Up to 80% Wear Resistance

Black Swan's Graphene Product Increases Abrasion Resistance by As Much As 80% in Thermoplastic Polyurethane

When used as an additive in Thermoplastic Polyurethane, Black Swan Graphene Inc.'s GraphCoreTM001 graphene nanoplatelet material ("Graphcore") improves the composite's abrasion resistance by a factor of between 60% and 80%. ("TPU").

The business had previously announced an already-impressive improvement performance of 45% in TPU with a 1% loading ratio (amount of additive material added to a composite material, relative to the amount of matrix material).

A thermoplastic elastomer known as TPU combines some characteristics of both rubber and plastic. It is durable, abrasion- and oil- and lubricant-resistant, tough, flexible, and long-lasting. TPU is ideally suited for a variety of applications, including in automobiles, sporting goods, textile coatings, and mobile phones, thanks to this special combination of properties.

Simon Marcotte, President and Chief Executive Officer of Black Swan Graphene, commented: "Today's performance results serve as a reminder that graphene could revolutionize the enormous polymer industry.

In addition to improving abrasion resistance, graphene offers meaningful benefits such as weight reduction, cost savings, enhanced precision, improved gas permeability, and increased thermal conductivity, all of which can improve existing markets and pave the way for new applications."

The manufacture of the composites, being the Graphcore-enhanced TPU, and the subsequent testing, were carried out independently at the Graphene Engineering Innovation Centre ("GEIC") located at the University of Manchester, United Kingdom.

The precise type of TPU selected for the trials is currently used in mobile equipment and extruded sheets, which are generally used in many industries from packaging to transportation and construction materials. The composites were manufactured via a masterbatch and then moulded to carry out the tests, which were based on loading ratios of 0.5%, 1.0%, and 1.5%.

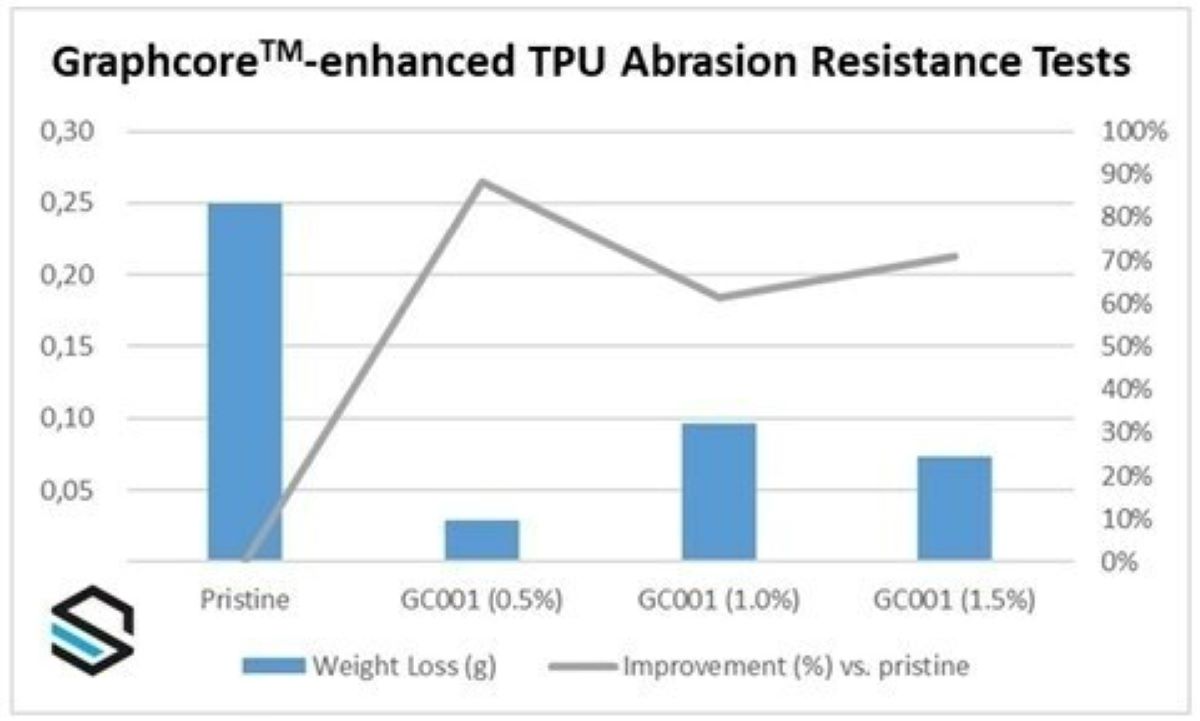

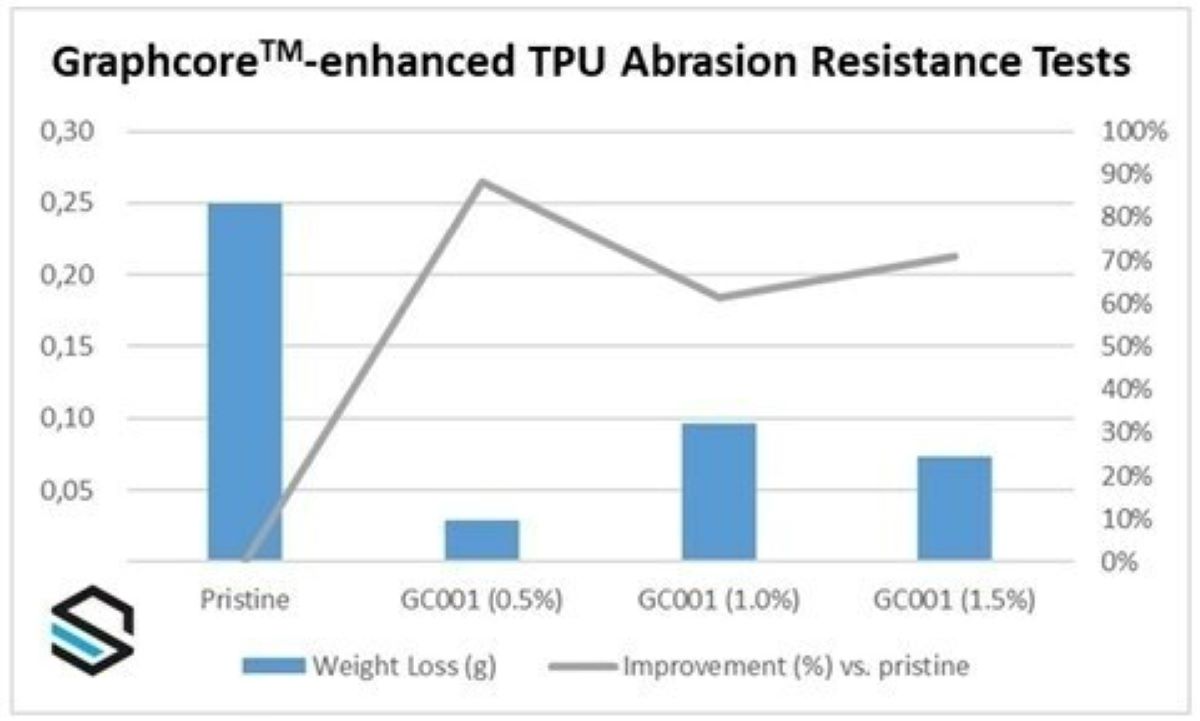

The results, presented in the figure-1 below, show that all the Graphcore-loaded composites demonstrated improvements in performance compared to the pristine level.

Figure 1:

Figure 1: Weight loss and abrasion resistance of TPU composites at different loading levels (CNW Group/Black Swan Graphene Inc)

The abrasion tests correspond to norm ISO 5470 - 1:2016 – Taber abrasion1. Three thousand (3,000) cycles were carried out using standard abrasive wheels with 1,000 grams of weight per wheel. The weight loss was recorded after each 1,000 cycles. Between each 1,000 cycles, the wheels were abraded with the standard sandpaper to 50 cycles; sandpaper was changed for the start of each new test.

Market perspectives

The current plastic additive market (and not the plastic market itself) is estimated to be approximately USD $40 billion per year2. In its 2021 report3, The Graphene Council estimated that the potential annual graphene requirements, when combining all different types of polymers at a 5% loading ratio, would be 12.5 million tons of graphene.

1 This norm complies with the following ISO sustainability targets: Goal 9: Industry, Innovation, and Infrastructure: Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation - Goal 12: Responsible Consumption and Production: Ensure sustainable consumption and production patterns.

2 https://www.emergenresearch.com/industry-report/plastic-additives-market

3 https://www.thegraphenecouncil.org/page/TheGrapheneReport

Note: Content may be edited for style and length

Source

Figure 1: Weight loss and abrasion resistance of TPU composites at different loading levels (CNW Group/Black Swan Graphene Inc)

The abrasion tests correspond to norm ISO 5470 - 1:2016 – Taber abrasion1. Three thousand (3,000) cycles were carried out using standard abrasive wheels with 1,000 grams of weight per wheel. The weight loss was recorded after each 1,000 cycles. Between each 1,000 cycles, the wheels were abraded with the standard sandpaper to 50 cycles; sandpaper was changed for the start of each new test.

Figure 1: Weight loss and abrasion resistance of TPU composites at different loading levels (CNW Group/Black Swan Graphene Inc)

The abrasion tests correspond to norm ISO 5470 - 1:2016 – Taber abrasion1. Three thousand (3,000) cycles were carried out using standard abrasive wheels with 1,000 grams of weight per wheel. The weight loss was recorded after each 1,000 cycles. Between each 1,000 cycles, the wheels were abraded with the standard sandpaper to 50 cycles; sandpaper was changed for the start of each new test.