Natural fats and fatty acids which are produced from vegetables by chemical reactions recently have been started to use at MWF applications.

They are especially preferred for their higher lubrication capability due to their ester form in comparison to conventionel mineral oils, better performance at high enviromental temperatures, lower volatility and almost 100% dissolvement in the nature.

Esters have much better viscosity indexes than conventionel mineral oils (Less viscosity fall due to temperature) and they have better oxidation stability and longer usage time as well.

In comparison to paraffinic based oils, ester forms have much better lubrication capabilities, EP and AW properties. Evaporation loss is also mush less than mineral oils. For this reason esters decrease corrosion&abbrasion rates and they have longer shelf life.

Today, many esters with different formations and properties are produced. In addition to esters with very low viscosities, esters like TMP-TO are also preferred at industrial applications of compressor oil, chain oil and most known waterproof hydrolic oils Etc. as well.

Thanks to their pour point under -50°C and high flash point of 350°C, they are used at all kind of industrial applications and processes requiring lubrication.

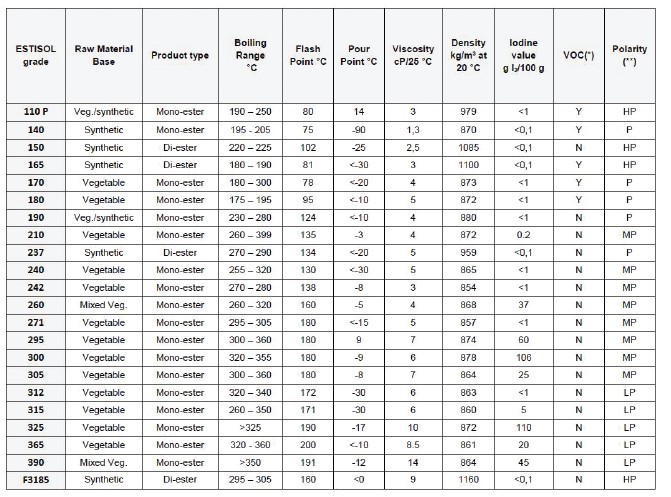

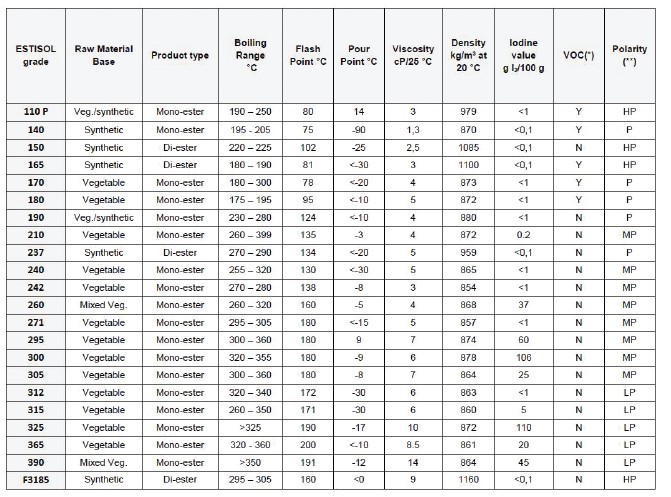

Vegetable Esters and Vegetable Ester Solvents

Today, the usage of vegetable based Solvents&Esters are started at very different MWF and industrial applications. The basic reason of this sitaution is the vegetable form of the product although its solvent nature, with high flash point, enviromental friendly-high levels of decomposition rates.

They have no toxical or hazardous properties which must be mentioned on their safety datasheets. Also, since the products are not suitable to use in fuels like conventionel solvents, they are not subject to any special permit or special consumption tax.

Estichem Vegetable Based Solvent Esters

Estisol 300, a vegetable based Solvent Ester Product, EstiClean AR-Plus, a special mixture of Esters and cleaners which is able to remove all organic impurities and asphalt.

Sulfurised and Polimeric Esters (AW and EP Additives)

Esters are produced by chemical reactions from vegetable fatty oils and acids or their olefins. These chemical reactions are achieved at highly developed reactors under high pressure, temperature and vacuum control.

The EPOIL range of Suphurised Extreme Pressure (EP) additives manufactured by Hornett Bros and Co Ltd are a complex reaction of esters and sulphur, the ester part providing metal wetting and lubricity properties and the sulphur providing EP properties.

Sulphur containing EP additives chemically react with the metal surfaces at elevated temperatures caused by friction under high loads to produce new compounds that acts as a barrier to reduce friction, wear and the possibility of welding.

Hornett Sulfurised Esters (EP and AW Additives)

OCP (Olefin Co-Polimer) and Synhetic Steran Polymer Technologies

OCP and steran based polymers are used to increase the viscosity of oils and to make them multi-grade (such as 5W-30 and 15W40 engine oils).

In our day, polymers with different forms and properties are used.OCP (Olefin Co-polymer) and Stadien-Butadien Rubber, PAMA (Poly –Methyl –Methy – Acrylate) are the most preferred polymer kinds.

In application of these polymers at engine oils, the property which is known as SSI (Shear Stability Index) should be remarked.SSI shows the structural deformation and the loss of the polymers after they are used at test engines. Smaller SSI numbers mean more synthetic polymers which also mean less structural deformation.

Currently, the most preferred polymers at engine oil production are OCP polymers with low ISS number and easy melting feature like 20 ~ 22 SSI Viscotech 6540.For synthetic DPF engine oils, the most preferred product is with 0 ~ 5 SSI Viscotech 494-L Starn Polymer.

PPD (Poly-methyl acrylate) and PAMA (Poly-methyl-methylacrylate)

With their most common name “PPDs” are the synthetic polymers which are used as pour point deppressant of lubricant oils. Thanks to their PM (poly-methylacrilate) polymer forms, showing elasticity property, they delay the freezing of the oil at low temperatures and takes the viscosity to optimum levels.

As for PAMA products, due to their unique polimeric structure (poly-methyl-methylacrilate), although showing PPD properties, they are heavy molecule polymers. Their main usage target is to increase the viscosity index.

They increase the viscosity index as well as they increase the viscosity of the lubricants (Another saying, they prevent the viscosity of the lubricants to fall and change with the temperature).

As special polymer products of Additiv Chemie Luers, Kusapour 300 (PPD) and Kusacryl 840 (PAMA) increase the VI of the lubricants by decreasing the pour points although their very low usage rates ((%0,1 ~ 0,3).

,

Ümit Özvardar

Sales Manager

Troychem DMCC

Ümit Özvardar

Sales Manager

Troychem DMCC

In comparison to paraffinic based oils, ester forms have much better lubrication capabilities, EP and AW properties. Evaporation loss is also mush less than mineral oils. For this reason esters decrease corrosion&abbrasion rates and they have longer shelf life.

In comparison to paraffinic based oils, ester forms have much better lubrication capabilities, EP and AW properties. Evaporation loss is also mush less than mineral oils. For this reason esters decrease corrosion&abbrasion rates and they have longer shelf life. Today, many esters with different formations and properties are produced. In addition to esters with very low viscosities, esters like TMP-TO are also preferred at industrial applications of compressor oil, chain oil and most known waterproof hydrolic oils Etc. as well.

Thanks to their pour point under -50°C and high flash point of 350°C, they are used at all kind of industrial applications and processes requiring lubrication.

Today, many esters with different formations and properties are produced. In addition to esters with very low viscosities, esters like TMP-TO are also preferred at industrial applications of compressor oil, chain oil and most known waterproof hydrolic oils Etc. as well.

Thanks to their pour point under -50°C and high flash point of 350°C, they are used at all kind of industrial applications and processes requiring lubrication.

,

,

Ümit Özvardar

Sales Manager

Troychem DMCC

Ümit Özvardar

Sales Manager

Troychem DMCC