Engineers are being trained by 3M and Ansys to improve adhesive joint design and drive sustainability.

Ansys Learning Hub courses taught by 3M research scientists help engineers develop innovative designs using tapes and adhesives while eliminating material waste.

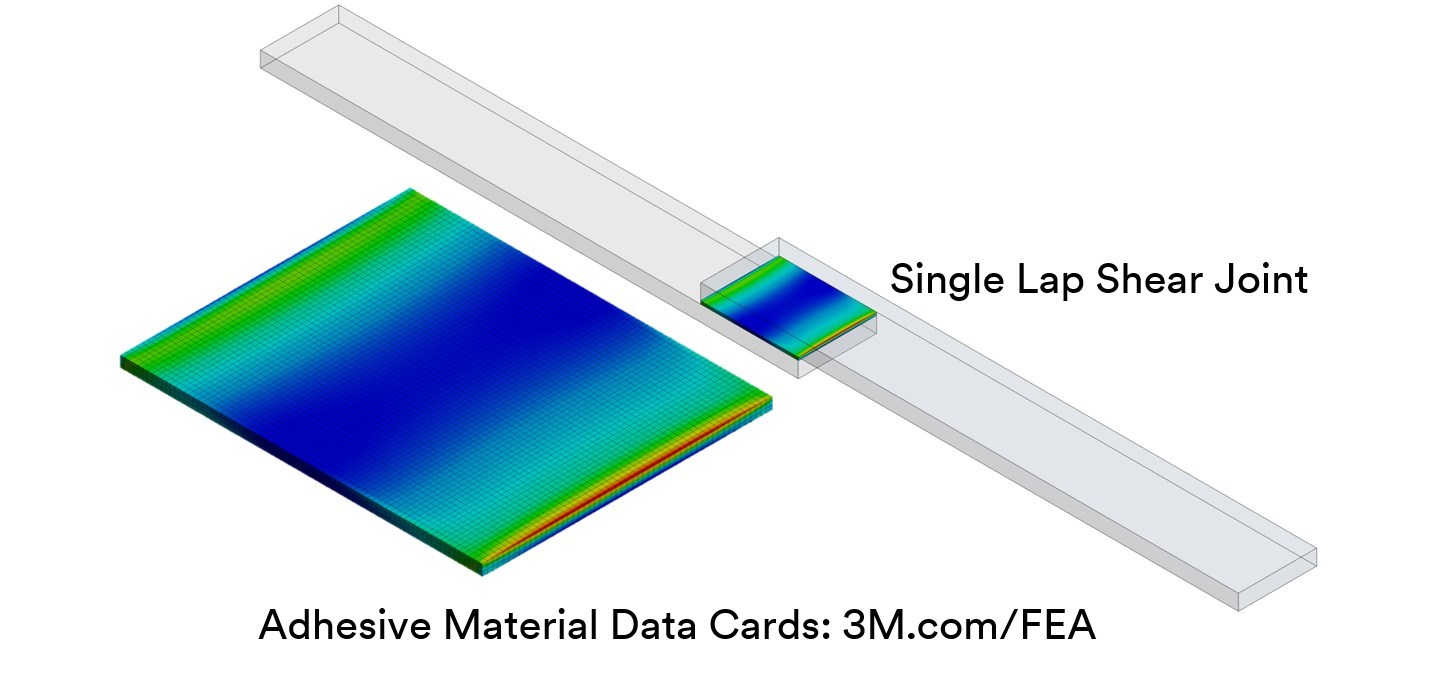

[caption id="attachment_133326" align="aligncenter" width="1436"]

Ansys Learning Hub courses taught by 3M research scientists help engineers develop innovative designs using tapes and adhesives while eliminating material waste.[/caption]

3M (NYSE: MMM) and Ansys (NYSE: ANSS) have launched a material modeling training program to aid engineers in refining product development processes, speeding up the design stage, and reducing material waste. Engineers are utilizing the program to better develop and analyze simulations, improve designs, and speed up the time to market for next-generation products that include tape and adhesive.

3M is the industry leader in the development and distribution of adhesives used in a variety of industries, including industrial equipment, health care, worker safety, and consumer goods. 3M scientists and engineers employ Ansys technologies throughout the adhesive development cycle to ensure that adhesives preserve structural integrity.

When examining modern polymeric materials, simulation allows engineers to significantly increase sustainability and confirm engineering decisions. Engineers frequently struggle to gather precise engineering data on tapes and adhesives in order to run simulations effectively, resulting in waste and additional prototype cycles, which impedes sustainability efforts.

To address this issue, 3M and Ansys teamed up to develop a material modeling training program for engineers that teaches them how to model with tape and structural adhesives, optimize adhesive and joint design, reduce waste, and increase production efficiency. 3M also provides Ansys users with certified FE material models for their tape and adhesive products.

"Together with Ansys, 3M is creating a leading-edge learning environment that will educate current and future engineering workforces on how to harness powerful material science and digital engineering solutions to increase productivity, win the race to market and substantially improve environmental sustainability," said Rebecca Miller, Vice President, Structural Adhesives at 3M Industrial Adhesives and Tapes Division. "Through this program, engineers will learn core principles and processes to overcome highly complex engineering challenges."

Three industry-level learning modules for adhesive modeling and simulation are now accessible in the Ansys Learning Hub as part of the first phase of this program (ALH). ALH is a learning and development program powered by Ansys that houses digital engineering solution training and adoption materials for a variety of verticals.

These courses mix on-demand and instructor-led instruction from 3M researchers and engineers. All ALH clients will be able to participate in the campaign. The series will grow over time to become a guided learning program that covers several important material modeling engineer competencies and will be accredited and integrated into the material industry's qualification process.

Ansys Learning Hub is an on-demand portal that offers Ansys customers a continuous learning curriculum that includes 450 Ansys training courses, over 1,200 self-paced workshops for hands-on practice, 400 hours of topical lecture videos, and over 200 virtual and live training events led by Ansys experts each year. There are additional tools for managing educational goals and instructor-moderated breakout rooms included in the program.

"Engineers can significantly reduce costly material waste and help power team-wide environmental sustainability by mastering a rapid and robust solution that helps determine the optimum adhesive and joint design for bonding applications," said Shane Emswiler, senior vice president at Ansys. "Through this training program with 3M, we are empowering engineers to enhance their skill set, increase production efficiency, slash material waste and speed products to market."

Kaynak

Ansys Learning Hub courses taught by 3M research scientists help engineers develop innovative designs using tapes and adhesives while eliminating material waste.[/caption]

3M (NYSE: MMM) and Ansys (NYSE: ANSS) have launched a material modeling training program to aid engineers in refining product development processes, speeding up the design stage, and reducing material waste. Engineers are utilizing the program to better develop and analyze simulations, improve designs, and speed up the time to market for next-generation products that include tape and adhesive.

3M is the industry leader in the development and distribution of adhesives used in a variety of industries, including industrial equipment, health care, worker safety, and consumer goods. 3M scientists and engineers employ Ansys technologies throughout the adhesive development cycle to ensure that adhesives preserve structural integrity.

When examining modern polymeric materials, simulation allows engineers to significantly increase sustainability and confirm engineering decisions. Engineers frequently struggle to gather precise engineering data on tapes and adhesives in order to run simulations effectively, resulting in waste and additional prototype cycles, which impedes sustainability efforts.

To address this issue, 3M and Ansys teamed up to develop a material modeling training program for engineers that teaches them how to model with tape and structural adhesives, optimize adhesive and joint design, reduce waste, and increase production efficiency. 3M also provides Ansys users with certified FE material models for their tape and adhesive products.

"Together with Ansys, 3M is creating a leading-edge learning environment that will educate current and future engineering workforces on how to harness powerful material science and digital engineering solutions to increase productivity, win the race to market and substantially improve environmental sustainability," said Rebecca Miller, Vice President, Structural Adhesives at 3M Industrial Adhesives and Tapes Division. "Through this program, engineers will learn core principles and processes to overcome highly complex engineering challenges."

Three industry-level learning modules for adhesive modeling and simulation are now accessible in the Ansys Learning Hub as part of the first phase of this program (ALH). ALH is a learning and development program powered by Ansys that houses digital engineering solution training and adoption materials for a variety of verticals.

These courses mix on-demand and instructor-led instruction from 3M researchers and engineers. All ALH clients will be able to participate in the campaign. The series will grow over time to become a guided learning program that covers several important material modeling engineer competencies and will be accredited and integrated into the material industry's qualification process.

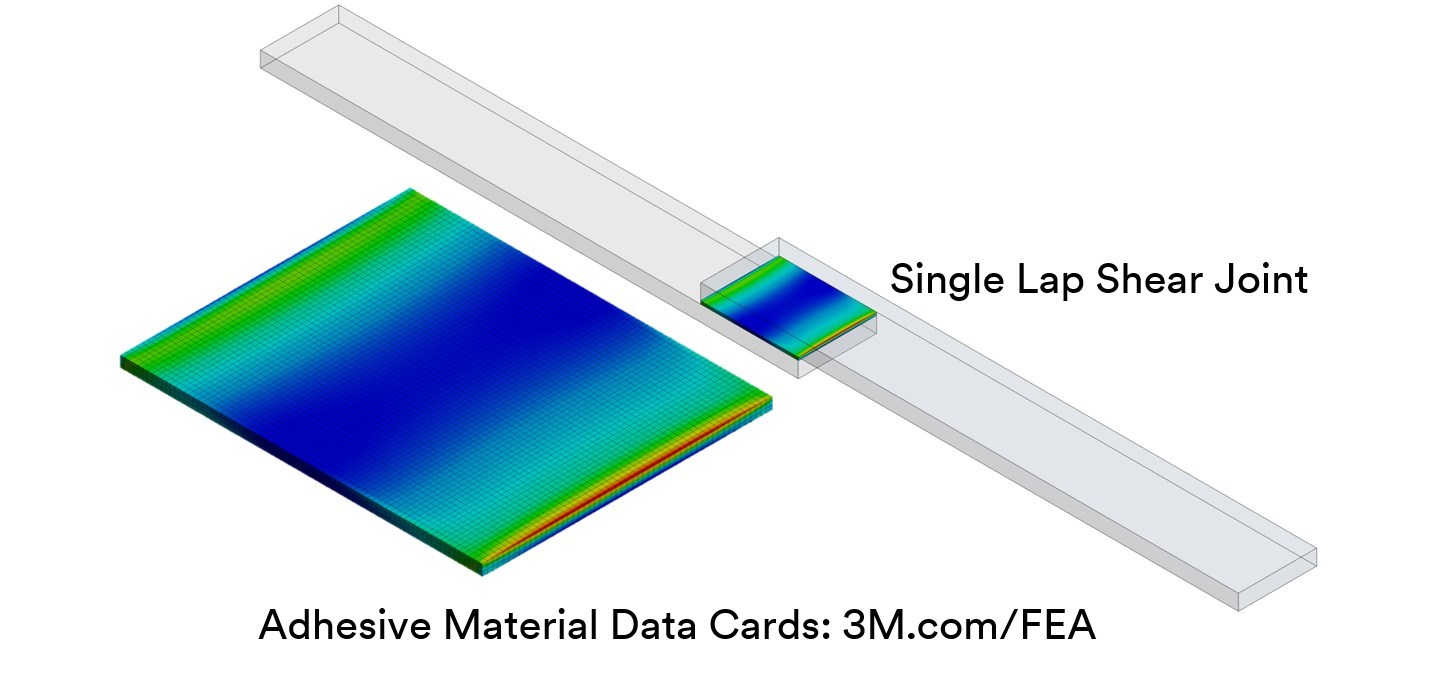

Ansys Learning Hub courses taught by 3M research scientists help engineers develop innovative designs using tapes and adhesives while eliminating material waste.[/caption]

3M (NYSE: MMM) and Ansys (NYSE: ANSS) have launched a material modeling training program to aid engineers in refining product development processes, speeding up the design stage, and reducing material waste. Engineers are utilizing the program to better develop and analyze simulations, improve designs, and speed up the time to market for next-generation products that include tape and adhesive.

3M is the industry leader in the development and distribution of adhesives used in a variety of industries, including industrial equipment, health care, worker safety, and consumer goods. 3M scientists and engineers employ Ansys technologies throughout the adhesive development cycle to ensure that adhesives preserve structural integrity.

When examining modern polymeric materials, simulation allows engineers to significantly increase sustainability and confirm engineering decisions. Engineers frequently struggle to gather precise engineering data on tapes and adhesives in order to run simulations effectively, resulting in waste and additional prototype cycles, which impedes sustainability efforts.

To address this issue, 3M and Ansys teamed up to develop a material modeling training program for engineers that teaches them how to model with tape and structural adhesives, optimize adhesive and joint design, reduce waste, and increase production efficiency. 3M also provides Ansys users with certified FE material models for their tape and adhesive products.

"Together with Ansys, 3M is creating a leading-edge learning environment that will educate current and future engineering workforces on how to harness powerful material science and digital engineering solutions to increase productivity, win the race to market and substantially improve environmental sustainability," said Rebecca Miller, Vice President, Structural Adhesives at 3M Industrial Adhesives and Tapes Division. "Through this program, engineers will learn core principles and processes to overcome highly complex engineering challenges."

Three industry-level learning modules for adhesive modeling and simulation are now accessible in the Ansys Learning Hub as part of the first phase of this program (ALH). ALH is a learning and development program powered by Ansys that houses digital engineering solution training and adoption materials for a variety of verticals.

These courses mix on-demand and instructor-led instruction from 3M researchers and engineers. All ALH clients will be able to participate in the campaign. The series will grow over time to become a guided learning program that covers several important material modeling engineer competencies and will be accredited and integrated into the material industry's qualification process.

Ansys Learning Hub is an on-demand portal that offers Ansys customers a continuous learning curriculum that includes 450 Ansys training courses, over 1,200 self-paced workshops for hands-on practice, 400 hours of topical lecture videos, and over 200 virtual and live training events led by Ansys experts each year. There are additional tools for managing educational goals and instructor-moderated breakout rooms included in the program.

"Engineers can significantly reduce costly material waste and help power team-wide environmental sustainability by mastering a rapid and robust solution that helps determine the optimum adhesive and joint design for bonding applications," said Shane Emswiler, senior vice president at Ansys. "Through this training program with 3M, we are empowering engineers to enhance their skill set, increase production efficiency, slash material waste and speed products to market."

Kaynak

Ansys Learning Hub is an on-demand portal that offers Ansys customers a continuous learning curriculum that includes 450 Ansys training courses, over 1,200 self-paced workshops for hands-on practice, 400 hours of topical lecture videos, and over 200 virtual and live training events led by Ansys experts each year. There are additional tools for managing educational goals and instructor-moderated breakout rooms included in the program.

"Engineers can significantly reduce costly material waste and help power team-wide environmental sustainability by mastering a rapid and robust solution that helps determine the optimum adhesive and joint design for bonding applications," said Shane Emswiler, senior vice president at Ansys. "Through this training program with 3M, we are empowering engineers to enhance their skill set, increase production efficiency, slash material waste and speed products to market."

Kaynak