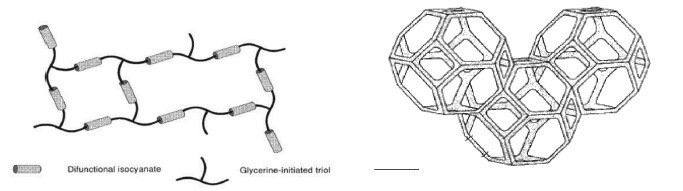

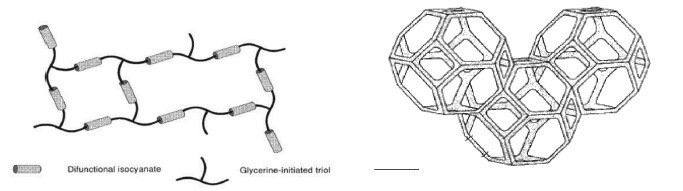

Flexible polyurethane (PUR) foams are open-cell, chemically or physically foamed copolymers formed by diisocyanates containing two or more -NCO groups and polyols containing two or more –OH groups interconnected with urethane-urea groups.

[1] The synthesis of flexible (PUR) foams was first performed in the laboratory in 1941 and its mass production started in 1954 in Germany. Aromatic isocyanates (TDI&MDI) and polyester polyols were used in the production of the first flexible PUR foam.

However, due to the low resistance of synthesized foams to temperature and humidity conditions, problems such as hydrolysis have often been encountered. In 1957, polyether polyols began to be used, which resulted in higher-performance foams.

The use of polyether polyol allowed foams to have higher hydrolysis resistance, more comfortable structure and longer life.

In 1958, the use of new generation catalysts and surfaceactive agents in combination with polyether polyols allowed discontinuous production of flexible PUR foams and greatly improved their mechanical properties.

[2] These developments led to the emergence of “high-resilient” (HR)

(i.e. self-recovering) PUR foams.

Figure 1. Index values in flexible polyurethane (PUR) foam

The comfort, ergonomics and other functions ensured by HR PUR foams due to their high mechanical properties, caused them to be unrivaled and widely used in many applications.

Figure 2. Areas of use of flexible PUR foams [2]

There are basically two reactions in PUR foam synthesis:

1- Blowing Reaction

Figure 3. Chemical representation of blowing reaction [2]

CO

2(g) and urea structures emerge by the blowing reaction. CO

2(g) allows foams to blow up, whereas urea structures ensure them to have mechanical properties. [2]

Figure 4. Representation of urea structures [2]

2- Polymerization Reaction

Figure 5. Chemical representation of polymerization reaction [2]

The polymerization reaction originates urethane groups and ensures the foam to possess its original character.

Figure 6. Two- and three-dimensional representations of flexible polyurethane foam structure [2]

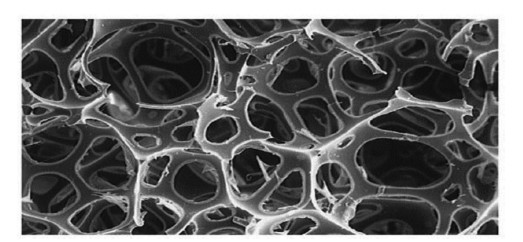

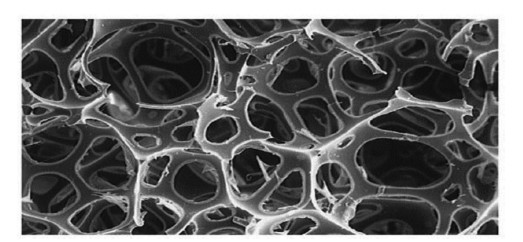

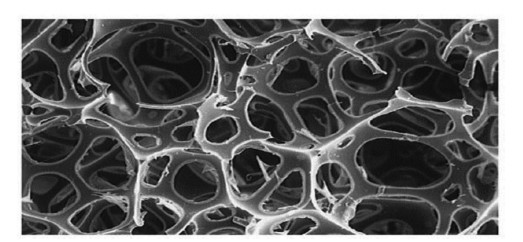

Figure 7. Microscopic view of HR PUR foam structure [2]

The blowing reaction starts before the polymerization reaction but proceeds simultaneously. The rate of these two reactions is very critical in order to achieve a successful foam with the desired properties. If the rate of these two reactions is not adjusted correctly, problems such as shrinkage and collapse are encountered. [2]

Figure 8. Graph of polymer module based on time [2]

The low permanent deformation high elongation percentage and tensile strength values along with high tear resistance in HR PUR foams have made them one of the most comfortable, ergonomic and durable products.

Figure 9. An automobile seat with HR PUR foam [3]

As the Kimteks Polyurethane family, we improve our R&D activities day by day in order to achieve innovative, economical and environmentally friendly products. Our company’s MDI-based, two-component KIMflex FC – Izokim FC HR PUR foam systems offer excellent solutions for the market.

Our products are used in automotive seats and components, office seats, sound insulation and medical products. We design tailor-made products that fulfill all the requirements and needs for a specific market and region as well as the requirements of the relevant certificates.

In this context, for example, we design low temperature resistance pre-polymer systems for regions with harsh climatic conditions, or non-phase-separating polyol mixtures for the customers with no mixer. On the other hand, the certification of products has become a substantial fact at the present time.

In this context, all of our products, especially those used in the automotive industry, have been certified in accordance with the product specifications. The certificates awarded to our products are as follows:

Table 1. The certificates awarded to KIMflex FC – Izokim FC systems used in the automotive industry [4,5]

The last member of the Kimteks Polyurethane HR PUR foam group, KIMflex FC 046 – Izokim FC 015 system with a wide range of operating range (P/I, 100/55 – 100/75), fast curing characteristic, high mechanical and flowability properties, ability to operate trouble-free in demanding process conditions, shiny skin and extraordinary feeling has recently introduced to the market.

This system, thanks to its wide range of operating range, ensures the required hardness and permanent deformation values, which is very critical for office chairs, automotive seats and medical products.

Table 2. Reaction profile analysis and physical characterization of Kimteks Polyurethane KIMflex FC 046 -Izokim FC 015 system foams

Ümit Ünal

R&D Responsible

Flexible&Case

Kimteks Poliüretan San. ve Tic. A.Ş.

References

Ümit Ünal

R&D Responsible

Flexible&Case

Kimteks Poliüretan San. ve Tic. A.Ş.

References

[1] D.K. Chattopadhyay, Dean C. Webster, Thermal stability and flame retardancy of polyurethanes, Progress in Polymer Science, Volume 34, Issue 10, October 2009, Pages 1068-1133

[2] Ron Herrington, Kathy Hock vd., Flexible Polyurethane Foams (The Dow Chemical Company,1997)

[3] http://www.atssynthetic.com.pk/products/chemical-division/pakthane-polyurethane/polyurethane-automotive-industry/

[4] http://gcs-lab.com/tr/flammability_tests.html

[5] http://www.sercovam.com/liste-essai.html#Renault D423109

Ümit Ünal

R&D Responsible

Flexible&Case

Kimteks Poliüretan San. ve Tic. A.Ş.

References

[1] D.K. Chattopadhyay, Dean C. Webster, Thermal stability and flame retardancy of polyurethanes, Progress in Polymer Science, Volume 34, Issue 10, October 2009, Pages 1068-1133

[2] Ron Herrington, Kathy Hock vd., Flexible Polyurethane Foams (The Dow Chemical Company,1997)

[3] http://www.atssynthetic.com.pk/products/chemical-division/pakthane-polyurethane/polyurethane-automotive-industry/

[4] http://gcs-lab.com/tr/flammability_tests.html

[5] http://www.sercovam.com/liste-essai.html#Renault D423109

Ümit Ünal

R&D Responsible

Flexible&Case

Kimteks Poliüretan San. ve Tic. A.Ş.

References

[1] D.K. Chattopadhyay, Dean C. Webster, Thermal stability and flame retardancy of polyurethanes, Progress in Polymer Science, Volume 34, Issue 10, October 2009, Pages 1068-1133

[2] Ron Herrington, Kathy Hock vd., Flexible Polyurethane Foams (The Dow Chemical Company,1997)

[3] http://www.atssynthetic.com.pk/products/chemical-division/pakthane-polyurethane/polyurethane-automotive-industry/

[4] http://gcs-lab.com/tr/flammability_tests.html

[5] http://www.sercovam.com/liste-essai.html#Renault D423109