Halved Carbon Footprint

DSM Engineering Materials introduces 100% bio-based Stanyl® with a halved carbon footprint and the same high performance to empower customer sustainability.

DSM Engineering Materials announces the launch of a new, more sustainable version of its flagship product Stanyl®: Stanyl® B-MB (Bio-based Mass Balanced), with up to 100% bio-based content.

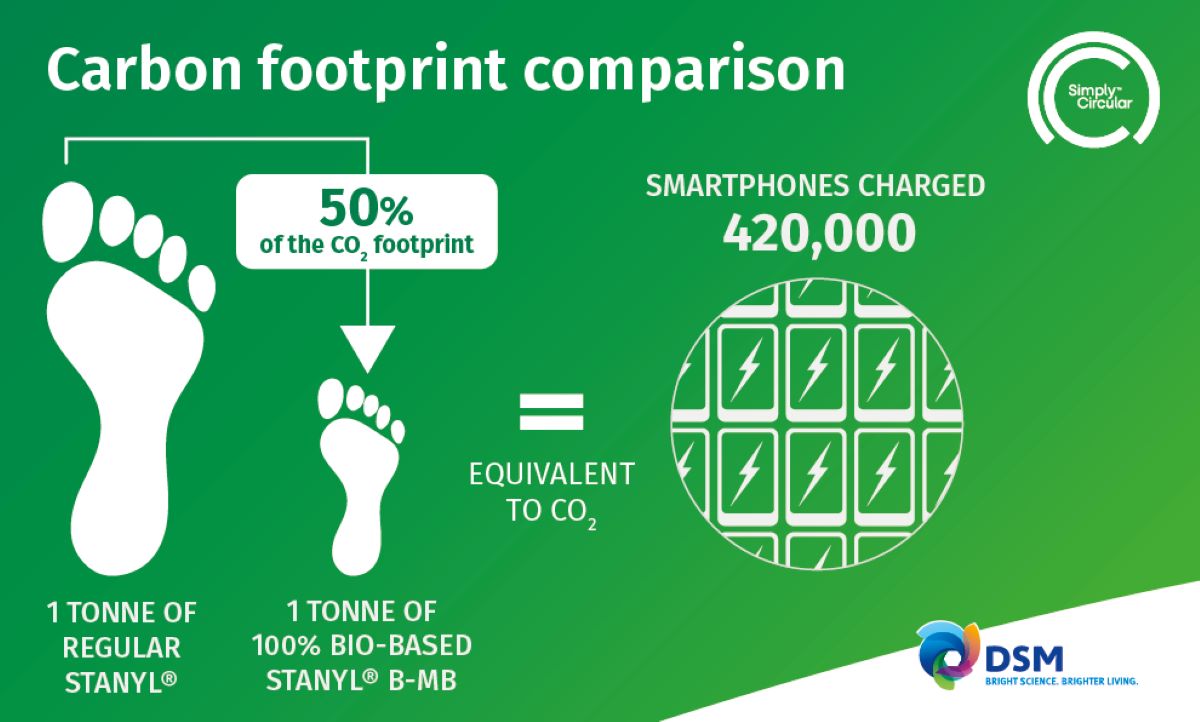

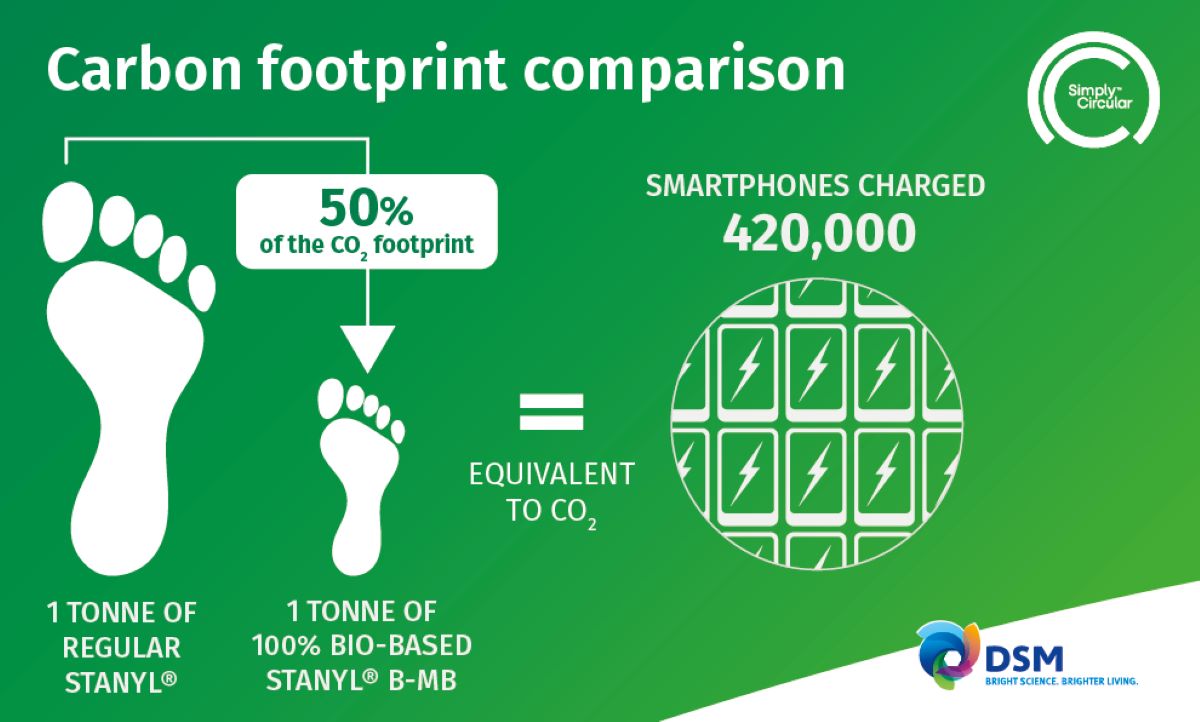

Using the highest possible levels of biomass-waste feedstock, DSM Engineering Materials is able to cut in half the carbon footprint of this product line, and thus of its customers' Stanyl® B-MB-based products.

This industry-first launch of a 100 percent bio-based high-temperature polyamide underscores the company's ongoing commitment to assisting customers in achieving their sustainability goals by making planet-positive choices and assisting in the transition to a circular and bio-based economy.

Global bio-based product production nearly doubled between 2015 and 2020, but in order to conserve the planet's natural resources and stay below the critical 1.5 degrees of global warming, the materials industry must urgently accelerate the transition to sustainable feedstocks. DSM Engineering Materials has committed to providing bio- and/or recycled-based alternatives for its entire portfolio by 2030, recognizing this need.

Stanyl® B-MB – now available with up to 100% bio-based content – is a fully ISCC+-certified mass-balancing solution, and delivers exactly the same characteristics, performance, and quality as conventional Stanyl®. In addition, production of Stanyl® B-MB now generates a carbon footprint up to 50% lower than the fossil-based original. In practice, this means a 3.3-ton CO2 reduction per ton produced – equivalent to charging 420,000 smartphones.

Not only does this industry first further support the ‘Sustainable sourcing’ pillar of DSM Engineering Materials’ SimplyCircular™ initiative, but it also raises the bar for biomass-balanced solutions in the industry. DSM Engineering Materials therefore continues to lead the way on driving carbon-footprint reductions and boosting customers’ environmental success.

[caption id="attachment_141927" align="aligncenter" width="1200"]

Photo: DSM Engineering Materials: DSMPR534[/caption]

Roeland Polet, President DSM Engineering Materials: “With both consumers and regulators demanding more sustainable materials, the launch of 100% bio-based Stanyl® B-MB is an important step forward for our industry. We are fully committed to developing sustainably sourced products with a reduced environmental impact. With the same specifications and performance but with a 50% lower carbon footprint, this new portfolio will enable our customers to fulfil their sustainability goals and contribute to a planet-positive future – so what they design today, we can all value tomorrow.”

Stanyl® B-MB continues Stanyl®’s 30-year legacy of meeting customers’ most stringent performance requirements. The only aliphatic polyamide in its class, Stanyl® redefined polyamides when it was introduced, and is still the most widely used high-temperature polyamide today.

Its excellent high-temperature mechanics, superior flow and processing, and distinguished wear and friction resistance make it ideal for high-temperature applications in automotive, electronics, electrical, and consumer goods industries, such as USB connectors, automotive and industrial actuator gears, powertrain timing chains, bearing cages, and food contact conveyors.

Note: Content may be edited for style and length.

Source

Photo: DSM Engineering Materials: DSMPR534[/caption]

Roeland Polet, President DSM Engineering Materials: “With both consumers and regulators demanding more sustainable materials, the launch of 100% bio-based Stanyl® B-MB is an important step forward for our industry. We are fully committed to developing sustainably sourced products with a reduced environmental impact. With the same specifications and performance but with a 50% lower carbon footprint, this new portfolio will enable our customers to fulfil their sustainability goals and contribute to a planet-positive future – so what they design today, we can all value tomorrow.”

Stanyl® B-MB continues Stanyl®’s 30-year legacy of meeting customers’ most stringent performance requirements. The only aliphatic polyamide in its class, Stanyl® redefined polyamides when it was introduced, and is still the most widely used high-temperature polyamide today.

Its excellent high-temperature mechanics, superior flow and processing, and distinguished wear and friction resistance make it ideal for high-temperature applications in automotive, electronics, electrical, and consumer goods industries, such as USB connectors, automotive and industrial actuator gears, powertrain timing chains, bearing cages, and food contact conveyors.

Note: Content may be edited for style and length.

Source

Photo: DSM Engineering Materials: DSMPR534[/caption]

Roeland Polet, President DSM Engineering Materials: “With both consumers and regulators demanding more sustainable materials, the launch of 100% bio-based Stanyl® B-MB is an important step forward for our industry. We are fully committed to developing sustainably sourced products with a reduced environmental impact. With the same specifications and performance but with a 50% lower carbon footprint, this new portfolio will enable our customers to fulfil their sustainability goals and contribute to a planet-positive future – so what they design today, we can all value tomorrow.”

Stanyl® B-MB continues Stanyl®’s 30-year legacy of meeting customers’ most stringent performance requirements. The only aliphatic polyamide in its class, Stanyl® redefined polyamides when it was introduced, and is still the most widely used high-temperature polyamide today.

Its excellent high-temperature mechanics, superior flow and processing, and distinguished wear and friction resistance make it ideal for high-temperature applications in automotive, electronics, electrical, and consumer goods industries, such as USB connectors, automotive and industrial actuator gears, powertrain timing chains, bearing cages, and food contact conveyors.

Note: Content may be edited for style and length.

Source