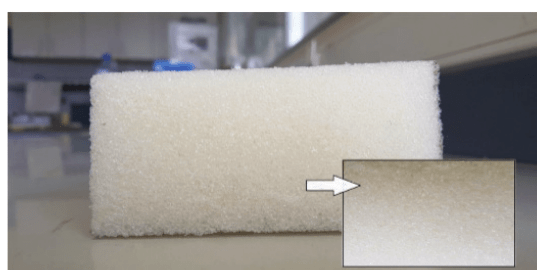

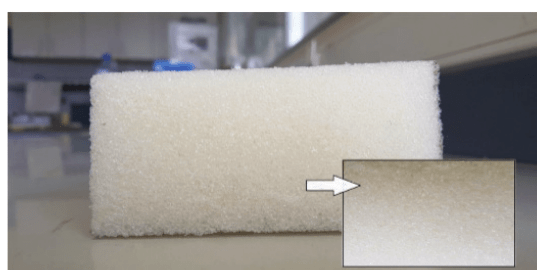

Picture 1. Open-cell foam/ Closed-cell foam

Rigid polyurethane foams has a wide range of applications, which mainly used for cold room doors and panels, building facade insulations, pipe insulations, blinds, tank-silo insulations, packaging foams, refrigerators, roof insulations, tent and greenhouse insulation, decoration products, rock wool adhesives. Flokser Chemical, which has been providing solutions for rigid, flexible and footwear systems in the polyurethane industry since 2006, continues to invest in research and development studies every year at its R&D Center, and makes a difference in its activity fields by providing quality, high production capacity and innovative approach. While the necessity of flame-retardant products is increasing in the spray polyurethane industry, PIR systems cannot be used. The reason is that the spray machines used in the industry can operate with a ratio of 1:1 polyol and isocyanate by volume. However, PIR systems must have a high amount of isocyanate. Flokser Chemical has met the need for flame retardancy in the insulation industry by developing a spray product that can work without losing PIR feature even in 1:1 ratio machines with Creapol RS 3320-36 product.

Picture 2. Burning behavior of PIR systems

Picture 3. Cell structure of low denstiy spray polyurethane system

In Turkey, B2 and B3 class polyurethane foams, which can easily catch fire, are used more than fire-resistant B1 class products in exterior insulation. However, in the construction industry, B1 insulating material requirement is increasing day by day and it becomes a legal obligation for exterior facades have to be made of flame retardant materials in high buildings and the least hardly flammable materials for the other buildings within the scope of “Regulation about fire protection of buildings”. Creapol RC 3430-36 polyol formulation which developed for PIR continuous systems in Flokser Chemical R&D Center is used in the production of metal faced sandwich panels in continuous line panel systems. Creapol RC 3430-36 has B s2 d0 flammability class according to the TS EN 13501-1 standard test results; also, B s1 d0 can be achieved with special applications on the panel. These results for flame retardancy, physical and mechanical properties meet the requirements of the industry.