Introduction

In recent years constantly quest for competitiveness and costs savings, composite materials come up as a suitable alternative to traditional materials like metals or ceramics by bring together lightness and high mechanical performance. Their application areas extend from marine and aeronautic to automotive and sports&leisure equipment’s, but the primary limitation of a steel-to composite changeover appears to be high operation and material costs of composites.

Over the last few years many efforts have been dedicated to make them more competitive although further efforts are required to overcome this problem. Composite materials are mostly getting under thermal curing.

This means that reaction takes place either at elevated temperature, including high energy consumption, or at ambient temperature and thus a very slow process. [1]. The demand for mass production of the sectors using composite materials have been paved the way for the development of new hardening mechanisms.

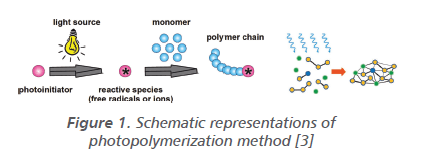

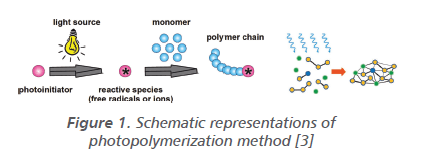

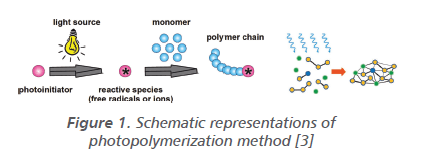

Photopolymerization is an efficient, economic and environment-friendly technique for fast generation of solid crosslinked polymer networks from liquid resin systems. Photopolymerization formulations comprise usually of multifunctional monomers and oligomers, with small quantity of photo initiator that classified by the reactive species and polymerization mechanism. UV light exposure either produces free radicals, that start polymerization of monomers like unsaturated polyesters or acrylates, or cations, that further polymerization of multifunctional vinyl ethers or epoxides [2].

- Advantages of light curing compared to thermal curing;

• Reactions that take hours at ambient temperature

can be carried out in minutes via photopolymerization,

• Low energy consumption due to no heating required,

• Low cost equipment usage and low thermal stresses.

Due to photopolymerization is a reliable and less dangerous method, it is preferred for many applications. When compared with thermal curing, photopolymerization has many advantages, so it is widely used for curing of relatively thin polymeric films in applications such as inks, adhesives, paints and fast drying varnishes as well as in the manufacturing optical disks, microcircuits and printing plates. Another field of application are denture prosthesis and rapid prototyping by way of stereolithography [2].

Figure 2. Industrial scale UV curing machine [4]

The use of light to manufacture composites parts is an interesting and new technology that has gained popularity in recent years. The major limitation to use of light to produce composites is that the beams of light need to pass through the material to create reactive species. The presence of the fibers as reinforcing component may also get worse the transmission of light.

UV curing is a good technology when it comes to thin films or coatings, but it needs adjustments towards to the curing of thick materials. Some studies successfully report the production of glass-fibers reinforced unsaturated polyester, vinyl ester or acrylate composites using UV curing [1,5,6] however, fiber reinforced epoxy composites produced via photopolymerization is very limited.

Photopolymerization of Epoxy Resins

Epoxy resins are high performance thermoset based polymeric materials used in many fields of industry. These resins’ value was more than US$7.5 billion in 2015 and are mostly formulated in two parts with anhydrides or amines as hardener. These formulations are known to require long curing times at ambient temperature or short curing times with additional heating [7]. One of the most commonly used epoxy compound is diglycidylether bisphenol-A (DGEBA) [8].

Figure 3. Chemical representation of DGEBA based epoxy resin

Photopolymerization can be used to activate epoxy curing as an interesting alternative to thermal curing. To carry out photopolymerization of epoxy resin, the use of cationic photo initiators (e.g. diary iodonium, triaryl sulfonium salts) that are called photo acid generators (PAGs) is required [9].

Figure 4. Chemical structures of the most commonly

used photo initiators of cationic polymerization. Typical

R groups include H, CH3, CH3O, Cl and NO2 [10].

These photo initiators cleavage when exposed by UV light and form strong Bronsted acids (HX). The strong acids are able to start cationic ring-opening polymerization of an epoxy resin [11]. At the end of the reaction, the polymeric structure is crosslinked and cured (Figure 5).

X is the counter anion and is generally SbF6-, PF6-,

BF4-.

Nevertheless, the photopolymerization of epoxy resin is limited to thin film (100-200 μm) applications due to a low penetration depth of UV-light. Moreover, the existence of fillers or fibers in the epoxy matrix could block the light penetration to deeper layers [11]. For these reasons, the curing of epoxy only via photopolymerization mechanism is not a sufficient method for thick and reinforced parts.

In recent years the radical induced cationic frontal polymerization (RICFP) was used as an energy efficient process to cure DGEBA in thick applications [9,11]. This method is ideal to overcome typical troubles during application like, limited layer thickness, high energy required thermal curing and insufficient pot life [8].

Radical Induced Cationic Frontal Polymerization (RICFP)

The decomposition of the photo initiator can be stimulated either by light or else by a redox reaction with proper radicals, leading to the radical induced cationic polymerization (RICP) process. Some basic research articles have been published on this subject [12,13,14]. The reactive radicals are formed by the thermal cleavage of conventional radical thermal initiators (RTIs) such as azobis (isobutyronitrile) (AIBN), dibenzoyl peroxide (BPO), or C-C labile compounds like benzo pinacol (TPED, see also Fig. 7). The drawback of this technique is that the entire formulation needs to be heated for curing [9].

To overcome this problem, an alternative curing method called frontal polymerization (FP) can be used. FP is a reaction that after a suitable exciter, a local reaction occurs and it will initiate further reaction in its adjacent zones and therefore FP is assumed that a moving reaction. The progress of this reaction is generally thanks to the thermal decomposition of proper initiators. The required heat for the reaction is provided from exothermic heat of the polymerization [9]. It was researched in detail by Pojman et al. [15,16].

Radical induced cationic frontal polymerization (RICFP) that is the recommended mechanism combines the radical induced cationic polymerization (RICP) and frontal polymerization (FP) [17]. The RICFP process enables the DGEBA-based epoxy resin to cure through the thickness in the presence of a thermal initiator and a cationic photo initiator. This process can be applied in aliphatic and cycloaliphatic epoxy resins.

The formation of the curing catalyst from the cationic photo initiators is achieved by irradiation with UV light to initiate the polymerization. The radical thermal initiator is triggered by the polymerization heat. The formed radicals decompose the cationic initiator in regions which cannot be reached by UV light [18]. This cycle proceeds as a chain reaction and curing is carried out through the thickness of the part.

Figure 6. Schematic representation of the RICFP

process

Figure 7. Representation of the activation of the

thermal/radical initiator (TPED) followed by the

operating mechanism with diary iodonium salt [11]

RIFCP method does not adversely affect the thermomechanical and electrical properties of the cured resin and has many advantages;

• Fast curing,

• Long pot life of formulation,

• Energy efficient,

• Easy to find and common components,

• Low cost chemicals,

• Works excellent even with low reactive epoxy resins

like DGEBA,

• Polymerization can be initiated with UV light or local

application of heat,

• Applicable to complex shaped parts.

Applications of RICFP method;

• Repairing applications,

• Automotive&aeronautic parts,

• Joint bolts,

• Production of composite materials on epoxy base.

In this system the curing process of epoxy resin can occur even in the presence of inorganic fillers or fiber reinforcements as long as the reaction temperature is maintained.

Use of RICFP Method in Composites

In literature, there is a few studies on the production of epoxy-based fiber reinforced composites via RICFP process. In a pioneer work by Sangermano et al. [11] the UV induced polymerization of an epoxy-glass fibers composite was reported first time. The epoxy formulation included a diaryliodonium hexafluoro antimonate salt, as photo initiator, and benzo pinacol as thermal initiator. Glass fiber reinforced composites consisting 2-layer unidirectional glass-fiber fabric were prepared by hand layup technique and cured via the RICFP method in only 1 minute. The properties of the UV cured composite were compared with the composite that thermally cured with amine hardener and had same fiber content. The test results of the composites characterized by tensile testing and dynamic mechanical analysis (DMA) are shown in Table 1.

Table 1. Properties of glass fiber reinforced epoxy composites [11]

The crosslinked composite get by RICFP showed a little bit better properties by comparison with the thermally cured composite. Thanks to this method, it has been shown that glass fiber reinforced epoxy composites can be produced at high speed at room temperature while maintaining thermo-mechanical properties [11].

In another study by Sangermano et al., the RICFP method was applied for carbon fiber reinforced composites and results confirming the previous study [19].

Conclusion

RICFP is a promising method for energy efficient and fast curing of epoxies for many applications including the production of composite materials. It lies upon do more researches to push the limits of this technique and develop new methods for the manufacturing of light cured composites.

References

[1] P. Carion, A. Ibrahim, X. Allonas, C. Croutxé-Barghorn, ve G. L’Hostis, “Frontal free-radical photopolymerization of thick samples:

Applications to LED-induced fiber-reinforced polymers”, Journal of Polymer Science Part A: Polymer Chemistry, c. 57, sy 8, ss. 898-906, Nis. 2019.

[2] Y. Yagci, S. Jockusch, ve N. J. Turro, “Photoinitiated Polymerization: Advances, Challenges, and Opportunities”, Macromolecules, c. 43, sy 15, ss. 6245-6260, Ağu. 2010.

[3] A. Endruweit, M. S. Johnson, ve A. C. Long, “Curing of composite components by ultraviolet radiation: A review”, Polymer Composites, c. 27, sy 2, ss. 119-128, Nis. 2006.

[4] Dymax. “Achieve Fast, Reliable Cures With UV Curing Conveyor Systems”. Erişim: 27 Ekim 2019. https://dymax.com/light-curingequipment/ conveyor-systems/

[5] X. Zhang, Y. Duan, X. Zhao, ve D. Li, “UV stepwise cured fabrication of glass fiber/acrylate composites: Effects of exposure dose

on curing uniformity and interlaminar shear strength”, Journal of Composite Materials, c. 50, sy 10, ss. 1395-1401, May. 2016.

[6] B. Hasiaoui vd., “Free radical photopolymerization process for fiber-reinforced polymer: Effect on the mechanical properties”, Polymers for Advanced Technologies, c. 30, sy 4, ss. 902-909, Nis. 2019.

[7] P. Knaack, N. Klikovits, A. D. Tran, D. Bomze, ve R. Liska, “Radical induced cationic frontal polymerization in thin layers”, Journal of Polymer Science Part A: Polymer Chemistry, c. 57, sy 11, ss. 1155- 1159, Haz. 2019.

[8] M. Birkner, A. Seifert, ve S. Spange, “Radical induced cationic frontal twin polymerization of Si-spiro compound in combination with bisphenol-A-diglycidylether”, Polymer, c. 160, ss. 19-23, Oca. 2019.

[9] D. Bomze, P. Knaack, T. Koch, H. Jin, ve R. Liska, “Radical induced cationic frontal polymerization as a versatile tool for epoxy curing and composite production”, Journal of Polymer Science Part A: Polymer Chemistry, c. 54, sy 23, ss. 3751-3759, Ara. 2016.

[10] T. Vidil, F. Tournilhac, S. Musso, A. Robisson, ve L. Leibler, “Control of reactions and network structures of epoxy thermosets”, Progress in Polymer Science, c. 62, ss. 126-179, Kas. 2016.

[11] M. Sangermano, A. D’Anna, C. Marro, N. Klikovits, ve R. Liska, “UV-activated frontal polymerization of glass fibre reinforced epoxy composites”, Composites Part B: Engineering, c. 143, ss. 168-171, Haz. 2018.

[12] Y. Yagci ve I. Reetz, “Externally stimulated initiator systems for cationic polymerization”, Progress in Polymer Science, c. 23, sy 8, ss. 1485-1538, Ara. 1998.

[13] J. V. Crivello ve S. Liu, “Free Radical Induced Acceleration of Cationic Photopolymerization”, Chemistry of Materials, c. 10, sy 11, ss. 3724-3731, Kas. 1998.

[14] S. K. Rajaraman, W. A. Mowers, ve J. V. Crivello, “Interaction of epoxy and vinyl ethers during photoinitiated cationic polymerization”, Journal of Polymer Science Part A: Polymer Chemistry, c. 37, sy

21, ss. 4007-4018, Kas. 1999.

[15] J. A. Pojman, W. Elcan, A. M. Khan, ve L. Mathias, “Binary frontal polymerization: A new method to produce simultaneous interpenetrating polymer networks (SINs)”, Journal of Polymer Science Part A: Polymer Chemistry, c. 35, sy 2, ss. 227-230, Oca. 1997.

[16] S. Scognamillo, C. Bounds, S. Thakuri, A. Mariani, Q. Wu, ve J. A. Pojman, “Frontal cationic curing of epoxy resins in the presence of defoaming or expanding compounds”, Journal of Applied Polymer Science, c. 131, sy 11, s. n/a-n/a, Haz. 2014.

[17] N. Klikovits, R. Liska, A. D’Anna, ve M. Sangermano, “Successful UV-Induced RICFP of Epoxy-Composites”, Macromolecular Chemistry and Physics, c. 218, sy 18, s. 1700313, Eyl. 2017.

[18] D. Bomze, P. Knaack, ve R. Liska, “Successful radical induced cationic frontal polymerization of epoxy-based monomers by C–C labile compounds”, Polymer Chemistry, c. 6, sy 47, ss. 8161-8167, 2015.

[19] M. Sangermano, I. Antonazzo, L. Sisca, ve M. Carello, “Photoinduced cationic frontal polymerization of epoxy–carbon fibre composites”, Polymer International, c. 68, sy 10, ss. 1662-1665, Eki. 2019.

The crosslinked composite get by RICFP showed a little bit better properties by comparison with the thermally cured composite. Thanks to this method, it has been shown that glass fiber reinforced epoxy composites can be produced at high speed at room temperature while maintaining thermo-mechanical properties [11].

In another study by Sangermano et al., the RICFP method was applied for carbon fiber reinforced composites and results confirming the previous study [19].

The crosslinked composite get by RICFP showed a little bit better properties by comparison with the thermally cured composite. Thanks to this method, it has been shown that glass fiber reinforced epoxy composites can be produced at high speed at room temperature while maintaining thermo-mechanical properties [11].

In another study by Sangermano et al., the RICFP method was applied for carbon fiber reinforced composites and results confirming the previous study [19].