Feldspar is an aluminum silicate group mineral consisting of sodium, potassium, calcium and rarely barium, cesium and isomorphic composition of these minerals (Heyes et al., 2013; Zhang et al., 2018). It is one of the most abundant minerals in the world and constitutes approximately 60% of the earth’s crust (Vidyadhar et al., 2002). According to the report of United States Geological Survey, Turkey ranks first in the world with 7.500 million tons of feldspar production in 2019.

Feldspar minerals are named according to their K, Na and Ca ratios. Na-feldspars are known as albite (NaAlSi3), K-feldspars orthoclase/microcline and Ca-feldspars as anorthite (Kangal et al., 2017). Due to their alkali and alumina content, they have an important place in various industrial applications. Alkali feldspars (potassium feldspars) are widely used in the paint, glass and ceramic industry industries.

The Fe2O3 content of potassium and sodium feldspars used in the glass industry must be less than 0.2% and 0.3%, respectively, because of the the quality standarts. On the other hand, it is expected that the amount of Fe2O3 contained in potassium feldspars in the ceramic industry will be less than 0.5%.

Feldspar is mostly found in pegmatic and feldspathic sand deposits together with silica group minerals such as mica, quartz and spodumen. Flotation is one of the most preferred methods for the separation of silicate group minerals found with feldspars using fatty acids flotation (Xu et al., 2017).

Feldspar minerals have a negative surface charge at many pH values. Isoelectric point is observed approximately pH 1.5. The reason for this situation Si-O and Al-O bonds in the crystal structure are broken during grinding. When ions such as Na +, K + and Ca + on the surface dissolve into the solution, the surface becomes negatively charged (Fuerstenau and Raghavan 1977; Gülgönül et al., 2007).

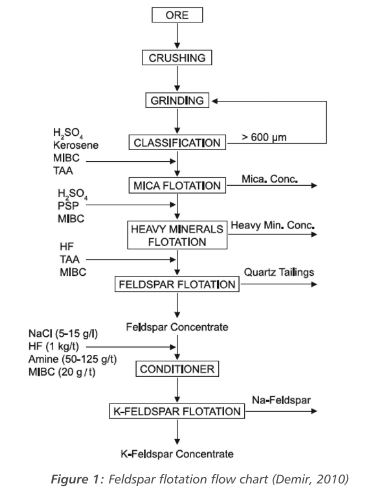

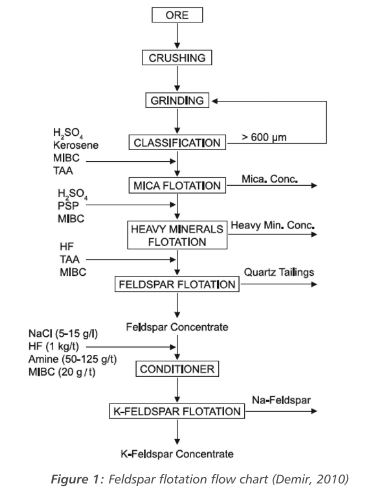

For the separation of feldspar minerals from gangue minerals, beneficiation methods based on magnetic sensitivity and specific gravity differences, and flotation and leaching techniques, a chemical method that benefit from the physico-chemical properties of minerals are used. High impurity feldspar can be obtained by combining one or more of these methods together. Stepwise flotation method is accepted and widely applied to separate the feldspar with its silicate group from minerals and metal oxides. Before the flotation process, the slime size material is removed and the negative effects caused by iron and clay minerals of this size group are prevented. Figure 1 shows the classical flotation flow chart using feldspar flotation.

The slime sized material (≤ 38 µm) is separated before feldspar flotation which contain significant amount of feldspar as well as iron and clay minerals it contains. Therefore, in order to prevent this loss, different flotation techniques for the beneficiation of fine minerals are successfully carried out with laboratory scale (Karagüzel 2010). But, industrial application in Turkey are not yet widely available.

The slime sized material (≤ 38 µm) is separated before feldspar flotation which contain significant amount of feldspar as well as iron and clay minerals it contains. Therefore, in order to prevent this loss, different flotation techniques for the beneficiation of fine minerals are successfully carried out with laboratory scale (Karagüzel 2010). But, industrial application in Turkey are not yet widely available.

Referanslar/ References • Demir, C. (2010). Selective Separation of Na- And K-Feldspar from Weathered Granites by Flotation in HF Medium. Ceramics-Silikaty, 54(1), 60-64.

• Fuerstenau, D.V., Raghavan, S., 1977. Proc. XII International Mineral Processing Congress. Nacional Publicacoes e publicidade S/C Ltda. 2, 3–8 Septemper, pp. 368–415. Sao Paula—Brazil.

• Gülgönül, I., Karagüzel, C., & Çelik, M. S., (2008). Surface vs. bulk analyses of various feldspars and their significance to flotation. International journal of mineral processing, 86(1-4), 68-74.

• Heyes, G. W., Allan, G. C., Bruckard, W. J., & Sparrow, G. J., (2012). Review of flotation of feldspar. Mineral Processing and Extractive Metallurgy, 121(2), 72-78.

• Kangal, M. O., Bulut, G., Yeşilyurt, Z., Güven, O., & Burat, F., (2017). An alternative source for ceramics and glass raw materials: Augen-Gneiss. Minerals, 7(5), 70.

• Karagüzel, C. (2010). Selective separation of fine albite from feldspathic slime containing colored minerals (Fe-Min) by batch scale dissolved air flotation (DAF). Minerals Engineering, 23(1), 17-24.

• Vidyadhar, A., Rao, K. H., & Forssberg, K. S. E., (2002). Separation of feldspar from quartz: Mechanism of mixed cationic/anionic collector adsorption on minerals and flotation selectivity. Mining, Metallurgy & Exploration, 19(3), 128-136.

• Xu, L., Tian, J., Wu, H., Deng, W., Yang, Y., Sun, W., & Hu, Y., (2017). New insights into the oleate flotation response of feldspar particles of different sizes: anisotropic adsorption model. Journal of colloid and interface science, 505, 500-508.

• Zhang, Y., Hu, Y., Sun, N., Liu, R., Wang, Z., Wang, L., & Sun, W., (2018). Systematic review of feldspar beneficiation and its comprehensive application. Minerals Engineering, 128, 141-15

[caption id="attachment_126410" align="alignnone" width="184"]

Araştırma Görevlisi

Berivan Tunçİstanbul Teknik Üniversitesi

Maden Fakültesi

Cevher Hazırlama Mühendisliği Bölümü[/caption]

[caption id="attachment_126411" align="alignnone" width="177"]

Prof. Dr. Gülay Bulut

Prof. Dr. Gülay Bulutİstanbul Teknik Üniversitesi

Maden Fakültesi

Cevher Hazırlama Mühendisliği Bölümü[/caption]

Feldspar minerals are named according to their K, Na and Ca ratios. Na-feldspars are known as albite (NaAlSi3), K-feldspars orthoclase/microcline and Ca-feldspars as anorthite (Kangal et al., 2017). Due to their alkali and alumina content, they have an important place in various industrial applications. Alkali feldspars (potassium feldspars) are widely used in the paint, glass and ceramic industry industries.

Feldspar minerals are named according to their K, Na and Ca ratios. Na-feldspars are known as albite (NaAlSi3), K-feldspars orthoclase/microcline and Ca-feldspars as anorthite (Kangal et al., 2017). Due to their alkali and alumina content, they have an important place in various industrial applications. Alkali feldspars (potassium feldspars) are widely used in the paint, glass and ceramic industry industries.

The slime sized material (≤ 38 µm) is separated before feldspar flotation which contain significant amount of feldspar as well as iron and clay minerals it contains. Therefore, in order to prevent this loss, different flotation techniques for the beneficiation of fine minerals are successfully carried out with laboratory scale (Karagüzel 2010). But, industrial application in Turkey are not yet widely available.

The slime sized material (≤ 38 µm) is separated before feldspar flotation which contain significant amount of feldspar as well as iron and clay minerals it contains. Therefore, in order to prevent this loss, different flotation techniques for the beneficiation of fine minerals are successfully carried out with laboratory scale (Karagüzel 2010). But, industrial application in Turkey are not yet widely available.

The slime sized material (≤ 38 µm) is separated before feldspar flotation which contain significant amount of feldspar as well as iron and clay minerals it contains. Therefore, in order to prevent this loss, different flotation techniques for the beneficiation of fine minerals are successfully carried out with laboratory scale (Karagüzel 2010). But, industrial application in Turkey are not yet widely available.

The slime sized material (≤ 38 µm) is separated before feldspar flotation which contain significant amount of feldspar as well as iron and clay minerals it contains. Therefore, in order to prevent this loss, different flotation techniques for the beneficiation of fine minerals are successfully carried out with laboratory scale (Karagüzel 2010). But, industrial application in Turkey are not yet widely available.

Araştırma Görevlisi

Araştırma Görevlisi Prof. Dr. Gülay Bulut

Prof. Dr. Gülay Bulut