Fire can lead to the death of people, material losses and loss of unique artistic/historical artifacts. Rapid population growth, skewed urbanization and rapid industrialization increase the number of fires and the amount of damage caused by fires.

One of the measures to be taken to minimize the loss of life and property caused by fires is the use of non-flammable chemicals.

Mainly, these chemicals can be divided into two main groups as flame retardants and smoke suppressing materials such as, additives and reagents. Additives are often used as fillers and do not react with other ingredients unlike reactive ingredients [1].

In general, two important properties are expected from flame retardants. It should have a flame-retardant effect and should not damage the processing properties of the main material to be included later.

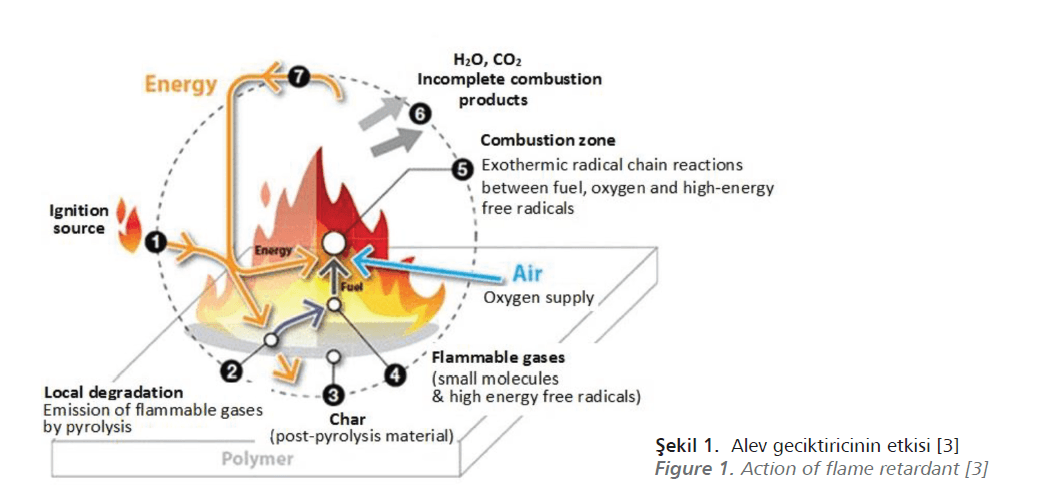

Flame retardant additives, which are added in certain proportions, both dilute the easily flammable main material and reduce the oxygen index of the main substance. Oxygen index is the minimum amount of oxygen required for the main substance to continue burning [2,3].

The market of flame retardants is increasing by 5% annually. The most important reason for this is the increasing use of plastics today. PCB (polychlorinated biphenyls), one of the first flame retardants, was banned in 1977 due to its toxic effect.

Problems related to flame retardants in the world can be listed as the accumulation of inorganic substances in organisms, people being poisoned by these chemicals in case of fire and the effects of unwanted gases caused by combustion on the environment.

The use of materials containing chlorine and bromine-based flame retardants has been periodically restricted or banned after 2000 because of the formation of gases harmful to the environment and human as a result of combustion.

The development of harmless flameretardant polymeric materials has gained great importance in recent years due to the rapid improvement in technology [4].

Flame-retardant polymers can be prepared by adding flame retardant additives to the polymer or attaching the flame-retardant compounds to the polymer by chemical bonds.

The use of flame-retardant additives requires high loading to achieve an adequate level of flame retardancy, and halogenated flame retardants can produce toxic and corrosive fumes during combustion, while chemically bonded compounds can be effective in small amounts.

Compared to halogen-type flame retardants, compounds containing phosphorus during combustion have been found to produce less-toxic gases and fumes. Chemically incorporated phosphorus-containing monomers increase flame retardancy.

Thus, phosphorus containing monomers are widely used in flame retardant coatings. Due to the toxicity and environmental concerns of halogen containing flame retardants, phosphorous containing flame retardants have attracted much attention as environmentally friendly substitutes [5].

Since the flame retardants used as additives collapse over time and their effect decreases, polymers with spontaneous fireproof feature are preferred. Phosphorus- containing flame retardants replace halogenated flame retardants because they produce less toxic gas during combustion [6,7].

Izel Chemical company conducts research on the production of new resins with fire-retardant properties to make more durable coatings.

With chemical bonds, phosphorus containing monomers can be added to different resins such as alkyd, acrylate and polyester, and then the flame-retardancy can be increased in the coatings obtained therefrom.

References

[1] Alexander B. Morgan (2019) The Future of Flame Retardant Polymers – Unmet Needs and Likely New Approaches, Polymer Reviews, 59:1, 25-54.

[2] V. Babrauskas, R. Fuoco, A. Blum, Chapter 3- Flame Retardant Additives in Polymers: When do the Fire Safety Benefits Outweigh the Toxicity Risks? Editor(s): Constantine D. Papaspyrides, Pantelis Kiliaris, Polymer Green Flame Retardants, Elsevier,2014, 87-118.

[3] Al-Mosawi, Ali & Abbas Abdulsada, Shaymaa. (2015). Flame Retardancy of Biopolymer Polyhydroxyalkanoate Composite. International Journal of Advanced Research.3. 883- 886.

[4] Wang, Hui & Wang, Shuang & Du, Xiaosheng & Wang, Haibo & Cheng, Xu & Du, Zongliang. (2019). Synthesis of a novel flame retardant based on DOPO derivatives and its application in waterborne polyurethane. RSC Advances. 9. 7411-7419.

[5 Emrah Çakmakçı, Yusuf Mülazim, Memet Vezir Kahraman, Nilhan Kayaman Apohan, Flame retardant thiol–ene photocured coatings, Reactive and Functional Polymers, Volume 71, Issue 1, 2011, 36-41,

[6] Khalifah A. Salmeia, Sabyasachi Gaan, An overview of some recent advances in DOPOderivatives: Chemistry and flame-retardant applications, Polymer Degradation and Stability, Volume 113, 2015, 119-134.

[7] Shuyu Liang, N. Matthias Neisius, Sabyasachi Gaan, Recent developments in flame retardant polymeric coatings, Progress in Organic Coatings, Volume 76, Issue 11, 2013, 1642-1665.

Dr. Cemil Dızman

Dr. Cemil Dızman

R&D Manager

Izel Chemical

Elif Ozman

R&D Researcher

Izel Chemical

The market of flame retardants is increasing by 5% annually. The most important reason for this is the increasing use of plastics today. PCB (polychlorinated biphenyls), one of the first flame retardants, was banned in 1977 due to its toxic effect.

Problems related to flame retardants in the world can be listed as the accumulation of inorganic substances in organisms, people being poisoned by these chemicals in case of fire and the effects of unwanted gases caused by combustion on the environment.

The use of materials containing chlorine and bromine-based flame retardants has been periodically restricted or banned after 2000 because of the formation of gases harmful to the environment and human as a result of combustion.

The market of flame retardants is increasing by 5% annually. The most important reason for this is the increasing use of plastics today. PCB (polychlorinated biphenyls), one of the first flame retardants, was banned in 1977 due to its toxic effect.

Problems related to flame retardants in the world can be listed as the accumulation of inorganic substances in organisms, people being poisoned by these chemicals in case of fire and the effects of unwanted gases caused by combustion on the environment.

The use of materials containing chlorine and bromine-based flame retardants has been periodically restricted or banned after 2000 because of the formation of gases harmful to the environment and human as a result of combustion.

Dr. Cemil Dızman

R&D Manager

Izel Chemical

Elif Ozman

R&D Researcher

Izel Chemical

Dr. Cemil Dızman

R&D Manager

Izel Chemical

Elif Ozman

R&D Researcher

Izel Chemical