Slipper samples cast with our new polyurethane system introduced to the market can be seen in the Figure 1.

Slipper samples cast with our new polyurethane system introduced to the market can be seen in the Figure 1.

While polyurethane systems which generally provide high hardness value are used in slippers products, the search of the producers has shifted towards low hardness values due to the increasing comfort and comfort expectations of consumers in recent years.

For this reason, our company has created a significant difference in the industry in customer-oriented studies with the new system developed 40-45 shore A hardness value of slippers aimed at providing high flexibility value.

The flex-resistance test carried out according to TS EN ISO 17707 standard, the growth in the notch opened after 30,000 steps was found to be <4 mm and a very superior performance was obtained compared to the systems used in this market.

While polyurethane systems which generally provide high hardness value are used in slippers products, the search of the producers has shifted towards low hardness values due to the increasing comfort and comfort expectations of consumers in recent years.

For this reason, our company has created a significant difference in the industry in customer-oriented studies with the new system developed 40-45 shore A hardness value of slippers aimed at providing high flexibility value.

The flex-resistance test carried out according to TS EN ISO 17707 standard, the growth in the notch opened after 30,000 steps was found to be <4 mm and a very superior performance was obtained compared to the systems used in this market.

Flokser Chemical is leading the industry by understanding the needs of the manufacturers with its wide range of products. One of the most important requirements in recent times is the development of slipper systems which have the same properties but can be applied at lower molding densities.

We are introducing an ultra-lightweight slippers system to satisfy the user’s interest in ergonomics and to enable the manufacturer to produce slippers with the same features but less weight.

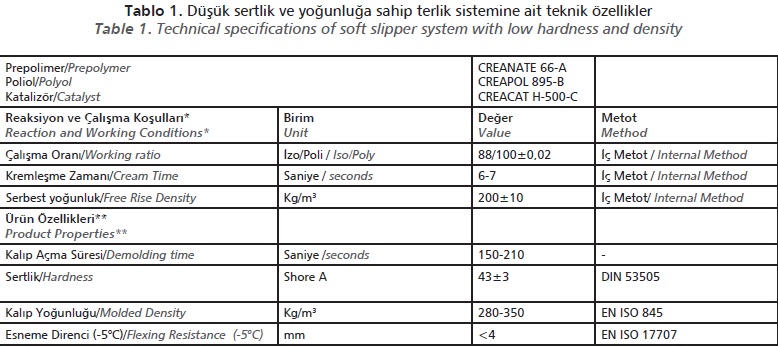

The reaction conditions and mechanical properties of the slipper samples that produced using low pressure machine were examined and the results obtained are given in Table 2.

Flokser Chemical is leading the industry by understanding the needs of the manufacturers with its wide range of products. One of the most important requirements in recent times is the development of slipper systems which have the same properties but can be applied at lower molding densities.

We are introducing an ultra-lightweight slippers system to satisfy the user’s interest in ergonomics and to enable the manufacturer to produce slippers with the same features but less weight.

The reaction conditions and mechanical properties of the slipper samples that produced using low pressure machine were examined and the results obtained are given in Table 2.

Ultra-Lightweight PU Slipper system provides application possibility at 200kg/m3 mold density while keeping lightness at the forefront and providing safe usage with its superior dimensional stability. Compared to the standard slipper products available in the industry, it offers a 35% weight advantage in different mold models.

Ultra-Lightweight PU Slipper system provides application possibility at 200kg/m3 mold density while keeping lightness at the forefront and providing safe usage with its superior dimensional stability. Compared to the standard slipper products available in the industry, it offers a 35% weight advantage in different mold models.

Figure 2. Image of double density safety shoes

Component properties, reaction conditions and mechanical properties of the new polyurethane system with the mentioned advantages are examined and the results are given in Table 3.

With our new polyurethane system developed in Flokser Chemical R&D Center, double density safety shoe system which can be used in midsole and outsole applications has been added to the market.

* Reaction and working conditions were obtained as a result of measurements made with a low-pressure casting machine operating at 6000rpm.

** According to TS EN 12222 standard for 24 hours at 23±2 temperature and P relative humidity, the test results of the samples are given.

Kübra Sarper - Ar-Ge Uzmanı - R&D Specialist - Flokser Kimya

Kerim Can Ünlü - Ar-Ge Uzmanı - R&D Specialist - Flokser Kimya

With our new polyurethane system developed in Flokser Chemical R&D Center, double density safety shoe system which can be used in midsole and outsole applications has been added to the market.

* Reaction and working conditions were obtained as a result of measurements made with a low-pressure casting machine operating at 6000rpm.

** According to TS EN 12222 standard for 24 hours at 23±2 temperature and P relative humidity, the test results of the samples are given.

Kübra Sarper - Ar-Ge Uzmanı - R&D Specialist - Flokser Kimya

Kerim Can Ünlü - Ar-Ge Uzmanı - R&D Specialist - Flokser Kimya