is used as a dry film preservative in decorative paints belongs to the family of halogeno-phenylurea representing an important herbicide class [2]. It is wettable in the form of a powder and liquid suspension. Diuron is resistant to hydrolysis at pH 5, 7 and 9 [3].

However, Diuron loses its effectiveness in a short time for exterior paints cause of chemical structure and this means it provides short-term protection. Hence, the painted surface degrade easily due to it has low activity.

Alternative studies are carried out with encapsulated biocides that release biocides as the external effects come in and provide longer dry film protection to solve this problem.

In encapsulation technology, the encapsulation process allows the development of durable formulations by keeping a component in a polymer capsule that can be designed to respond to various release triggers (such as pH, temperature, pressure, or dilution) using normally incompatible components.

The release of active substances through the capsule is via diffusion and the rates are a function of their water solubility. There will be different rates of water solubility depending on the activity in question.

This can be controlled by varying the level of encapsulation – enough active materials needed to be released from capsule and available to protect film, but too much and it would leach out.

Using encapsulated biocide in exterior products is aimed to protect the environment and human health by reducing the number of harmful substances leaking from the facade to the floor.

In addition to that color difference problems reduced by improvement of the UV resistance. By reducing water solubility, risk of parasites flowing into ground or water sources by rain also reduced and the outdoor weathering resistance improved. Encapsulated Biocide Image can be seen in Figure 1.

[caption id="attachment_127773" align="aligncenter" width="503"]

![Encapsulated Biocide Image [4]](https://www.turkchem.net/wp-content/uploads/2021/09/figur1.png)

Figure 1. Encapsulated Biocide Image [4][/caption]

3. Experimental

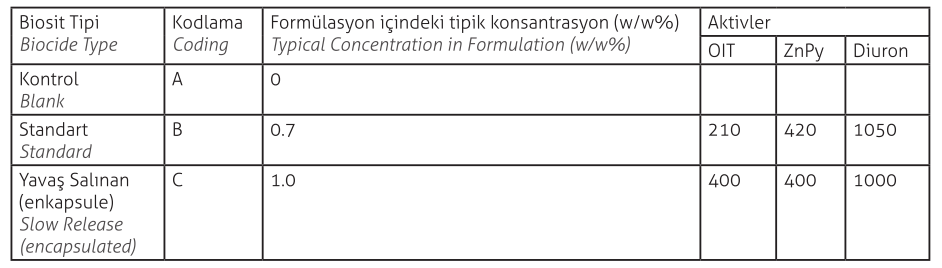

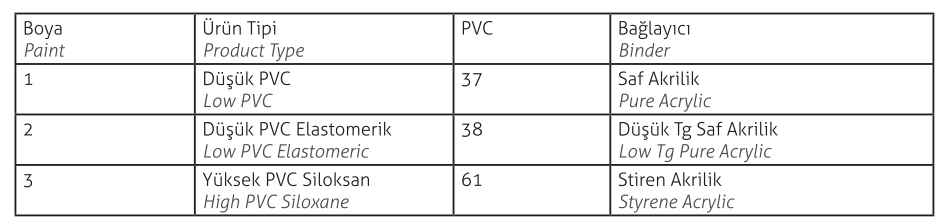

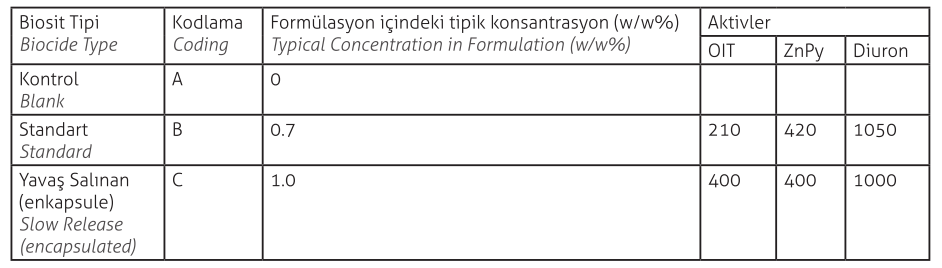

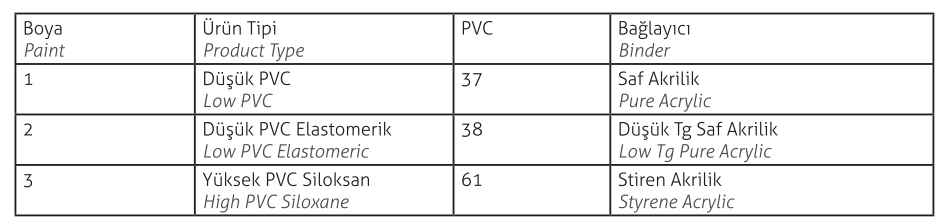

In this study, coating samples were produced by using encapsulated biocide in exterior products. Three different biocides contain external paint formulations were studied in this study. The biocide packs used in the scope of the study was given in Table 1. Tested paint formulations with these biocide packs are given in Table 2. The UV effect was evaluated using the QUV and natural conditioning test in exterior wall paints.

[caption id="attachment_127774" align="aligncenter" width="942"]

Table 1. The biocide packs used in the scope of this study.[/caption]

[caption id="attachment_127775" align="aligncenter" width="948"]

Paints tested in the scope of this study.[/caption]

4. Results and Discussion

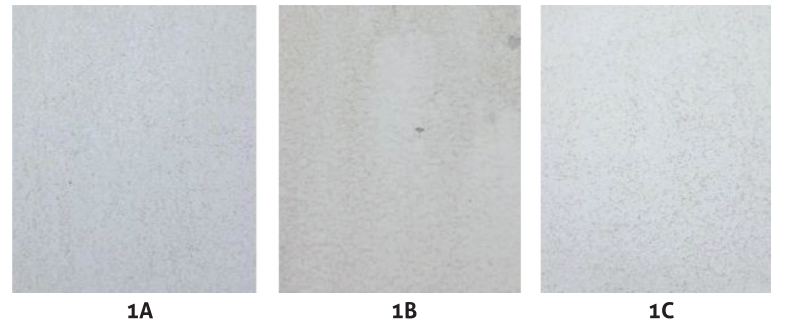

Paints were prepared using different biocide types and at different concentrations in film. Those paints were applied on panels with two coats. The panels were exposed facing South at 45º angle.

The samples were evaluated every 6 months according to ASTM D3274-09 (2013) Standard test method for evaluating the degree of surface disfigurement of paint films by fungal or algal growth, or soil and dirt accumulation.

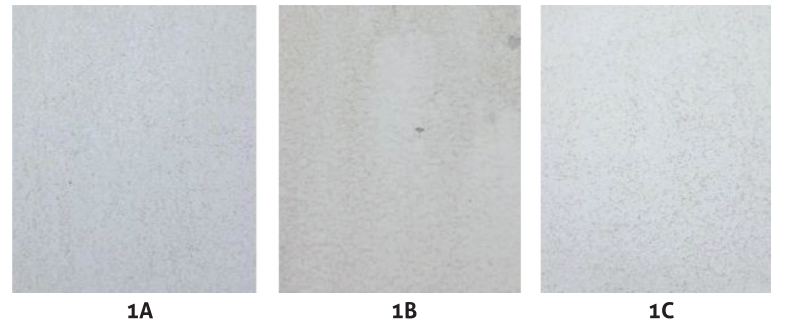

The results mentioned below are 12 months post-exposure evaluation results. Pure Acrylic Low PVC Natural Weathering samples visuals are given in Figure 2.

It was observed that 1 wt% Slow-release encapsulated biocide including paint performed better than 0.7 wt % non-encapsulated standard biocide including paint. Also, paint film appears well without in-film biocide.

[caption id="attachment_127776" align="aligncenter" width="807"]

Figure 2. Pure Acrylic Low PVC Natural Weathering Samples (1A-Control; 1B-Standard; 1C-Encapsulated)[/caption]

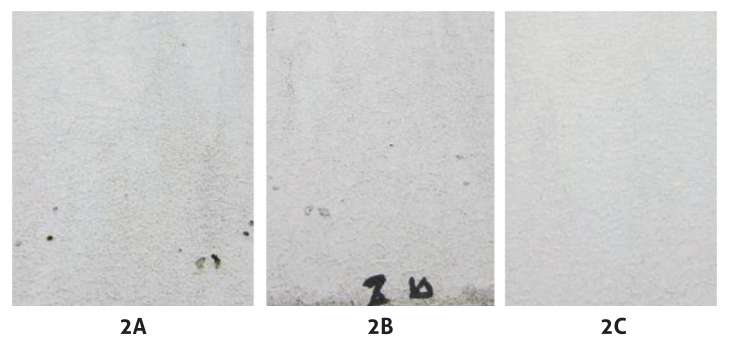

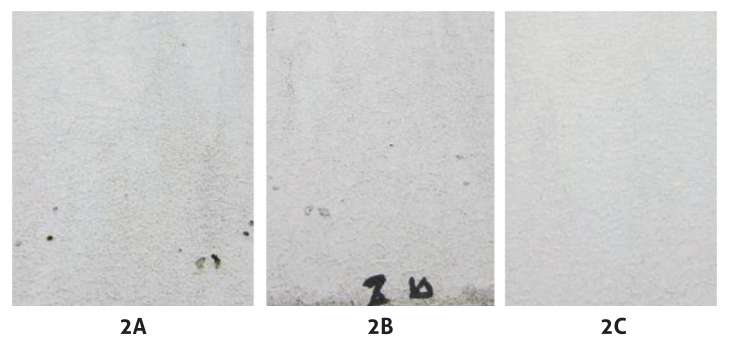

Low Tg Pure Acrylic Natural Weathering samples visuals are given in Figure 3. It was obtained that paint film without biocide appeared worse than with biocide. In addition to that 1 wt % slow release encapsulated performed better than 0.7 wt % non-encapsulated biocide.

[caption id="attachment_127777" align="aligncenter" width="732"]

Figure 3. Low Tg Pure Acrylic Natural Weathering Samples (2A-Control; 2B-Standart; 2C-Encapsulated)[/caption]

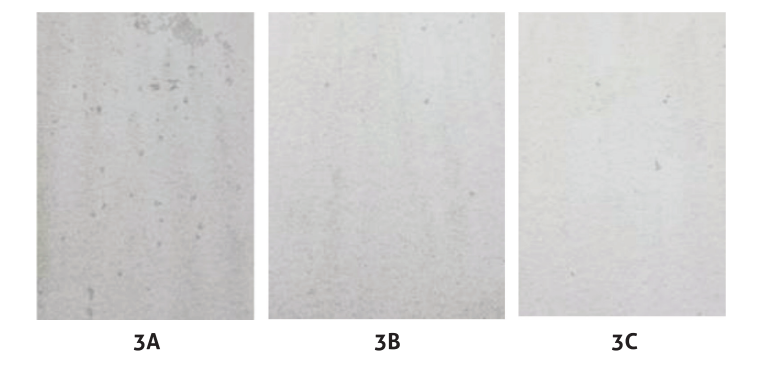

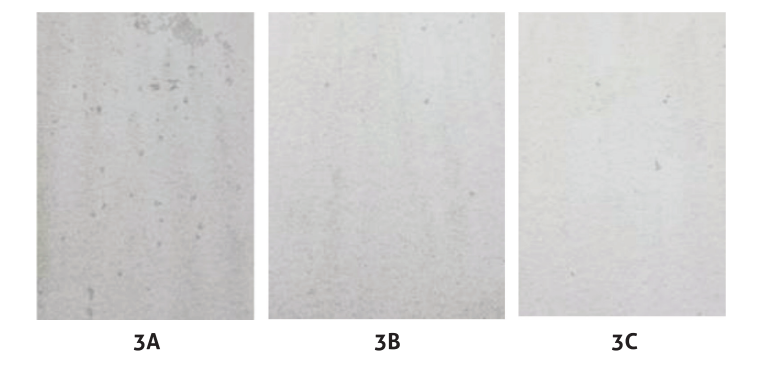

Styrene Acrylic High PVC Siloxane Natural Weathering samples visuals are given in Figure 4. In-film biocide improved the paint film appearance for high PVC siloxane product. Also, 1.0 wt % slow-release biocide contain paint performed better than 0.7 wt % standard nonencapsulated.

[caption id="attachment_127778" align="aligncenter" width="758"]

Figure 4. Styrene Acrylic High PVC Siloxane Natural Weathering Samples (3A-Control; 3B-Standard; 3C-Encapsulated)[/caption]

5. Conclusion

The use of encapsulated biocides in paint recipes is beneficial to prolong the service life and reduce the environmental impact of coatings exposed to the outdoors. An improvement was determined in ΔE after 2000 hours with accelerated QUV and 12 months of natural weathering in this study. It has also been observed that chalking which occurs over time (due to external factors) improves with the use of slow-release encapsulated biocides.

References [1] E. R. Silva, O. Ferreira, J. C. Bordado, M. J. Calhorda, Revestimentos poliméricos para o controlo da bioincrustação industrial: novas estratégias amigas do ambiente, Boletim da Sociedade Portuguesa da Química, 134 (2014) 43-49. [2] Gooddy, D.C., Chilton, P.J., & Harrison, I. (2002). A field study to assess the degradation and transport of diuron and its metabolites in a calcareous soil. Science of the Total Environment, 297 (1-3), 67-83. [3] Çatalkaya Çokay, E. – Degradation and Mineralization of Diuron and Simazine in Aqueous Solution by Advanced Oxidation Processes, Doktora Tezi, Dokuz Eylül Üniversitesi, Fen Bilimleri Enstitüsü, Çevre Mühendisliği Ana Bilim Dalı (2010). [4] R. B Feioa , O. Ferreiraa, J. C. M. Bordadoa, A. C. Marquesa, E. R. Silvaa, Microencapsulation of biocides: a new strategy for biofouling control, https://fenix.tecnico.ulisboa.pt

![Encapsulated Biocide Image [4]](https://www.turkchem.net/wp-content/uploads/2021/09/figur1.png) Figure 1. Encapsulated Biocide Image [4][/caption]

Figure 1. Encapsulated Biocide Image [4][/caption]

Table 1. The biocide packs used in the scope of this study.[/caption]

[caption id="attachment_127775" align="aligncenter" width="948"]

Table 1. The biocide packs used in the scope of this study.[/caption]

[caption id="attachment_127775" align="aligncenter" width="948"] Paints tested in the scope of this study.[/caption]

Paints tested in the scope of this study.[/caption]

Figure 2. Pure Acrylic Low PVC Natural Weathering Samples (1A-Control; 1B-Standard; 1C-Encapsulated)[/caption]

Low Tg Pure Acrylic Natural Weathering samples visuals are given in Figure 3. It was obtained that paint film without biocide appeared worse than with biocide. In addition to that 1 wt % slow release encapsulated performed better than 0.7 wt % non-encapsulated biocide.

[caption id="attachment_127777" align="aligncenter" width="732"]

Figure 2. Pure Acrylic Low PVC Natural Weathering Samples (1A-Control; 1B-Standard; 1C-Encapsulated)[/caption]

Low Tg Pure Acrylic Natural Weathering samples visuals are given in Figure 3. It was obtained that paint film without biocide appeared worse than with biocide. In addition to that 1 wt % slow release encapsulated performed better than 0.7 wt % non-encapsulated biocide.

[caption id="attachment_127777" align="aligncenter" width="732"] Figure 3. Low Tg Pure Acrylic Natural Weathering Samples (2A-Control; 2B-Standart; 2C-Encapsulated)[/caption]

Styrene Acrylic High PVC Siloxane Natural Weathering samples visuals are given in Figure 4. In-film biocide improved the paint film appearance for high PVC siloxane product. Also, 1.0 wt % slow-release biocide contain paint performed better than 0.7 wt % standard nonencapsulated.

[caption id="attachment_127778" align="aligncenter" width="758"]

Figure 3. Low Tg Pure Acrylic Natural Weathering Samples (2A-Control; 2B-Standart; 2C-Encapsulated)[/caption]

Styrene Acrylic High PVC Siloxane Natural Weathering samples visuals are given in Figure 4. In-film biocide improved the paint film appearance for high PVC siloxane product. Also, 1.0 wt % slow-release biocide contain paint performed better than 0.7 wt % standard nonencapsulated.

[caption id="attachment_127778" align="aligncenter" width="758"] Figure 4. Styrene Acrylic High PVC Siloxane Natural Weathering Samples (3A-Control; 3B-Standard; 3C-Encapsulated)[/caption]

Figure 4. Styrene Acrylic High PVC Siloxane Natural Weathering Samples (3A-Control; 3B-Standard; 3C-Encapsulated)[/caption]