Biobased coatings usage is becoming more common worldwide. Discussion about biobased coatings with Mr. Younes Khermane from Alberdingk Boley shows that there is an increasing demand for UV-Stable polyols based on renewable resources.

Alberdingk Boley is expanding its product range based on renewable resources. The company has a 193 years’ experience of processing vegetable oils and commit to produce sustainable ole chemicals with superior properties under 100% PU polyols product range.

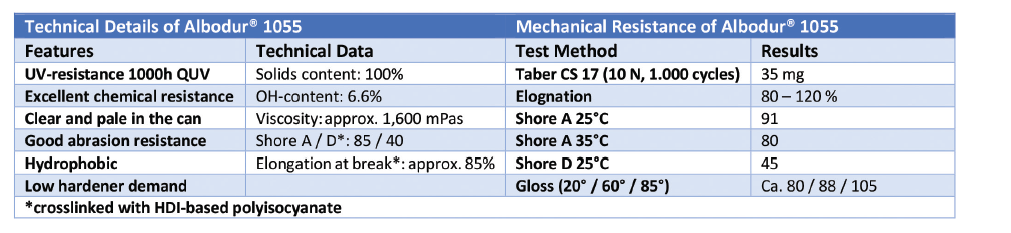

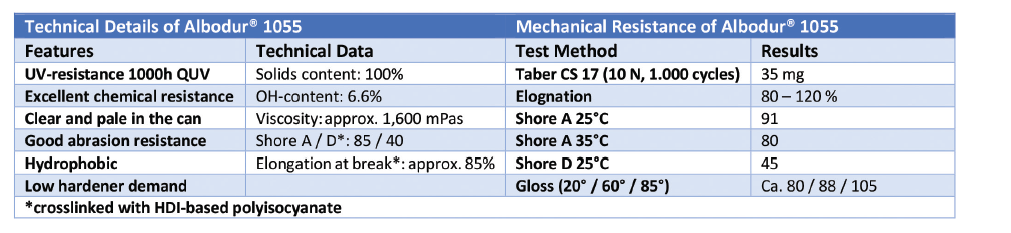

The floor coating market’s demands is getting more complex than pure protection. The new requirements can be sorted as an aesthetic appearance, high durability and light fastness and fire-resistibility. Alberdingk Boley has developed Albodur® 1055, which is UV-stable and based on castor oil, to compensate the market requirements.

Why is the Castor Oil the Perfect Base for Polyols?

Castor oils are the only OH-functional natural oils which can be used in polyurethane systems. The oil characteristics offer a natural hydrophobicity to polyurethane systems and support isolation properties as well as fire resistance. Unlike other oils, the viscosity of castor oil is strongly dependent on temperature.

The lowest viscosity can be achieved at 40°C. Castor oil is ideally delivered between 30°C and 40°C to provide easy handling, low energy consumption on pumping, high pigment loading etc. Alberdingk Boley offers various kinds of castor oil derivatives and polyols based on castor oil.

Floor Coatings: Changing Requirements by Time

In the past, floor coating has mainly been used in industrial areas due to their high chemical, physical and mechanical resistance.

Nowadays, usage of floor coatings in residential areas is getting increase for decorative and specific purposes, such as hygienic demand in hospital, easy to clean property for school and in areas where food contact is important.

Especially; PU floor coating demand is increasing, where weather resistant, durability, UV protection and excellent optical properties required areas like sun decks of cruise ship.

Castor oil-based polyols have long been approved in polymer floorings as a UV-stable and impact-resistance alternative to epoxy systems. They can be used as primers and self-levelling topcoats. 100% polyol-based primers are used particularly on damp concrete or oily concretes.

Floor Coating Structure Floor systems always have a multi-layer build-up. The primer layer seals dust on the concrete and provide adhesion to the following layers. It is followed by a balancing or levelling layer/mortar which fills up pours and has 1mm film thickness. Then, the most important layer which is called self-levelling coating is being applied.

Areas with high foot or machine traffic will also need a topcoat which is mainly solvent or water based and can be reworked with a polish.

Aesthetic, UV Stable Easy to Formulate: Albodur®1055

The polyol offers a hydrophobic property and an extremely pale appearance as neat resin. Besides, when the product is combined with low viscosity isocyanate provide same properties. The polymer structure of Albodur® 1055 allows to reduce requirement of isocyanate in the total system without losing basic features such as good workability, broad versatility and compatibility profile as well as mechanical properties.

Albodur® 1055 is VOC-Free polyol and provides excellent UV-stability beyond the current limits of decorative 2K PU coating systems. PU system light stability can be obtained more than 1000 h QUV A exposure test result with an aliphatic isocyanate crosslinked Albodur ® 1055. Besides, it provides absolutely crystalclear appearance for decorative coatings.

In summary, compared to alternative technologies, this polyol offers a unique performance profile in the formulation of light-stable VOC-free 2K PU coatings.

Albodur®1055 is a UV-stable polyol based on pharmaceutical castor oil that is manufactured at the production site in Krefeld, Germany. It has a guaranteed 65% content of renewable raw material. This environmentally friendly innovation is comparable to pure synthetic systems made from petroleum derivatives.

How Does Albodur® 1055 React with Isocyanate?

Due to the aliphatic technology, the impact of the isocyanate and the catalyst is as strong as the impact of the polyol. The best catalysing effect was observed with DOTL types, especially Dioctyltincarboxylate. Blending time and methods are very important for aliphatic polyols and isocyanate because polyol/isocyanate reaction is very slow compared to isocyanate/ water reaction. Consequently, the more isocyanate usage can boost tendency of reaction with moisture. General applications are floorings (MDIbased), coatings (HDI-based), elastomers/sealants, corrosion protection, and one- and two-pack adhesives.

References

[1] Alberdingk Boley Technology Information – Albodur® Castor oil based polyols

[2] Alberdingk Boley Product Information – Albodur® 1055

[3] PU Magazine – VOL. 16, NO. 5 – October/November 2019

Younes Khermane

Younes Khermane

Chemist

Technical Marketing Dispersions

Alberdingk Boley GmbH

Beyhan Dayıbaş

MSc Chemical Engineer

Technical Sales Specialist

Ravago Chemicals Turkey Kimyasal Hammaddeler Satış ve Pazarlama A.Ş.

Castor oil-based polyols have long been approved in polymer floorings as a UV-stable and impact-resistance alternative to epoxy systems. They can be used as primers and self-levelling topcoats. 100% polyol-based primers are used particularly on damp concrete or oily concretes.

Floor Coating Structure Floor systems always have a multi-layer build-up. The primer layer seals dust on the concrete and provide adhesion to the following layers. It is followed by a balancing or levelling layer/mortar which fills up pours and has 1mm film thickness. Then, the most important layer which is called self-levelling coating is being applied.

Castor oil-based polyols have long been approved in polymer floorings as a UV-stable and impact-resistance alternative to epoxy systems. They can be used as primers and self-levelling topcoats. 100% polyol-based primers are used particularly on damp concrete or oily concretes.

Floor Coating Structure Floor systems always have a multi-layer build-up. The primer layer seals dust on the concrete and provide adhesion to the following layers. It is followed by a balancing or levelling layer/mortar which fills up pours and has 1mm film thickness. Then, the most important layer which is called self-levelling coating is being applied.

Areas with high foot or machine traffic will also need a topcoat which is mainly solvent or water based and can be reworked with a polish.

Areas with high foot or machine traffic will also need a topcoat which is mainly solvent or water based and can be reworked with a polish.

In summary, compared to alternative technologies, this polyol offers a unique performance profile in the formulation of light-stable VOC-free 2K PU coatings.

Albodur®1055 is a UV-stable polyol based on pharmaceutical castor oil that is manufactured at the production site in Krefeld, Germany. It has a guaranteed 65% content of renewable raw material. This environmentally friendly innovation is comparable to pure synthetic systems made from petroleum derivatives.

In summary, compared to alternative technologies, this polyol offers a unique performance profile in the formulation of light-stable VOC-free 2K PU coatings.

Albodur®1055 is a UV-stable polyol based on pharmaceutical castor oil that is manufactured at the production site in Krefeld, Germany. It has a guaranteed 65% content of renewable raw material. This environmentally friendly innovation is comparable to pure synthetic systems made from petroleum derivatives.

Younes Khermane

Chemist

Technical Marketing Dispersions

Alberdingk Boley GmbH

Beyhan Dayıbaş

MSc Chemical Engineer

Technical Sales Specialist

Ravago Chemicals Turkey Kimyasal Hammaddeler Satış ve Pazarlama A.Ş.

Younes Khermane

Chemist

Technical Marketing Dispersions

Alberdingk Boley GmbH

Beyhan Dayıbaş

MSc Chemical Engineer

Technical Sales Specialist

Ravago Chemicals Turkey Kimyasal Hammaddeler Satış ve Pazarlama A.Ş.