MAYO-MAX takes it further with optimized functionality and reliability

Is it reasonable to claim that egg yolk is nature´s emulsifying champion? Yes absolutely, and in this article, the reasoning and logic behind this bold claim is presented.

Egg yolk is a multifunctional emulsifier with exceptional stability across a wide range of processing conditions, including elevated temperatures and low pH. Its robust emulsifying capacity ensures long-term emulsion integrity, making it a critical component in advanced formulations. Importantly, egg yolk combines high functionality with environmental responsibility. It is a biodegradable and sustainable choice.

In the article you will also be introduced to Källbergs range of egg yolk-based products for mayonnaise and sauces; MAYO-MAX, where the yolk’s emulsifying properties are further enhanced. The emulsifying capabilities are optimized through precise control of manufacturing parameters, enzymatic modifications, tailored yolk-white ratios, and synergistic formulations with starches and hydrocolloids.

Egg Yolk – nature´s emulsifying champion

Egg yolk is widely used in various industries due to its unique emulsifying properties:

• Food Industry: Mayonnaise, hollandaise/bearnaise sauce, dressings, and baked goods all rely on egg yolk for stable emulsions.

• Pharmaceutical & Nutritional Applications: Used in products such as the globally distribute fat emulsion Intralipid – developed in Sweden – for safe, stable lipid delivery in parenteral nutrition. The emulsion is stabilized by phospholipids derived from eggs.

• Cosmetics & Skincare: Egg yolk phospholipids and proteins enhance texture, absorption, and hydration – offering a natural alternative to synthetic surfactants.

This article examines the functional role of egg yolk in food emulsions, emphasizing its effectiveness as a natural emulsifier in complex systems. The emulsifying capacity of egg yolk arises from its diverse biochemical components which adsorb at the oil–water interface, lowering interfacial tension as well as forming a viscoelastic interfacial film.

Before exploring the role of egg yolk and its various components, it is important to define an emulsion – this is a system consisting of two immiscible liquids, typically oil and water, in which one is dispersed as fine droplets within the other. In the absence of emulsifiers, these systems are inherently unstable and tend to separate over time. Emulsifiers function by lowering interfacial tension, thereby promoting droplet formation and enhancing emulsion stability.

Egg constituents comprise a range of emulsifying agents – such as phospholipids, lipoproteins, and proteins – that all play critical roles in modulating the texture, enhancing the physicochemical stability, and improving the overall quality of emulsion-based food systems.

In real-world emulsified systems like mayonnaise, these multiple classes of molecules offer a natural, multi-layered stabilization strategy that is hard to replicate with single-component emulsifiers.

Egg Phospholipids: The powerful emulsifier

Egg phospholipids are located exclusively in the yolk. These small molecules play a central role in the formation and stabilization of emulsions by rapidly adsorbing at the oil–water interface and effectively lowering interfacial tension, thereby facilitating a fast emulsification. (1)

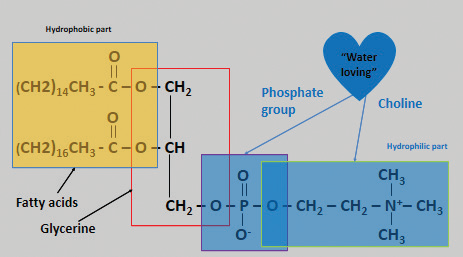

The phospholipids consist of a hydrophilic (water-attracting) head group and one or more hydrophobic (lipid-soluble) fatty acid tails. This structural duality enables them to orient at oil–water interfaces, where they reduce interfacial tension and stabilizes by forming cohesive interfacial films around dispersed droplets.

About 10–12% of egg yolk dry substance are phospholipids. The predominant phospholipid species are phosphatidylcholine (lecithin), accounting for approximately 70–75% of the total phospholipid fraction, followed by phosphatidylethanolamine (15–20%) and minor quantities of phosphatidylinositol and other phospholipids.

Figure 1. Phosphatidylcholine with its hydrophilic and hydrophobic parts.

Egg Lipoproteins: The Hidden Helpers

In addition to phospholipids, egg yolk contains lipoproteins that further enhance its emulsifying ability. Lipoproteins are complexes of lipids and proteins that stabilize emulsions by interacting with both fat and water molecules. Egg yolk contains both low-density (LDL) and high-density lipoproteins (HDL), which both have been demonstrated to enhance emulsion stability. (2)

LDLs are macromolecular assemblies composed primarily of neutral lipids (triglycerides, cholesterol) encased in a surface monolayer of phospholipids and apolipoproteins and play a significant role by reducing coalescence (the merging of oil droplets) by adsorbing at the oil–water interface on the oil droplets. The LDL´s typically measures 17–22 nm in diameter.

HDLs are protein-lipid complexes (~60% protein, ~40% lipids) also adsorbing at oil–water interfaces. Though slower to reduce interfacial tension than phospholipids, they stabilize emulsions by forming thick interfacial layers and providing steric hindrance. The HDL´s typically have a size of 8–12 nm in diameter.

Egg Proteins: The Emulsion Stabilizers

Egg proteins, while slower to adsorb at the oil–water interface than phospholipids, ultimately develop more robust and elastic films that enhance resistance to droplet coalescence. Both egg white and yolk proteins contribute to emulsion stability. Under thermal or pH-induced stress, these proteins can undergo conformational changes, exposing hydrophobic regions and facilitating intermolecular interactions – including hydrophobic forces, electrostatic attractions, and disulfide bond formation. The resulting composite interfacial films significantly improve emulsion resilience to shear, heat, and coalescence during processing.

A study published in Food Hydrocolloids (3) demonstrated that egg white proteins interact with egg yolk phospholipids, reinforcing emulsion strength and reducing droplet size, leading to improved consistency in food formulations.

Under heat or pH stress, egg white proteins also denature and gel, increasing the viscosity of the continuous phase and thereby enhancing emulsion stability by limiting droplet movement and phase separation.

Enzymatic modifications

Enzymatic modification of egg yolk components offers versatile strategies to enhance their functional performance in food systems. By selectively targeting specific molecular constituents, enzymes can tailor key properties such as emulsifying capacity, texture, and oxidative stability. For example, partial hydrolysis of yolk proteins using proteases generates smaller peptides with enhanced surface activity, improving interfacial behavior in emulsions. Similarly, enzymatic hydrolysis of lipids can alter mouthfeel attributes like creaminess and richness. Treatment with transglutaminase promotes protein cross-linking, resulting in firmer, more cohesive textures. Glucose oxidase depletes oxygen from the system, mitigating oxidative degradation and indirectly contributing to improved emulsion stability.

However, this article focuses on the enzymatic modification of egg yolk via phospholipase A2 (PLA2), which considerably enhances its intrinsic emulsifying properties by structurally modifying yolk phospholipids. Several studies have investigated the enzymatic treatment of egg yolk with phospholipase A2 (PLA2), consistently reporting significant improvements in both emulsifying capacity and stability. This is supported by several studies, including (4), (5) and (6).

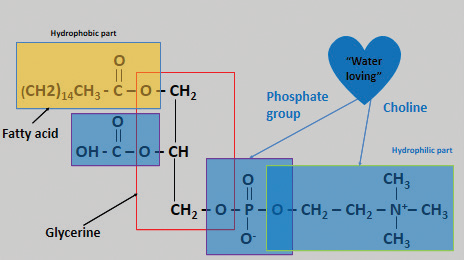

PLA2 is an enzyme that specifically targets and modifies the phospholipids’ unique structure consisting of a hydrophilic (water-attracting) head and a hydrophobic (oil-attracting) tail. PLA2 works by hydrolyzing the sn-2 fatty acid bond in phospholipids like phosphatidylcholine, converting it into lyso-phosphatidylcholine. This change increases the hydrophilicity (water affinity) of the molecule, making it even more effective at stabilizing emulsions.

Figure 2. Lyso-phosphatidylcholine with its increased hydrophilic and decreased hydrophobic parts.

PLA2-modified egg yolk provides:

- Enhanced emulsification power. The modified phospholipids create stronger and more stable emulsions.

- Increased emulsion stability over time. PLA2 modified egg yolk forms emulsions that are more resistant to separation, improving the shelf life.

- PLA2-modified egg yolk retains its emulsifying ability even at high temperatures, making it suitable for “high-heat applications”

Consumers are looking for clean-label products with fewer artificial additives. Because PLA2 is a natural enzyme, its use aligns with the clean-label trend, offering an effective yet natural way to enhance food emulsification without synthetic stabilizers.

The enzymatic modification of egg yolk using PLA2 represents a significant advancement in food science and manufacturing.

Process-induced modifications - protein denaturation

Both egg yolk and white contain numerous proteins that interact with egg phospholipids to enhance emulsification. However, heat-induced denaturation alters their structural properties, impacting their surface activity, solubility, and ability to form stable emulsions (4, 5)

The degree of protein denaturation – whether mild, moderate, or severe – must be controlled.

At temperatures between 40°C and 60°C, proteins undergo partial unfolding, exposing hydrophobic regions. This enhances their interfacial activity, allowing them to adsorb more effectively at the oil-water interface. Emulsion stability improves as proteins interact more efficiently with phospholipids to form a stable layer around oil droplets.

With further heat exposure (60°C–75°C), the effect is mixed. Some proteins aggregate and lose solubility. The emulsifying ability is partially compromised because aggregated proteins are less flexible in coating oil droplets. At high temperatures (above 75°C), proteins become fully denatured and insoluble, leading to precipitation and phase separation. (7, 8)

Temperature is not the sole factor influencing the thermal denaturation of egg proteins; water activity (aw) also plays a critical role and requires careful control. At high aw levels, ample water facilitates protein unfolding during heating. Conversely, low aw restricts molecular mobility and water–protein interactions, thereby impeding denaturation and often enhancing thermal stability.

Optimizing processing temperatures in combination with aw is key to maintaining the functional benefits of egg yolk proteins in emulsions.

Combining egg and hydrocolloids in emulsions

The synergy between eggs and hydrocolloids forms a dual-stabilizing system. While egg phospholipids – supported by other egg components – stabilize the oil-water interface, hydrocolloids such as starch enhance the continuous phase by increasing viscosity and restricting droplet mobility, thereby reinforcing overall emulsion stability.

Formulating low-fat mayonnaise is challenging because reducing oil (from 70–80% to 10–30% fat) weakens emulsion stability. Fewer stabilized droplets lower viscosity, increase separation risk, and diminish creaminess and mouthfeel. To compensate, alternative stabilizers and texture enhancers are needed.

Starches

Starches from various plant sources, such as corn, potato, rice, and tapioca, are used. When incorporated into emulsions, starches absorb water and swell, forming a viscous gel-like structure. This leads to a more robust structure that is less prone to separation, longer shelf-life and greater resistance to environmental stress.

Recent research has highlighted the effectiveness of combining egg yolk and starch in emulsions. A study published in Food Hydrocolloids (9) found that egg yolk-starch combinations improved the viscosity and stability of oil-in-water emulsions, significantly reducing droplet size and enhancing texture. Another study in Journal of Food Science (10) demonstrated that starch-enriched emulsions exhibited greater resistance to heat and shear stress, making them ideal for industrial food processing.

Food gums

Food gums such as xanthan gum, guar gum, locust bean gum, and carrageenan can play an important role in enhancing the stability and texture of emulsions like mayonnaise. These hydrocolloids increase the viscosity of the continuous (water-based) phase, which helps immobilize dispersed oil droplets and forms a gel-like network that retains water.

Combining egg yolk with selected food gums in low-fat mayonnaise formulations yields synergistic effects that help address both structural and sensory limitations associated with reduced oil content. Egg yolk components facilitate emulsion formation and stability, while food gums such as xanthan gum enhance the viscosity of the continuous phase and introduce pseudoplastic flow behavior, resulting in a creamy, spoonable texture that closely mimics full-fat mayonnaise.

A recent review article in Food Science & Nutrition (11) highlighted the role of food gums like xanthan and guar gum in enhancing the viscosity and stability of low-fat mayonnaise. These gums help in mimicking the mouthfeel of traditional mayonnaise by stabilizing the emulsion and preventing phase separation.

Emulsifying starches

Emulsifying starches are modified starches with dual functionality: they contribute to viscosity while also stabilizing oil-in-water emulsions by aiding in droplet dispersion. When used in conjunction with egg yolk, they complement its emulsifying action by enhancing creaminess, improving mouthfeel, and reinforcing emulsion stability.

One notable study in Carbohydrate Polymers (12) investigated the formation of egg yolk–modified starch complexes to stabilize emulsions. The researchers found that combining egg yolk with modified starches, such as octenyl succinic anhydride (OSA), resulted in enhanced emulsion stability. These complexes improved the viscosity of the continuous phase and reduced droplet size, leading to more stable emulsions. Another study (13) focused on the interactions between hydrophobically modified starch and egg yolk proteins in emulsions. The findings demonstrated that the combination of these components could form multilayered interfacial films around oil droplets.

MAYO-MAX - stabilizers for mayonnaise

MAYO-MAX Heat Stable Egg Yolk Powder at YouTube

The MAYO-MAX product range is engineered for excellence in mayonnaise and sauce applications, combining advanced food chemistry with practical production insight. Developed through a deep understanding of egg-based emulsion technology and the functional science behind ingredient interactions.

MAYO-MAX products are designed to meet the real-world needs of manufacturers. Expertise extends beyond the lab – drawing on close collaboration with customers to align with their specific formulations and production processes, ensuring optimal performance, efficiency, and consistency in every batch.

The portfolio includes high-performance egg-based ingredients, mayonnaise mixes, and a range of additive-free egg-based ingredients known as “clean label” products thar are aligned with today’s consumer demand for transparency and natural formulations.

Lower dosage – cost savings

The improved functionality allows for lower dosage, translating directly into cost savings without compromising quality.

Increased heat stability

Engineered for heat stability, it supports robust emulsions that withstand thermal processing –ideal for sauces, dressings, and ready meals. Designed to provide enhanced emulsification, it ensures stable, homogeneous emulsions even under challenging processing conditions.

Powdered - prolonged shelf life

Powdered egg yolk offers a smart, efficient solution for mayonnaise manufacturers seeking quality and convenience. With a significantly longer shelf life than liquid alternatives, it ensures extended usability without compromising on functionality. Its dry, room-temperature storage eliminates the need for refrigeration, reducing both storage and transportation costs.

Customized

Furthermore, MAYO-MAX includes tailored solutions to meet specific customer requirements for taste, texture, and functionality, ensuring the perfect fit for your formulation needs. Customizable packaging allows for customer-specific formats, enhancing operational flexibility. Plus, with minimal spoilage and precise portion control, waste is dramatically reduced, making powdered egg yolk a sustainable and cost-effective choice for modern food production.

References:

1. Anton, M. (2013). Egg yolk: structures, functionalities and processes. In Y. Mine (Ed.), Egg Bioscience and Biotechnology (pp. 1–52). Wiley-Blackwell.

2. Martinet et al. (2003). Emulsifying properties and adsorption behavior of egg yolk lipoproteins (LDL and HDL) in oil-in-water emulsions. Recent Research Developments in Agricultural & Food Chemistry, 37, 103–116.

3. Zhao et al. (2021). Interactions between egg white proteins and egg yolk phospholipids in oil-in-water emulsions: Impact on droplet size and emulsion stability. Food Hydrocolloids, 118, 106753.

4. Daimer et al. (2008). Optimization of the enzymatic modification of egg yolk by phospholipase A₂ to improve its functionality for mayonnaise production. Food Hydrocolloids, 22(3), 436–444.

5. Daimer et al. (2009). Oil-in-water emulsion properties of egg yolk: Effect of enzymatic modification by phospholipase A₂. Food Hydrocolloids, 23(5), 1366–1373.

6. Kato et al. (1998). Impact of a treatment with phospholipase A₂ on the physicochemical properties of egg yolk. Journal of Agricultural and Food Chemistry, 46(10), 3932–3936.

7. Ali et al. (2022). Egg yolk, a multifunctional emulsifier: New insights on factors affecting its emulsifying properties. Applied Sciences, 12(21), 10000.

8. Zhao et al. (2022). Thermal processing of liquid egg yolks modulates physio-chemical properties and emulsion stability. Foods, 11(10), 1426.

9. Zhang et al. (2022). Effects of starch addition on the stability and rheological properties of egg yolk emulsions. Food Hydrocolloids, 123, 107123.

10. Kim et al. (2021). Effects of phospholipase A₂ treatment on the emulsifying properties of egg yolk in mayonnaise. Journal of Food Science, 86(5), 1234–1242.

11. Kadirvel et al. (2023). Edible gums – An extensive review on its diverse applications in food industry. Food & Bioprocess Engineering, 2(1), 1–20.

12. Xu et al. (2020). Formation of egg yolk – modified starch complex and its stabilization effect on high internal phase emulsions. Carbohydrate Polymers, 247, 11672.

13. Magnusson, E. (2009). Interactions between hydrophobically modified starch and egg yolk proteins in solution and at oil/water interfaces (master’s thesis). University of Kalmar, Sweden, School of Pure and Applied Natural Sciences.

Author

Christer Rosén, Ph.D.

Senior Technical Advisor

Danæg Group

Ph.D. in Food Engineering

Lund University