The industry’s demand for sustainable coatings and adhesive solutions has initiated the transition from solvent-based systems to water-based systems in recent years. More than 40 years ago, Witcobond® polyurethane dispersions (PUD) were developed to enable customers to comply with increasingly demanding regulations regarding volatile organic content (VOC) while at the same time developing suitable solutions.

In addition to these, various studies were carried out according to special application

needs in order to develop high-performance and high-solid content products in Witcobond® product development studies.

Today, Witcobond® branded polyurethane dispersions provide diversity, performance,

innovation, and special advantages to users in many different areas.

Advantages of Witcobond® PUD

• Portfolio with a strong performance at high solids grades,

• Water-based blocked crosslinkers for 1K and 2K systems,

• Over 40 years of experience and the ability to customize the application,

• High quality and product consistency.

Formulators of water-based coating systems can choose from a wide variety of Witcobond® polyurethane dispersions. Lanxess offers anionic, nonionic, and cationic grades as well as ester and ether types.

It is possible to offer variations in final coating properties such as hardness, flexibility, toughness, and chemical resistance with Witcobond® products.

Matt Surface Appearance with Witcobond 391-64

Witcobond® polyurethane dispersions can be crosslinked with various agents to further improve chemical resistance, coating adhesion, and durability. Lanxess’s Trixene® Aqua range contains water dispersed latent crosslinkers and adhesion promoters to formulate 1K or 2K furnace systems.

When heated, these multifunctional blocked isocyanates begin to crosslink with complementary functional groups in the coating and substrate.

Main Features

• Solids content ranges from 30% to 60% by weight.

• Offers co-solvent and surfactant-free grades to optimize.

• Meets HS&E requirements.

• Special grades for special coating needs (eg matt surfaces or soft-touch).

• Compatible with a wide variety of aqueous binders such as acrylic dispersions.

• Compatible with pigments, mattifiers, flame retardants, and other auxiliaries.

Witcobond® polyurethane dispersions lead special applications.

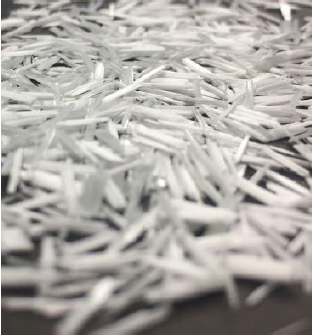

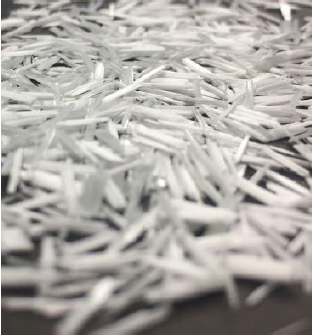

Fiber Sizing and Composites

Lanxess’s polyurethane dispersions are widely used in the fiber sizing industry and can be adapted for new requirements. They provide superior adhesion of filaments in fiber and composite processing and achieve outstanding physical properties in final applications.

Witcobond® 374-13 is a polyester-based polyurethane dispersion commonly used as a film former in glass sizing recipes. It provides excellent integrity and good adhesion with various thermoplastic and thermosetting matrices for chopped yarn production.

The adhesion between matrix and fiber can be further improved using blocked isocyanate technology. Special polyurethane dispersions can be produced with blocking groups in the polymer backbone or additives such as Trixene® Aqua BI 201 can be added to the regular size formulation.

Soft-touch Coatings

Soft grades such as Witcobond® 374-13 can be incorporated into coating formulations that modify the haptics (perceptions of tactile stiffness) of normally hard surfaces. Such coatings, eg. automotive interiors and electronic components and provides enhanced aesthetics.

Coating of Hard Surfaces

Alternatively, hard products such as Witcobond® 781 and Witcobond® 457-66 can be used in durable, chemically resistant 1K and 2K systems applied to hard surfaces such as wood, metals, glass, plastic, concrete, and masonry.

Textile Processing

Water-based polyurethane dispersions such as Witcobond ® 363-02 and Witcobond® 737 are widely used in textile processing. Typical applications include fully waterproof and weatherproof coatings, back coats, lamination adhesives, pigment binders used in textile

printing, and garments with imperceptible surfaces on threads and fibers.

Other functional textile use include protective coatings on belts, ropes, braids, optical fibers, and filament yarns.

Urethane coatings require abrasion, chemical, and UV resistance, for which Lanxess can offer a range of solutions. Lanxess has a dedicated polyurethane dispersion laboratory in Latina, Italy that can meet market needs in a variety of coatings and adhesive applications.

The experienced technical team is capable of analytical studies, formulation development,

and synthesis of new products with a high degree of technical differentiation.

With its Witcobond® product line, Lanxess supports users in a wide variety of applications including fiberglass sizing, plastic, glass, and metal surfaces, coatings, and textile finishing.

Increasing demand for VOC (volatile organic compounds) free and low carbon footprint materials, and increasing regulatory pressure on restricted chemicals, Lanxess’s applied research on water-based technologies has made it possible to offer greener technologies and chemistry to Witcobond® users.

Ece Okçu

C.A.S.E. PU Sales Responsible

Kimsel

Formulators of water-based coating systems can choose from a wide variety of Witcobond® polyurethane dispersions. Lanxess offers anionic, nonionic, and cationic grades as well as ester and ether types.

It is possible to offer variations in final coating properties such as hardness, flexibility, toughness, and chemical resistance with Witcobond® products.

Formulators of water-based coating systems can choose from a wide variety of Witcobond® polyurethane dispersions. Lanxess offers anionic, nonionic, and cationic grades as well as ester and ether types.

It is possible to offer variations in final coating properties such as hardness, flexibility, toughness, and chemical resistance with Witcobond® products.

Urethane coatings require abrasion, chemical, and UV resistance, for which Lanxess can offer a range of solutions. Lanxess has a dedicated polyurethane dispersion laboratory in Latina, Italy that can meet market needs in a variety of coatings and adhesive applications.

The experienced technical team is capable of analytical studies, formulation development,

and synthesis of new products with a high degree of technical differentiation.

With its Witcobond® product line, Lanxess supports users in a wide variety of applications including fiberglass sizing, plastic, glass, and metal surfaces, coatings, and textile finishing.

Increasing demand for VOC (volatile organic compounds) free and low carbon footprint materials, and increasing regulatory pressure on restricted chemicals, Lanxess’s applied research on water-based technologies has made it possible to offer greener technologies and chemistry to Witcobond® users.

Urethane coatings require abrasion, chemical, and UV resistance, for which Lanxess can offer a range of solutions. Lanxess has a dedicated polyurethane dispersion laboratory in Latina, Italy that can meet market needs in a variety of coatings and adhesive applications.

The experienced technical team is capable of analytical studies, formulation development,

and synthesis of new products with a high degree of technical differentiation.

With its Witcobond® product line, Lanxess supports users in a wide variety of applications including fiberglass sizing, plastic, glass, and metal surfaces, coatings, and textile finishing.

Increasing demand for VOC (volatile organic compounds) free and low carbon footprint materials, and increasing regulatory pressure on restricted chemicals, Lanxess’s applied research on water-based technologies has made it possible to offer greener technologies and chemistry to Witcobond® users.