Figure 1. Kobe Polyurethane Sole System[/caption]

In slipper and sole systems, mechanical tests are carried out to examine the behavior of materials. The most important of these tests are flex resistance and tensile tests. In the developed base system, both the flexing resistance test and the tensile tests are better than standard products.

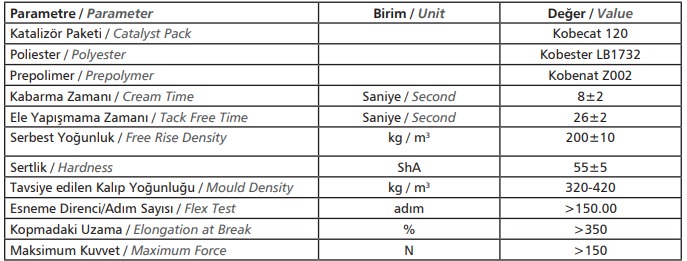

In the Kobecat 120 / Kobester LB1732 / Kobenat Z002 system developed for the sports sole, the test conditions are made more difficult, and the flex feature is more than 150,000

steps at 0°C in the test. In the tensile test, the maximum load carrying capacity and the percent elongation at break were determined.

[caption id="attachment_141527" align="aligncenter" width="300"]

Figure 1. Kobe Polyurethane Sole System[/caption]

In slipper and sole systems, mechanical tests are carried out to examine the behavior of materials. The most important of these tests are flex resistance and tensile tests. In the developed base system, both the flexing resistance test and the tensile tests are better than standard products.

In the Kobecat 120 / Kobester LB1732 / Kobenat Z002 system developed for the sports sole, the test conditions are made more difficult, and the flex feature is more than 150,000

steps at 0°C in the test. In the tensile test, the maximum load carrying capacity and the percent elongation at break were determined.

[caption id="attachment_141527" align="aligncenter" width="300"] Figure 2. Flex Test[/caption]

The work consists of three stages. First of all, laboratory synthesis and application studies are carried out together with the design, in the second step, test castings and their tests with the low pressure machine in the company, and in the last stage, the tests of the

products that come as a result of customer trials and customer serial trials are carried out. The results of these triple confirmation tests are given in the table below.

[caption id="attachment_141531" align="aligncenter" width="687"]

Figure 2. Flex Test[/caption]

The work consists of three stages. First of all, laboratory synthesis and application studies are carried out together with the design, in the second step, test castings and their tests with the low pressure machine in the company, and in the last stage, the tests of the

products that come as a result of customer trials and customer serial trials are carried out. The results of these triple confirmation tests are given in the table below.

[caption id="attachment_141531" align="aligncenter" width="687"] Table 1[/caption]

Table 1[/caption]

Figure 3. Kobe Polyurethane Slipper System[/caption]

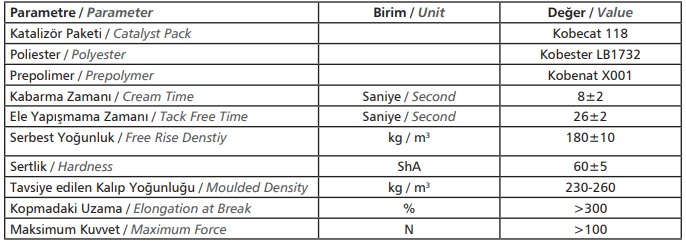

Although the expectation of flexing resistance in slipper systems is low, the developed Kobecat 118 / Kobester LB1732 / Kobenat X001 system has more than 40,000 steps of flex feature. It is observed that these values are between 10,000-30,000 in competitor products tested under the same conditions.

[caption id="attachment_141533" align="aligncenter" width="686"]

Figure 3. Kobe Polyurethane Slipper System[/caption]

Although the expectation of flexing resistance in slipper systems is low, the developed Kobecat 118 / Kobester LB1732 / Kobenat X001 system has more than 40,000 steps of flex feature. It is observed that these values are between 10,000-30,000 in competitor products tested under the same conditions.

[caption id="attachment_141533" align="aligncenter" width="686"] Table 2[/caption]

Gülhan Sarıgöl

R&D Engineer

Kobe Polyurethane

Table 2[/caption]

Gülhan Sarıgöl

R&D Engineer

Kobe Polyurethane