RHEOLATE® BIO - Rheology perfection meets sustainability

Rheological effect of biobased NiSAT grades and their contribution to the sustainability of paint formulations.

Numerous kinds of associatively acting rheology modifiers are in the market for aqueous applications. These standard products offer the possibility to tailormade individually required flow characters to meet properties of paints, coatings, adhesives and others based on various binder technologies such as polyurethanes, acrylics, styrene acrylics, Vina-Veova, Vinyl ester, etc. Examples of this product classes are hydrophobic modified acrylic thickeners, so called HASE grades, or NiSAT products, which are known in the market for instance as polyurethane thickeners. Most of the products are available as aqueous liquids for easy handling. Alternatively, powder versions of certain NiSAT grades are available to achieve a better carbon footprint and a biocide and surfactant free thickener.

HASE based grades are anionic, and find mainly use in decorative formulation, e.g. as liquid alternatives to cellulosics. NiSAT thickeners, which term itself abbreviates “Non-ionic synthetic associative thickener”, are of nonionic nature and are offering the most modern approach in formulating water based industrial and decorative coatings. They are acting pH independent over a broad range of applications across all gloss ranges. Further, sag/levelling balance, film build and hiding power can precisely be steered. The influence on the water sensibility and the corrosion of the substrate is very low.

Another huge benefit of the NiSAT pure associative thickeners is the possible addition directly to the system using only moderate shear.

Other ingredients in the formulation will impact the effectiveness of NiSAT range such as co-solvents and surfactants. These effects are relevant for all associatively acting thickeners, independently if they are based on biobased or conventional chemistry.

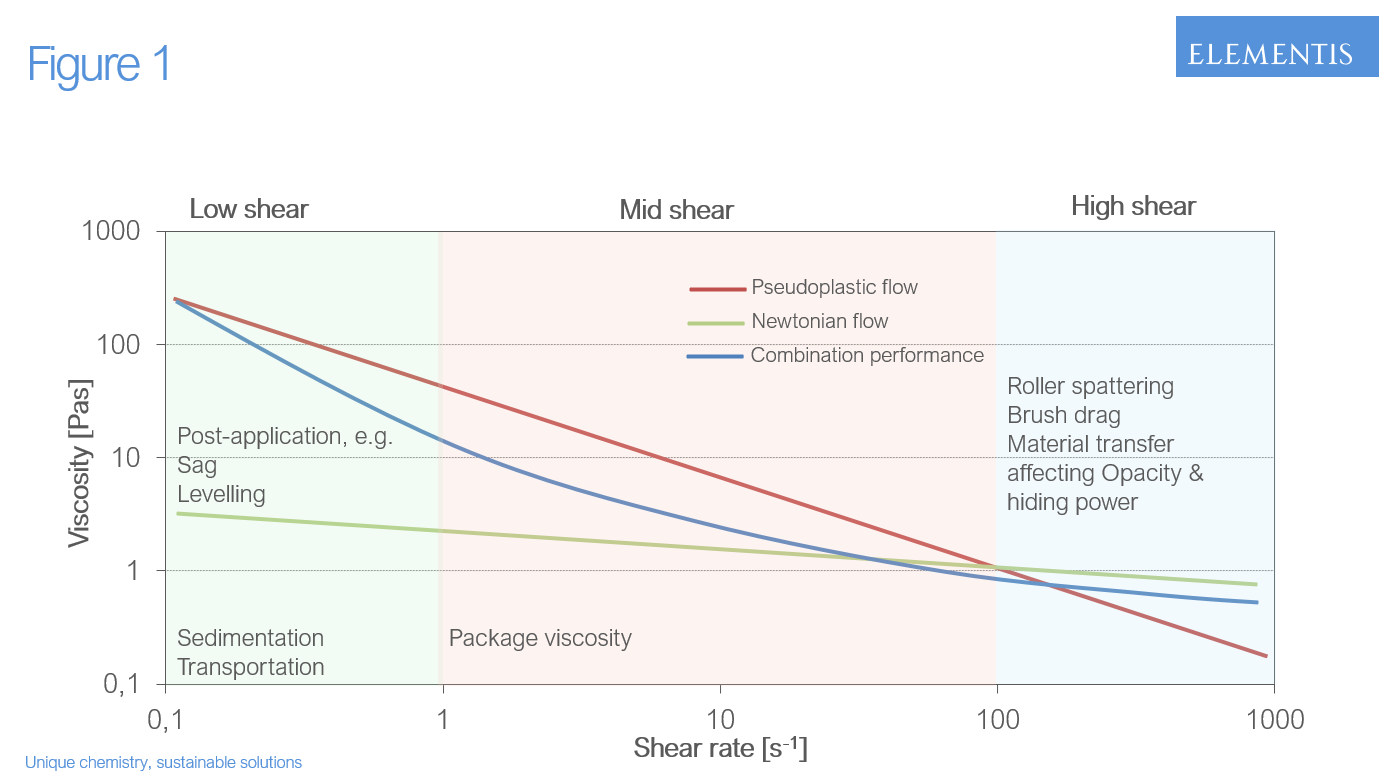

Depending on the choice of NiSAT grades certain shear rate ranges are being affected. Those grades building up low shear viscosity are typically controlling the pre- or post-application behavior e.g. levelling/sag balance and sedimentation. As these products are typically acting shear thinning, the atomization during spray application of industrial coatings can be optimized. So called Newtonian grades are focusing on the high shear side promoting the application behavior like roller spattering, levelling or also the material transfer by a brush drag increase which directly affects the hiding power/opacity.

Typically, these kinds of additives are being combined for a perfect balance of the mentioned properties including the in-can viscosity of the final product.

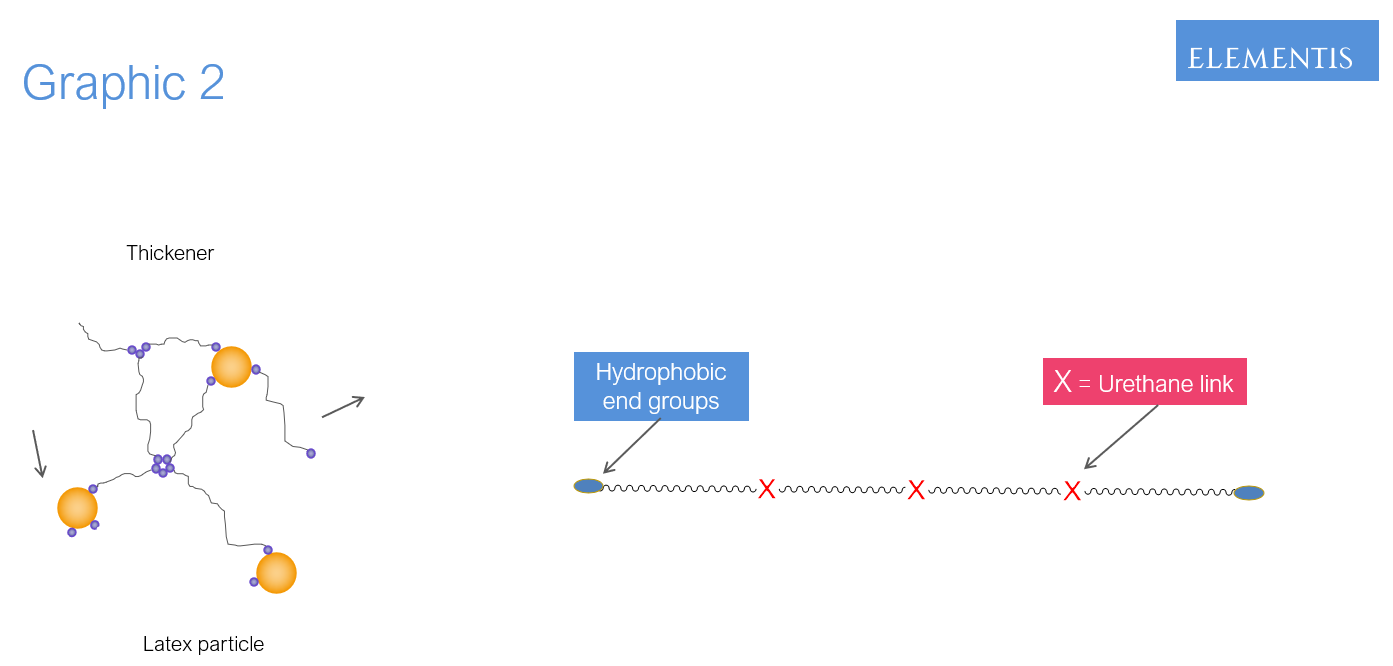

As visualized in Figure 2, NiSAT molecules are typically acting associatively with hydrophobic parts of the formulation such as mainly binders but also to pigments and fillers. This forms network which affects the described rheological effects. The rheologically active molecule consists typically of a hydrophilic, water-soluble backbone, surrounded by at least two hydrophobic end groups. The structure can be linear or branched; this also impacts the performance of the product. The hydrophilic part can be based on conventional raw materials, or, as in the case of the RHEOLATE® BIO products on renewable resources. A molecule weight of typical NiSAT can be typically found in an average range of 20000-50000 g/mol.

The decision, if a NiSAT performs Newtonian or shear thinning is mainly controlled by the strength of the hydrophobic groups. If the hydrophobicity is dominant, the thickener provides shear thinning flow with a strong effect of the low shear viscosity. In the case of less hydrophobic end groups, the molecule focusses on the high shear paired with Newtonian flow driven viscosity by its hydrodynamic volume. In this case, typically the loading levels are higher due to the less pronounced hydrophobicity compared to pseudoplastic grades.

Apart from its pure thickening characteristics, NiSAT products are affecting the viscoelasticity of the end system tremendously. This data is beside the pure viscosity important for a better understanding of the application properties.

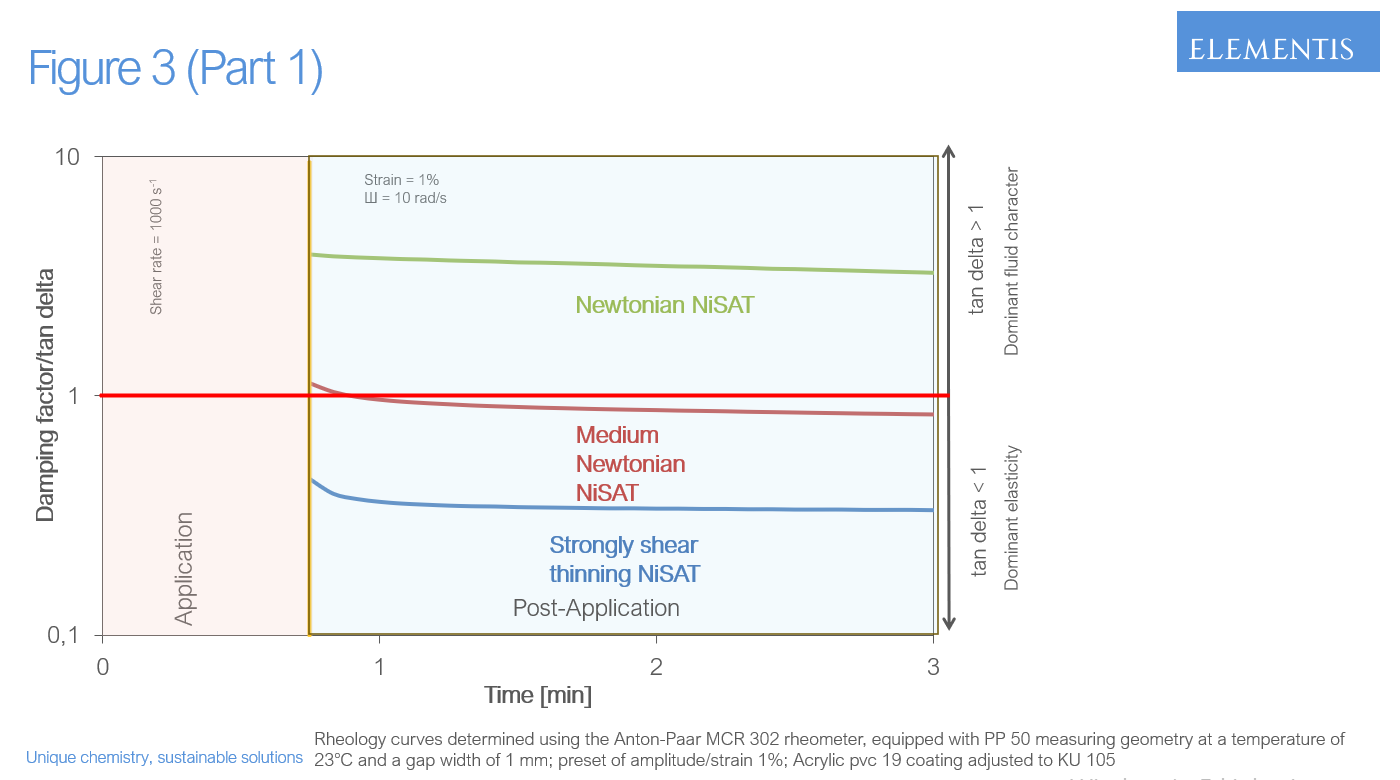

In Figure 3 the structure recovery test data of a pure acrylic, PVC 19, paint formulations equipped with various NiSAT thickeners a visualized as damping factor, or tan delta value.

The damping factor have been generated in an oscillatory, structure recovery test which simulates a coating application. The first part of the diagram shows a rotational high shear part. As only oscillatory tests are generating these data, this part of the diagram remains void. In the second part, the post-application properties are shown. Strain and angular frequency were presets to a low range, in which the behavior is usually elastic dominated. As in the rotational part all structure has been broken, the exact time of the recovery can be read off when plotted on a time scale. A damping factor of below 1, shows a dominant elastic character whilst a value of above one describes Newtonian, fluid like behavior.

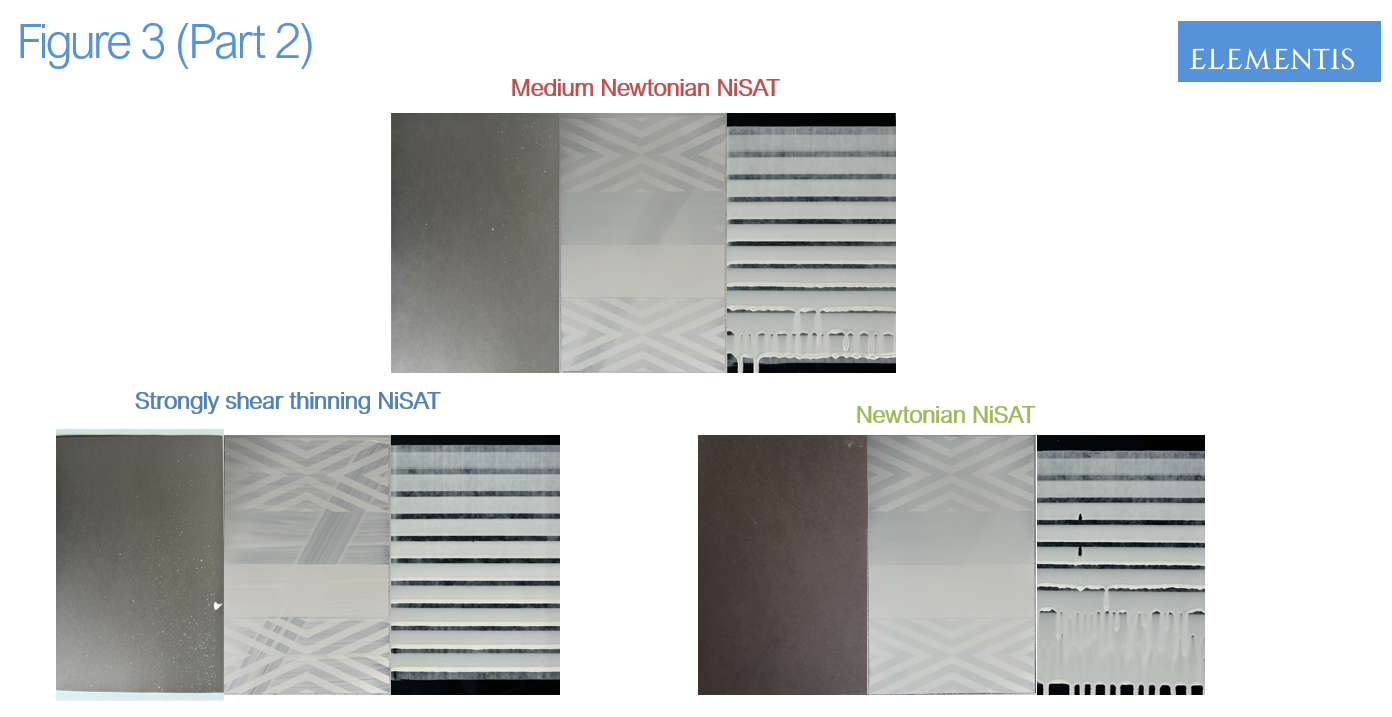

In the case of the strongly pseudoplastic NiSAT grade, the tan delta value acts significantly below 1 indicating a strong elastic character. In a context with the application results, this guides to good sag control, however, levelling and spatter resistance, were a bit inferior. On the other hand, a Newtonian rheology modifier gives better levelling and spatter resistance, whilst the sag control remains behind. Damping factor in this case is far above 1 which displays a strong fluid character and practically no structure. The medium Newtonian grade acts in between offering the best sag/levelling balance indicated by a tan delta value of roughly around 1.

From a sustainable perspective, it becomes obvious that the hydrophilic, water-soluble main part of the NiSAT active raises the highest interest as it represents depending on the product up to 95% of the entire molecule mass. Consequently, this part has the strongest influence when made from renewable resources. As already explained, chemically this part of the molecule consists of a polyol chain. In the new biobased NiSAT product family, this part has been based on bioethanol originated by sugarcane molasses. This raw material is classified as waste or residue as it is not intentionally produced. Consequently, it does not compete with food supply.

The use of biobased polyol allows the content of biobased carbon content to be higher than 90% determined by the biobased carbon C14 segregated approach.

The current range of biobased NiSAT’s consists of two grades, RHEOLATE® BIO 5010 a Newtonian and with RHEOLATE® BIO 5075 a pseudoplastic acting grade. Formulated alone or combined even with other classes of rheology modifiers e.g. clays, acrylic thickeners or cellulosics, the adjustment of the desired flow characteristic is guaranteed.

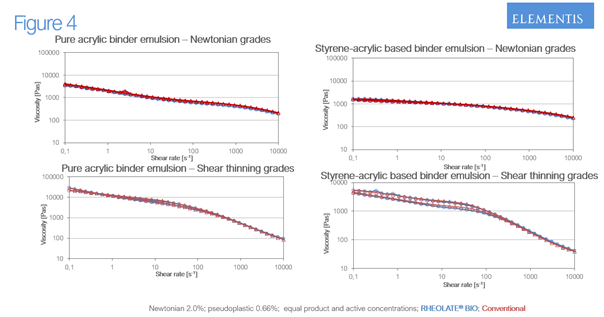

Comparing the pseudoplastic RHEOLATE® BIO 5075 to its conventional counterpart it becomes visible that the rheological performance of both grades acts very closely. The rheograms were determined in a standard PVC 50 paint exemplary equipped either with a styrene-acrylic and a pure acrylic binder emulsion. The concentration added was in both cases 0.66%. As the active content with both additives are identical, the content of rheologically active material in the system was equal as well.

A very similar picture can be taken when comparing RHEOLATE® BIO 5010, the Newtonian grade, to its conventional equivalent. Also in this case, the active content in both products have been identical. Consequently, the added thickener concentration of 10.5% the styrene-acrylic and 5% to the pure acrylic result in both cases in equal active loading as well.

In all cases the rheological characteristics are very similar, so that a 1:1 replacement from the conventional to the biobased version can be realized without affecting the rheological characteristics adversely.

However, to simulate the behavior under real conditions, both, Newtonian and pseudoplastic, rheology modifiers must be combined. Only in that case, the rheological characteristics can be perfectly equalized for balanced sag, levelling, workability and other characteristics required. For this study, the styrene-acrylic based PVC 50% paint was selected.

As a base viscosity for this and to compare the efficiency of the individual additive combinations to each other the Krebs-Stormer and the high shear viscosity at 10000 s-1 was taken. The Krebs-Stormer (KU) viscosity is often taken to represent the in-can viscosity and acts approximately in a shear rate range of 100-200 s-1. Due to the conditions in KU measurement an accurate shear rate cannot be calculated. Consequently, the result will be measured just unitless.

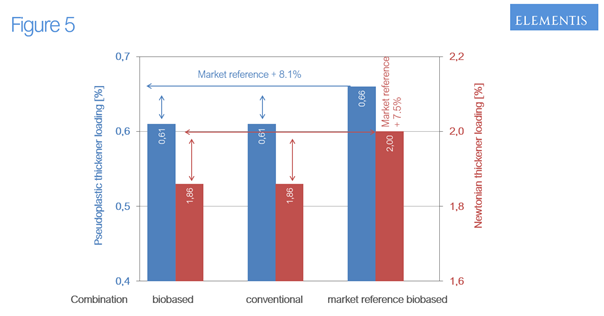

In the given case displayed in Figure 5, the KU viscosity has been adjusted to roughly 100 units whilst the high-shear viscosity was set to about 1.1 Poise.

In the case of the RHEOLATE® BIO combination and the blended conventional RHEOLATE® grades the required concentration to obtain the mentioned viscosity values are equal and confirmed therefore the findings of the individual testing. However, when comparing the equal the active containing biobased market reference grades, it becomes obvious that these are requiring higher loading levels for the same effect. In the case of the Newtonian, it was 7.5%, the pseudoplastic side required 8.1% more.

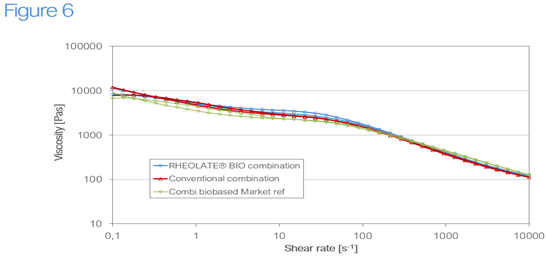

The resulting rheogram, visualized in Figure 6, shows that equally pre-adjusted paints are acting very similar.

Differences could only be noticed on the low shear side, in which the market reference combination produces somewhat lower values. In the mid shear rate range between 10 s-1 and 100 s-1 a slight dominance of the RHEOLATE® BIO combination can be seen.

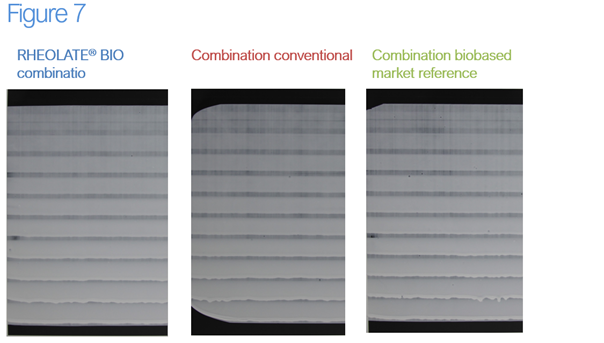

However, besides the pure rheological characteristics, further application properties are being of high importance and are influenced by the choice of rheology modifiers. The in this case evaluated and shown properties are levelling up on brush application, sag control, roller spattering resistance and storage stability are visualized in the Figures 7-11. Further properties such as dirt-pick-up, staining resistance etc. of the final paint have been tested as well and can be shared on demand.

It is becoming obvious that changing from conventional to RHEOLATE® BIO NiSAT grades no remarkable changes in the application properties are noticed. Also, in comparison to the combination of the market reference biobased products no properties have been majorly changed.

However, the sag control displayed in Figure 7 with the biobased market reference thickeners is remaining slightly behind. These findings are in line with the rheological findings on the low-mid shear side which were discussed earlier.

Levelling after brush application shown in Figure 8, the so-called brush out properties, showed in all cases the same behaviour. Also, no visual differences in the opacity were seen. For this test the same amount of 40 g of all three-test paint was brought on the brush. After the application by identical number of brush swings, the material amount really transferred to the substrate was calculated back to ensure similar paint transfer.

In the case of the material stored for 28 days at 50 °C in Figure 9 stable conditions were noticed. Only minor syneresis was seen.

Brush applied demonstrated in Figure 10 is showing no differences in between the differently tested paint samples. For this test, again an equal amount of 200 g of paint was placed on a roller. During the 10 roller applications swings on a vertical, potential spatters are being collected on a black leneta chart positioned underneath. The lower the number of spatters collected the better the result and the better the rating.

Besides the test paint system shown in this publication our RHEOLATE® BIO products have been tested in further systems equipped with different binder emulsions.

Conclusion

NiSAT thickeners are acting associativity with hydrophobic parts of the final formulations. Depending on the chemical composition and its hydrophilic/hydrophobic balance of the thickener molecules certain areas of the shear rate scale can be affected. This allows exact steering of the flow characteristics of paints and other aqueous systems by individual or combined choice of rheology modifiers. Those kinds of properties can be underlined by relevant rheological measurements displaying flow characteristics and viscoelastic data.

Watching the chemical structure, it becomes obvious that a large part of the rheologically active molecule can be formulated by biobased renewable resources for a strong impact on the sustainability of the product and the final formulation. Elementis new biobased products, RHEOLATE® BIO 5010, a Newtonian, and RHEOLATE® BIO 5075, a pseudoplastic acting thickener, are consisting of minimum 90% C14 verified biobased carbon.

From a functional point of view both RHEOLATE® BIO 5010 and RHEOLATE® BIO 5075 grades are in line with its conventional counterparts showing only minor differences in the flow characteristics and application properties provided. In comparison to commercially available biobased market reference thickeners with equal application spectrum, the new product line performs dominant in the terms of efficiency and provided sag control.

Based on these results, the new line of RHEOLATE® BIO grades offers further options to further parts of paint formulations for a better fit of rheological perfection with the nowadays required sustainable facts.

Literature

Elementis rheology handbook

Udo Schonhoff –Author

Teknik Satış Müdürü, Performans Uzmanlıkları

Technical Sales Manager Performance Specialties

Elementis GmbH

Çise Karamehmetoğlu –Compiled by

Satış Müdürü

Sales Manager

Fuchs Kimya A.Ş.

Fırat Pınar –Compiled by

Satış Müdürü

Sales Manager

Fuchs Kimya A.Ş.