New Generation Horizontal Bead Mills

In addition to the increasing demand for high product quality in all chemical sectors, especially the paint / coating sector, the need for efficiency against increasing costs also brings the necessity of better grinding performance in products that require solid-liquid dispersion.

The simplest example; in paint production, while stronger colors are desired, it is also desired to keep the pigment consumption at a minimum, to shorten the process time and to reduce the amount of unit energy used for production. The way to achieve all this

is to ensure that the wet grinding process is as powerful and efficient as possible during the production process.

As Yokeş® Makina, which has been providing solutions to the sector for a long time in this regard, we continue to offer the highest level of wet grinding solutions with the research and innovation studies we have carried out both with our solution partners and within

our own body. We respond to the requirements and demands of the day by following the technological developments in our sector, applying them to our machine designs and putting the innovations into use.

We present the latest result of these efforts as the new Powermill-Convecta® and Powermill-Performa® series horizontal wet grinding machines, which we call Yokeş®’s 4th generation in our horizontal wet grinding machines.

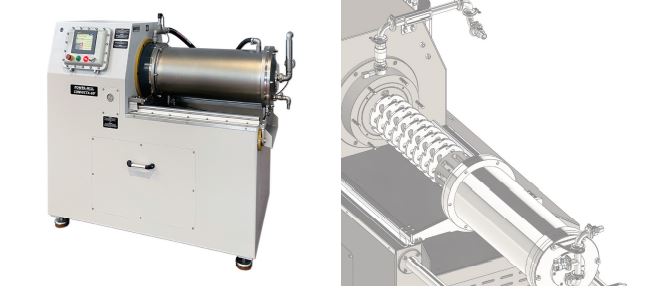

High Flow Conventional Bead-Mill:

Powermill-Convecta®

Powermill-Convecta® is the latest and advanced model of Conventional Horizontal Type Bead Mill / Wet Grinding Machines that Yokeş® Makina has been producing for more than 25 years. It is categorized as “High Flow Bead Mill”. Thanks to the strong structure of the agitator discs and the specially designed separation system, very high flow and grinding speeds can be easily achieved. The movement required for wet grinding is transmitted to the grinding beads by means of agitator discs, which are mounted on the main shaft of the

machine and can be easily disassembled. The material to be grinded is fed to the machine by a separate pump.

The efficiency of the machine depends on the energy given to the grinding chamber and the behavior of this energy in the wet grinding process. PowermillConvecta® has a very high efficiency with its suitable grinding chamber geometry and parameters.

hanks to the ideal diameter / length ratio of the grinding chamber and the special design of the agitator discs, the available energy is used in the most efficient way, the condensation of the grinding beads in certain areas in the chamber is prevented. It can be easily adapted even to difficult wet grinding conditions.

General Features-Innovations

Grinding chambers of Powermill-Convecta® Bead Mills have a very powerful helical grinding chamber cooling system. This cooling system is designed to provide maximum heat transfer from the grinding chamber to the cooling water. In this way, the product heating

problem that occurs during the wet grinding process is completely eliminated.

Maximum shaft sealing is ensured by the specially designed cartridge type, double-acting mechanical seal for Yokeş®, and the shaft seal can be changed very quickly and practically. The mechanical seal cooling / rinsing system is also water cooled. The seal inner barrier liquid pressure can be adjusted according to the product pressure. Main shaft is Stepless Speed Controlled by Frequency Converter. In this way, it is possible to work at desired speeds in order to get the most efficient results during the process.

A gear type product feeding pump with frequency converter and stepless speed / flow control, made of Yokeş® with 1 ¼ inch inlet and outlet is used.

According to the product type, two separation systems are offered for the grinding beads - product separation:

1) Tungsten Carbide, Rotating / Fixed GAP Separator System: GAP spacing can be adjusted according to the bead diameter.

2) Sieve Separator System: Bead-product separation on the product outlet side of the machine is provided by “Yokeş® - WDG System High Flow Cylindrical Sieve Separator”. By means of the advanced PLC control system, all machine controls, monitoring of process parameters and setting of machine limit values can be easily done by the machine operator.

For the detailed cleaning of the machine, there is a ball bearing sled system that allows the grinding chamber to be opened and closed easily. All materials used in the machine are selected to provide high wear resistance and maximum part life in line with maximum

quality requirements. According to the type of product to be grinded, specific steel, materials, ceramic derivatives, sintered carbide materials and high quality stainless steel materials are used.

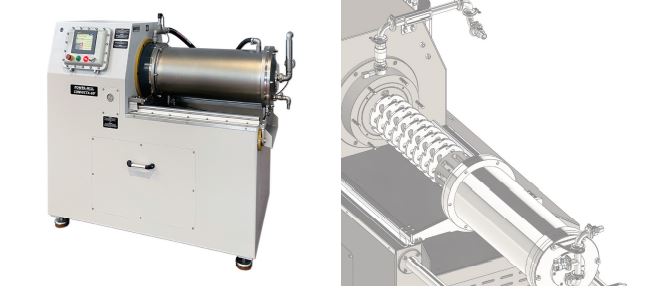

High Efficiency Bead-Mill:

Powermill-Performa®

Powermill-Performa® is a new generation machine designed with the aim of reaching higher capacity, faster wet grinding and higher fineness values in a short time compared to standard horizontal wet grinding machines. Thanks to the possibility of using very small grinding beads, very high grinding speeds can be achieved, and thanks to the small amount of beads used during the process, it can work with lower energy consumption.

General Features-Innovations

They can work with circulation or tank-to-tank pass system. The energy and motion required for highcapacity wet grinding are transmitted to the grinding beads by a specially designed Rotor-Pin System. With its special grinding chamber design and rotor-pin system, Powermill-Performa® series machines can reach the narrowest possible particle size distribution in a shorter time.

The special design of the grinding chamber and rotorpin system allows the beads in the chamber to move against the direction of the product flow, ensuring the self-cleaning of the product exit sieve and increasing the wet grinding efficiency by creating the most comfortable uniform product flow possible.

The grinding beads movement and collisions within the grinding chamber are much faster compared to a conventional horizontal bead-mill. When the flow of product in the opposite direction of the bead turning is added to this movement, the product passing speeds and machine performance increase significantly. In addition, the bead + product movement,

completely independent of turbulence in the grinding chamber, plays an important role in increasing the life of the grinding beads.

All materials used in this machine are selected to provide high wear resistance and maximum part life in line with maximum quality requirements. According to the type of product to be grinded, specific steel materials, ceramic derivatives, sintered carbide materials and high quality stainless steel materials are used.

Bead-product separation on the product outlet side of the machine is provided by “Yokeş®-WDG System High Flow Cylindrical Sieve Separator”. For maximum flow, the sieve surface is designed as large as possible within the machine limits. The special structure of the

rotor disc and the cover is such that the sieve surface is constantly cleaned while the machine is running.When there is a blockage in the sieve, the inside of the sieve can be cleaned without opening the machine, only by intervening from the front cover.

Thanks to the high-flow sieve system, it is possible to use grinding beads of all sizes in the wet grinding process (min. 0.1mm) and the desired ultra-fineness values can be easily achieved in the product.

Powermill - Performa® grinding chambers have a very powerful helical grinding chamber cooling system. This cooling system is designed to provide maximum heat transfer from the grinding chamber to the cooling water. In this way, the product heating problem

that occurred during the high-efficiency wet grinding process is completely eliminated.

By means of the advanced PLC control system, all machine controls, monitoring of process parameters and setting of machine limit values can be easily done by the machine operator. The main shaft is stepless speed controlled. In this way, it is possible to work at desired

speeds in order to get the most efficient results during the process. After the grinding process is finished, low cycle washing can be done to wash the inner chamber of the machine.

Advantages of Powermill - Performa® Series

Thanks to its special design, with its small grinding chamber volume and low bead amount, more wet grinding results can be achieved in a shorter time than conventional Bead Mills can achieve with large volume and large amount of beads.

Thanks to the small process volume, cleaning, maintenance, product change, bead change, disc change, etc. work can be done in a very practical way. Machine downtimes are shortened considerably. The amount of materials used for cleaning is very small.

Maximum shaft sealing is ensured by the specially designed cartridge type, double-acting mechanical seal for Yokeş®, and the shaft seal can be changed very quickly and practically. The mechanical seal cooling / rinsing system is also water cooled. The seal inner barrier liquid pressure can be adjusted according to the product pressure. All this ensures that the mechanical seal can be used for a long time without any problems. Thanks to the small process volume and effective cooling system, wet grinding of heat sensitive special

products can be easily controlled. Thanks to the small compact structure of the Powermill-Performa® Series, production costs and maintenance costs are very low.

Our Powermill - Performa® Series machines can work in a wide range of products thanks to their wide capacity range, modular structure and flexibility. General usage areas are the production of all Paint and By-products, the production of Flexo and Rotogravure Printing Inks, the production of water and solvent-based Inkjet Inks, the productions for the platn protection / plant feeding sector, etc. can be classified as. Both of our models have different grinding chamber volume and motor power options according to the required capacity, and

they have Standard IP or Ex-Proof protection class options.

We would like to introduce you our Yokeş® 4th generation Wet Grinding Machines so that you can make your processes much more efficient and your product quality much higher.

Onur Ovalı

Sales & Marketing Manager

Yokeş Makina A.Ş.

Maximum shaft sealing is ensured by the specially designed cartridge type, double-acting mechanical seal for Yokeş®, and the shaft seal can be changed very quickly and practically. The mechanical seal cooling / rinsing system is also water cooled. The seal inner barrier liquid pressure can be adjusted according to the product pressure. Main shaft is Stepless Speed Controlled by Frequency Converter. In this way, it is possible to work at desired speeds in order to get the most efficient results during the process.

A gear type product feeding pump with frequency converter and stepless speed / flow control, made of Yokeş® with 1 ¼ inch inlet and outlet is used.

According to the product type, two separation systems are offered for the grinding beads - product separation:

1) Tungsten Carbide, Rotating / Fixed GAP Separator System: GAP spacing can be adjusted according to the bead diameter.

2) Sieve Separator System: Bead-product separation on the product outlet side of the machine is provided by “Yokeş® - WDG System High Flow Cylindrical Sieve Separator”. By means of the advanced PLC control system, all machine controls, monitoring of process parameters and setting of machine limit values can be easily done by the machine operator.

For the detailed cleaning of the machine, there is a ball bearing sled system that allows the grinding chamber to be opened and closed easily. All materials used in the machine are selected to provide high wear resistance and maximum part life in line with maximum

quality requirements. According to the type of product to be grinded, specific steel, materials, ceramic derivatives, sintered carbide materials and high quality stainless steel materials are used.

Maximum shaft sealing is ensured by the specially designed cartridge type, double-acting mechanical seal for Yokeş®, and the shaft seal can be changed very quickly and practically. The mechanical seal cooling / rinsing system is also water cooled. The seal inner barrier liquid pressure can be adjusted according to the product pressure. Main shaft is Stepless Speed Controlled by Frequency Converter. In this way, it is possible to work at desired speeds in order to get the most efficient results during the process.

A gear type product feeding pump with frequency converter and stepless speed / flow control, made of Yokeş® with 1 ¼ inch inlet and outlet is used.

According to the product type, two separation systems are offered for the grinding beads - product separation:

1) Tungsten Carbide, Rotating / Fixed GAP Separator System: GAP spacing can be adjusted according to the bead diameter.

2) Sieve Separator System: Bead-product separation on the product outlet side of the machine is provided by “Yokeş® - WDG System High Flow Cylindrical Sieve Separator”. By means of the advanced PLC control system, all machine controls, monitoring of process parameters and setting of machine limit values can be easily done by the machine operator.

For the detailed cleaning of the machine, there is a ball bearing sled system that allows the grinding chamber to be opened and closed easily. All materials used in the machine are selected to provide high wear resistance and maximum part life in line with maximum

quality requirements. According to the type of product to be grinded, specific steel, materials, ceramic derivatives, sintered carbide materials and high quality stainless steel materials are used.

Powermill - Performa® grinding chambers have a very powerful helical grinding chamber cooling system. This cooling system is designed to provide maximum heat transfer from the grinding chamber to the cooling water. In this way, the product heating problem

that occurred during the high-efficiency wet grinding process is completely eliminated.

By means of the advanced PLC control system, all machine controls, monitoring of process parameters and setting of machine limit values can be easily done by the machine operator. The main shaft is stepless speed controlled. In this way, it is possible to work at desired

speeds in order to get the most efficient results during the process. After the grinding process is finished, low cycle washing can be done to wash the inner chamber of the machine.

Powermill - Performa® grinding chambers have a very powerful helical grinding chamber cooling system. This cooling system is designed to provide maximum heat transfer from the grinding chamber to the cooling water. In this way, the product heating problem

that occurred during the high-efficiency wet grinding process is completely eliminated.

By means of the advanced PLC control system, all machine controls, monitoring of process parameters and setting of machine limit values can be easily done by the machine operator. The main shaft is stepless speed controlled. In this way, it is possible to work at desired

speeds in order to get the most efficient results during the process. After the grinding process is finished, low cycle washing can be done to wash the inner chamber of the machine.