1. Introduction

Since the beginning of the 21st century, agricultural production has been forced to reshape itself under increasing environmental, economic, and social pressures. Rising temperatures, irregular precipitation patterns, increased evaporation rates, and increased drought frequency due to global climate change pose serious threats, particularly to the agricultural sector. Furthermore, overproduction to meet the food demands of a growing population, the inefficiency of traditional irrigation methods, the expansion of agricultural land, and the indiscriminate use of water have increased the pressure on existing water resources to critical levels. With the depletion of water resources, the implementation of innovative, water-efficient, yield-enhancing, and environmentally friendly solutions has become essential to maintain sustainable agricultural production [1,2].

Improper irrigation and water scarcity are among the main factors threatening the sustainability of agriculture, both economically and ecologically. In countries located in semiarid climate zones like Turkey, approximately 70–75% of total water consumption is used in agriculture, and the majority of this is achieved through primitive methods such as surface irrigation [3]. These methods not only cause a significant portion of water to be lost through evaporation or infiltration, but also increase soil salinity, reduce crop yields, and deteriorate soil structure. Over-irrigation also creates anaerobic conditions in the plant root zone, leading to physiological disorders such as root rot. In contrast, dry farming or low-water-input agricultural models require the development of drought-tolerant plant varieties, improved water management, and the integration of innovative material technologies into agriculture. Improper irrigation and the resulting problems are illustrated in Figure 1.1 [1,2].

Figure 1.1 Improper irrigation and resulting problems [1,2]

In this context, nanotechnology and composite materials have a transformative role in the development of sustainable and resilient agricultural systems. Composites developed using nanoengineering techniques, in particular, Membrane systems offer multifaceted benefits such as efficient water management, optimization of plant -microenvironment interactions, reduction of water requirements for seed germination, and minimization of chemical input use. These membranes , produced with functional polymers and nanoscale additives , protect the seed from environmental stress factors and support seed germination and early development processes by passively collecting moisture from the air. Numerous studies are available in the literature on the use of biodegradable polymers such as polylactic acid (PLA), polyvinyl alcohol (PVA), polyethylene glycol (PEG), chitosan (CTS) and similar polymers in agricultural applications; however, most of these studies remain at laboratory scale, and their wide-field applications and commercialization are limited [4,5].

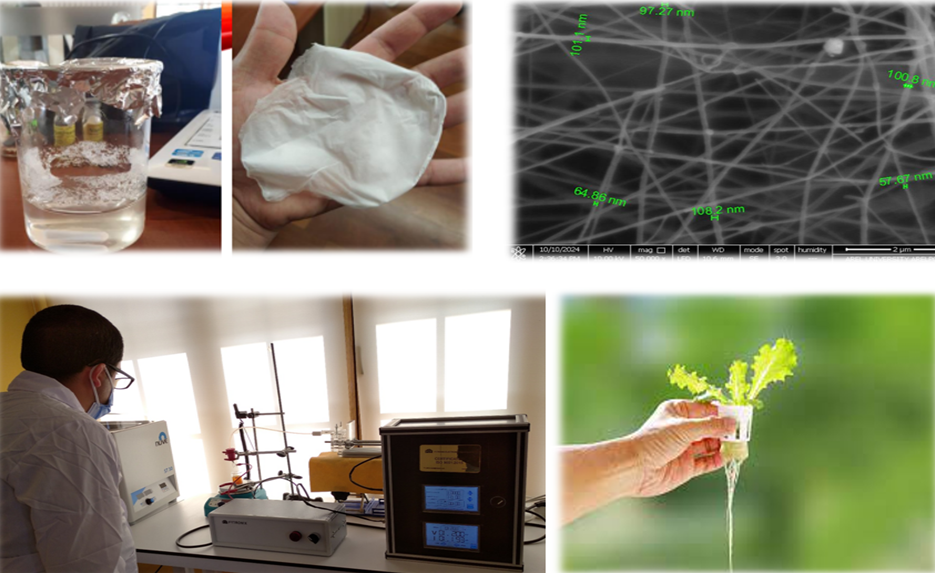

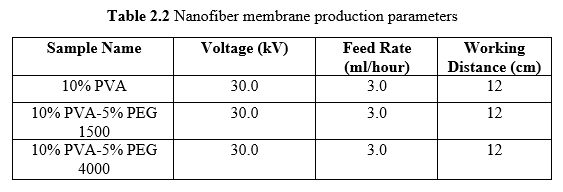

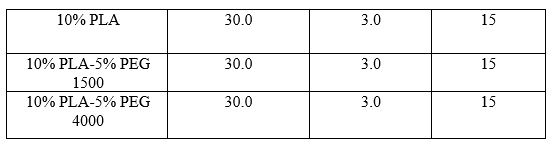

In our research, low-cost and biodegradable nanotechnological materials developed with domestic production competence composite Membrane structures are being considered as a solution that minimizes water use in agriculture, eliminates dependence on chemical pesticides, and optimizes soil utilization. These membranes passively collect moisture directly from the air, particularly during the initial seed germination phase. Their hydrophilic structure allows for controlled moisture release, supporting seed growth without experiencing water stress. This makes dry or minimal water farming practices technically feasible, and an agricultural production model resilient to climate change is being built. This membrane system, applied without direct contact with the soil, also reduces the risk of disease and pests and contributes to environmentally friendly and organic production by eliminating the need for pesticides. Nanotechnology Our electrospinning method and hydroponic agricultural membrane production prototype image is shown in Figure 1.2.

Figure 1.2 Nanotechnology Our electrospinning method and hydroponic agricultural membrane production prototype image

This developed technology not only offers a scientific innovation but also stands out for its high commercialization potential. Its low production costs, ability to produce with domestically sourced raw materials, and the system's portability and scalability make it applicable to both small farmers and large agricultural enterprises. This technology will create economic and environmental benefits, particularly for producers living in rural areas and those conducting their agricultural activities in areas with limited access to water.

This technology's target audience includes farmers interested in sustainable agricultural practices, organic producers, agricultural professionals, academics at universities and research centers, entrepreneurs seeking to invest in environmentally friendly technologies, and public-private organizations focused on green transformation. It also offers a strategically important solution for organizations seeking to improve their environmental performance in line with policies such as the European Green Deal.

In this study, nanotechnology The membranes were obtained in PLA-PEG 1500, PLA-PEG 4000, PVA-PEG 1500, and PVA-PEG 4000 and integrated into our system for use in hydroponic farming applications. The aim is to establish the scientific infrastructure for an agricultural model that is respectful of nature, resilient to the climate crisis, economically viable, and provides social benefits.

2. Materials and Methods

In this study, PLA, PEG 1500, PEG 4000, and PVA were purchased from chemical companies. Pure water was used as the PVA polymer solvent, while dimethylformamide (DMF) and acetone were used as the PLA solvents . In its production, oiled paper was preferred as the base material.

2.1 Preparation of Solutions

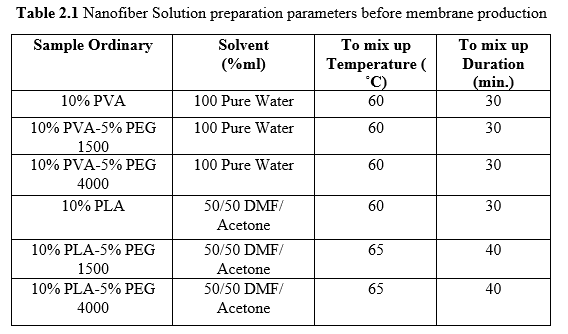

Nanofiber The preparation parameters of the solutions before membrane production are shown in Table 2.1. Due to increased solution viscosity in the 10% PLA-5% PEG 1500 and 10% PLA-5% PEG 4000 samples, the mixing temperature and time were increased. Thus, complete dissolution and homogeneous distribution were achieved.

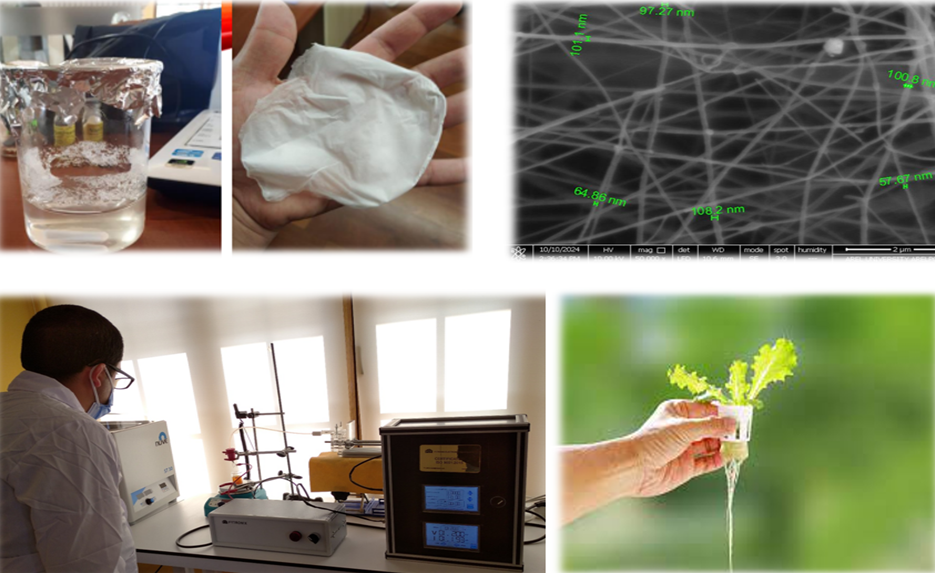

2.2. Obtaining Nanofiber Membranes

Nanofiber membranes: The membrane fabrication process was carried out using our domestically produced electrospinning system. The membrane fabrication process parameters are shown in Table 2.2. The voltage and feed rate parameters were kept constant, while the working distance was varied. Because PLA is a hydrophobic polymer, the working distance was increased to ensure regular fiber formation due to increased viscosity. Other parameter modifications are ongoing as part of our R&D efforts. These modifications are expected to be used in nanofibers. They directly affect membrane morphology and performance. It is a critical element.

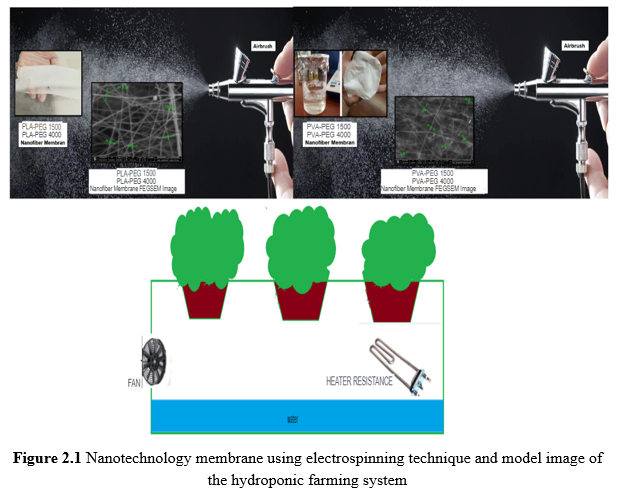

Membranes were obtained by applying the production parameters in Table 2.2. Nanotechnology membrane using electrospinning technique The model image of the hydroponic farming system is shown in Figure 2.1.

2.3. Nanotechnological Hydroponic Agriculture System: Phase Change Membrane -Based Microclimate Application

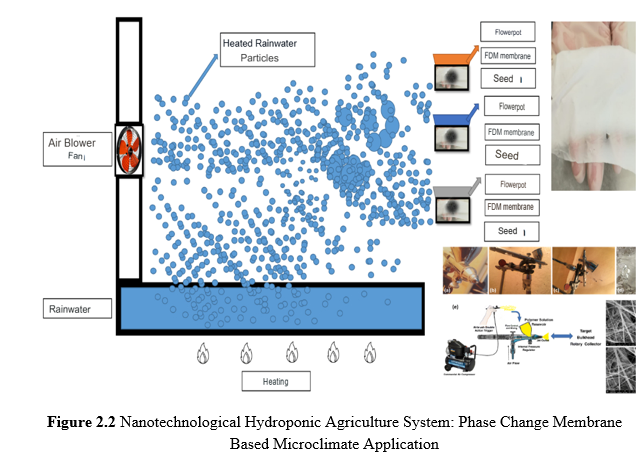

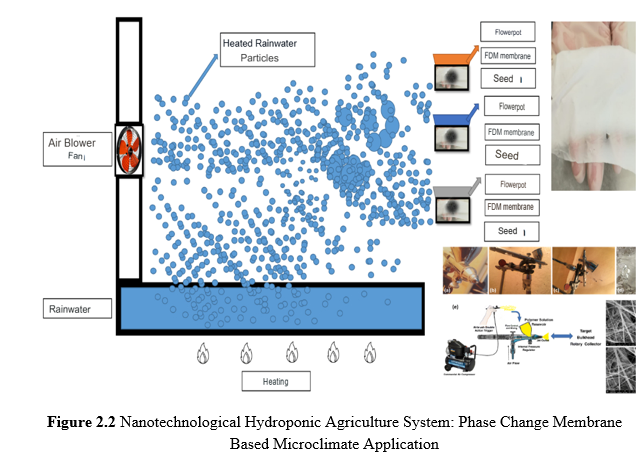

The developed hydroponic farming system allows the cultivation of seeds without the direct need for water resources. It is based on an advanced integrated microclimate management technology that ensures healthy germination and development. The system has a multi-component structure including a rainwater collector reservoir, thermally controlled heating unit, air blower mechanism, porous pots and phase change PCM membranes . In the first stage, rainwater collected from the environment is evaporated in a controlled manner by the heating mechanism in the system; the resulting moisture particles are directed to the porous pots containing seeds via fan-assisted airflow. Special phase change PCM membranes integrated into the inner surface of the pot systems absorb moisture from the environment while also using the temperature difference between day and night as an advantage in energy management. These membranes are made of phase change materials (PCM). Change By being modified with Materials), it can store excess thermal energy coming from the environment during the daytime and release this energy back at night, creating more stable and optimum temperature conditions around the seed. Thanks to this thermal buffering feature, stress factors related to temperature fluctuations are eliminated, and the physiological balance of the seed is maintained throughout the germination process. The structure of the membranes also offers functional characteristics such as high porosity , hydrophilic surface properties and selective permeability , enabling the direct transmission of moisture from the environment to the seed, preventing over-irrigation problems that cause water accumulation in the root zone in the soil. Supported by the phase change mechanism, this moisture management protects the seed against rot, hypoxic conditions or salt accumulation , and eliminates the need for pesticide use. This system is not only a passive transfer mechanism that directs moisture, but also works as an active energy management platform that adapts to environmental temperature changes. Thanks to this integrated system, water waste, heat stress, chemical pollution and low yield, which are the main problems encountered in agriculture, have been effectively prevented; A sustainable, environmentally friendly and highly efficient production model has been implemented. Figure 2.2 shows the Nanotechnological Hydroponic Agriculture System: Phase Change Membrane -Based Microclimate Application.

3. Results and Discussion

This study is about nanotechnology based composite Membrane systems have demonstrated high potential in minimizing water consumption in agriculture, increasing productivity, and adapting to climate change. Nanofibers developed using biodegradable polymers such as PLA, PVA, and PEG The membranes combine the properties of high porosity, hydrophilic-hydrophobic balance, thermal buffering, and controlled moisture release within the same structure. Modified with phase change materials (PCM), these membranes store excess heat during the day and release it at night. By creating a stable microclimate around the seed, they accelerate the germination process and reduce stress factors. Preliminary laboratory data indicate that the system can meet 40–60% of the moisture requirement from atmospheric humidity and increase germination success. The absence of direct contact with the soil has reduced the risk of pathogen transmission and eliminated the need for pesticides. From an industrial perspective, the developed membrane systems offer a viable solution for both small-scale farmers and industrial agricultural enterprises, offering advantages such as low-cost production, use of domestic raw materials, portability, and scalability. They are of strategic value, particularly in regions experiencing water scarcity, the organic agriculture market, and the objectives of environmentally focused policies such as the European Green Deal. Several steps are proposed for the commercialization of the technology. First, PLA-PVA-PEG composite ratios must be optimized for different climates and plant types, and phase-change materials must be adapted to different temperature ranges. Integrating electrospinning systems into high-capacity production lines to produce membranes in roll form, easily transportable, and integratable into different agricultural systems will accelerate the transition to industry. Assessing the potential for use in non-agricultural areas (green roof systems, landscaping, seedling cultivation, post-disaster food production kits) will increase market diversity. Furthermore, return-on-investment analyses that include the economic impacts of water savings, increased yields, and chemical input reduction should be prepared and presented to industrialists. Low carbon footprints should be used as marketing advantages in terms of green investment funds and export incentives. Integration efforts should be undertaken with domestic agricultural machinery manufacturers, and the technology should be brought to the international market by securing funding from programs such as the European Green Deal, IPARD, and Horizon Europe. Consequently, the developed nanotechnology composite The membrane system is positioned as an environmentally friendly, commercially ready innovation that reduces water dependency in agriculture, increases yields, and is ready for commercialization . Its high market demand, low production costs, and policy support present a strong investment opportunity for industrialists both nationally and globally.

References

[1] Kang, J., Ding, R., Wang, S., Tong, L., Chen, J., Lu, H., ... & Kang, S. (2025). Developing high water use efficiency agriculture in China toward food security (Ⅰ): Definition, characteristics, current challenges and advancements. Advances in Agronomy, 190, 275-299.

[2] Pavan, M., Samant, L., Nageshkumar, T., Samreen, S., & Yashaswini, N. G. (2025). Eco-Production of Apparel: Energy-and Water-Efficient Luxury Textiles. In Crafting Sustainability in Luxury Textiles for a Zero-Waste Future (pp. 195-219). Cham: Springer Nature Switzerland.

[3] Acar, B. (2019). Deficit irrigation effect on water use efficiency of crops in arid and semi-arid regions. International Journal of Agriculture and Economic Development, 7(2), 18-25.

[4] Bisht, N., Singh, T., Ansari, M. M., & Chauhan, P. S. (2025). The hidden language of plant-beneficial microbes: Chemo-signaling dynamics in plant microenvironments. World Journal of Microbiology and Biotechnology, 41(2), 35.

[5] Christian, C. E. (2002). Dynamics of a seed dispersal mutualism: costs, benefits, and the consequences of a biological invasion. University of California, Davis.