New Generation of Additives for Anti Corrosion From Ascotec

Long Term Corrosion Protection with Asconium®

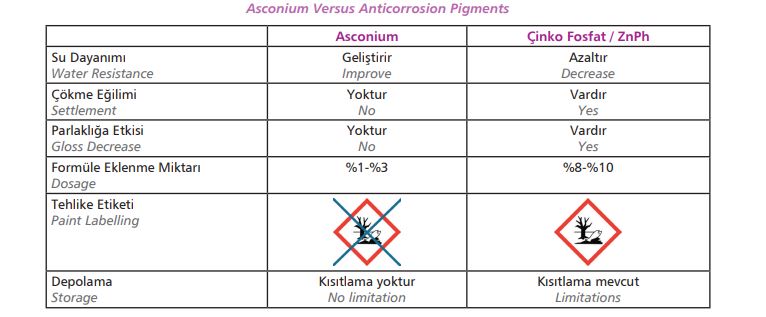

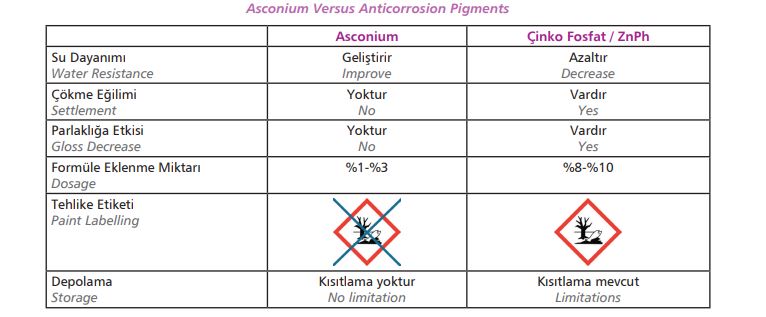

Asconium® with unique proprietary technology are organic liquid-type additives which can provide excellent long-term anticorrosion performance to pigmented or clear coatings. They can be used in those coatings as sole anticorrosion additives or combined with other anticorrosion pigments to improve their performance.

As liquid-type additives, they are easy to incorporate in coating’s formulations and will not cause settling nor reduce the gloss of the coating’s dry fim. They can be used in a wide range of coatings from waterborne to solventborne, for industrial, architectural or DIY systems. With its unique active composition, unlike its competitors, it has more water repellency and offers better corrosion performance.

Key Benefits of Asconium® Technology

• Efficient at low dosage,

• Improving adhesion of coating on metal,

• Improving film’s water resistance,

• Reducing film blistering,

• No settling problem,

• No effect on gloss,

• Outperforming versus conventional anticorrosion pigments,

• Multi metal protection,

• Usable in clear coats.

[caption id="attachment_142778" align="aligncenter" width="709"]

Picture 1: Comparison of Asconium versus conventional anti corrosion additives[/caption]

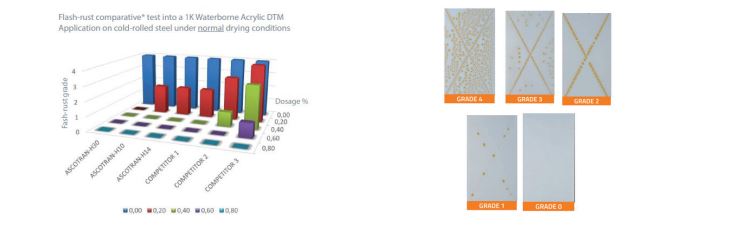

Ascotran® Additives for Flash Rusting

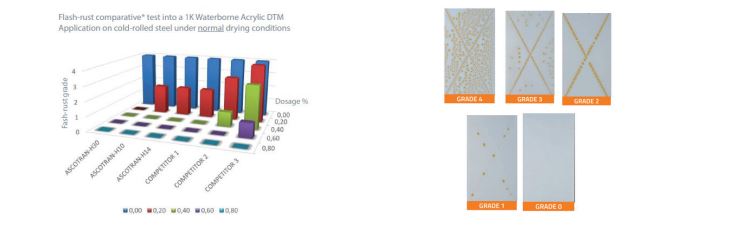

Water borne coatings are widely developed to meet new VOC and regulatory requirements. Everytime a waterborne coating is applied on metal, flash-rust phenomenon, which is immediate corrosion of metal substrates, is of concern. In order to meet this new

demand, Ascotec® has developed a complete range of bio-based flash-rust inhibitors containing biobased substances.

They will be effective in many different situations, whatever the substrate which needs to be protected or the coatings nature will be. Ascotran® additives provide highest levels of flash-rust inhibition, at low use dosages, and then compete with high nitrite-containing additives.

When the film dries under severe humidity conditions, they perform better than most usual flash-rust inhibitors, even on difficult substrates like cast-iron or sand-blasted steel. While usual flash-rust inhibitors reduce waterresistance of coatings, the Ascotran® technology combines excellent antiflash-rust performance with hydrophobic properties.

[caption id="attachment_142780" align="aligncenter" width="729"]

Picture 2: Performance of Ascotran series based on various addition amounts compared to its competitors[/caption]

Ascotran® also provides in-can corrosion protection for water based systems during the storage in metal packaging. These grades have Eco-Label and do not contain VOC.

[caption id="attachment_142781" align="aligncenter" width="601"]

Picture 3: In can corrosion protection-snamples without / with Ascotran[/caption]

Consequently, regardless of requested corrosion category or type of coating, we will be glad to provide you any technical support you may need within Ascotec’s product range.

Bengi Aydilek Beyaz

Sales Manager

Prosim Kimya

Picture 1: Comparison of Asconium versus conventional anti corrosion additives[/caption]

Picture 1: Comparison of Asconium versus conventional anti corrosion additives[/caption]

Picture 2: Performance of Ascotran series based on various addition amounts compared to its competitors[/caption]

Ascotran® also provides in-can corrosion protection for water based systems during the storage in metal packaging. These grades have Eco-Label and do not contain VOC.

[caption id="attachment_142781" align="aligncenter" width="601"]

Picture 2: Performance of Ascotran series based on various addition amounts compared to its competitors[/caption]

Ascotran® also provides in-can corrosion protection for water based systems during the storage in metal packaging. These grades have Eco-Label and do not contain VOC.

[caption id="attachment_142781" align="aligncenter" width="601"] Picture 3: In can corrosion protection-snamples without / with Ascotran[/caption]

Consequently, regardless of requested corrosion category or type of coating, we will be glad to provide you any technical support you may need within Ascotec’s product range.

Bengi Aydilek Beyaz

Sales Manager

Prosim Kimya

Picture 3: In can corrosion protection-snamples without / with Ascotran[/caption]

Consequently, regardless of requested corrosion category or type of coating, we will be glad to provide you any technical support you may need within Ascotec’s product range.

Bengi Aydilek Beyaz

Sales Manager

Prosim Kimya