Weighing in Hazardous Areas – Safe – Easy – Flexible The Right Weighing Equipment for Completely Reliable Accurate Results in Hazardous Areas

At METTLER TOLEDO, our goal is to provide robust and safe processes in every area of weighing applications.

While Process Safety affects the most important parameters such as efficiency, quality and productivity, it keeps employees, the most valuable part of a business, safe.

Today, with the developing technology, it has become possible to take more effective and faster safety measures. It is our primary goal to meet safety requirements in every material we develop.

Moreover, we offer solutions to help ensure Process Safety directly. As an example of these solutions, you can keep your business safe at all times with METTLER TOLEDO Hazardous Area Weighing Solutions.

We help to avoid industrial accidents with our industrial weighing solutions that we offer in compliance with hazardous area regulations.

With our comprehensive hazardous area solutions, we enable our customer to select the right equipment for your hazardous area application and work in compliance with regulations.

Security and compliance with standards; this is of great importance when working in harsh, potentially explosive environments. Safe weighing equipment is ideal for weighing in hazardous areas as it keeps the entire system safe regardless of the weighing application.

Safe technologies prevents explosions by ensuring that the energy transferred to a hazardous area is well below the energy to trigger the explosion.

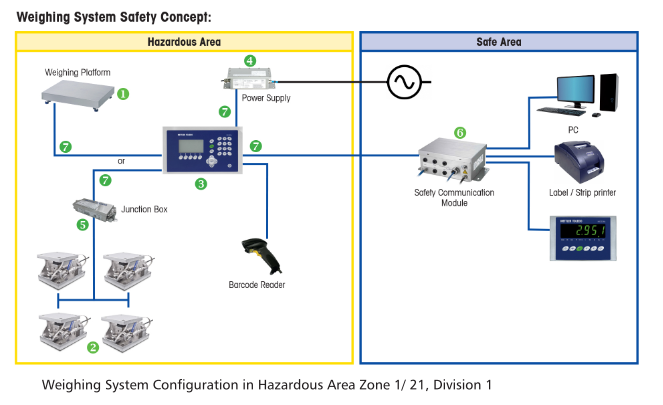

[caption id="attachment_130016" align="aligncenter" width="663"]

Weighing System Configuration in Hazardous Area Zone 1/ 21, Division 1[/caption]

At METTLER TOLEDO, we offer a wide range of compact scales, bench scales, floor scales, load cells, weigh modules and truck scales from which customer can choose the right weighing device.

Our safe weighing terminals provide the functionality they need, from manual basic weighing applications to semi- or fully automated process control, while standard communication interfaces provide unmatched integration with their process environment.

In addition to all these, customer can accelerate their workflows with the flexibility of using mobile batteries.

Consistent dosing, filling and mixing processes are the key to sustainable and high product quality.

When choosing the right weighing equipment to be used in hazardous areas, the appropriate method for the correct classification and protection class should be considered.

Using safe weighing devices keeps your product quality at the highest level by providing accurate and reliable weighing results with the highest levels of protection.

As the METTLER TOLEDO Turkey sales and service team, we would like to state that we are ready when the customer want to exchange information in all processes, from choosing the right equipment to all maintenance operations that must be done throughout its lifecycle.

No matter where in the world user are operating under any regulation, our solutions are designed and tested in accordance with IECEX, ATEX, FM and Local standards or regulations and are approved worldwide for maximum safety of their processes.

Safety from Design to Routine Operation

In hazardous areas, minor errors and malfunctions can have irreparable consequences. To avoid these consequences, standards and regulations cover not only the right equipment design and selection, but also how an equipment will function throughout its lifetime.

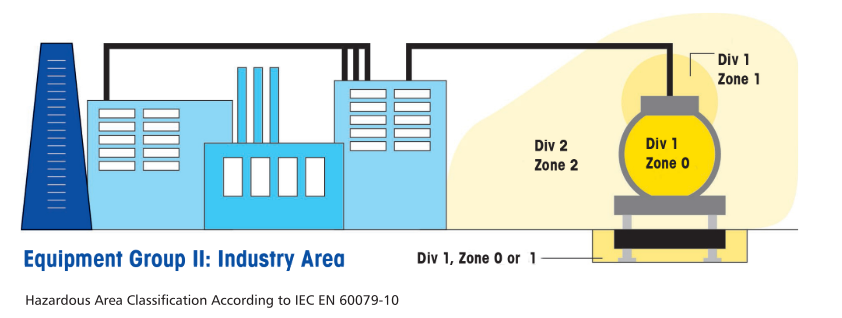

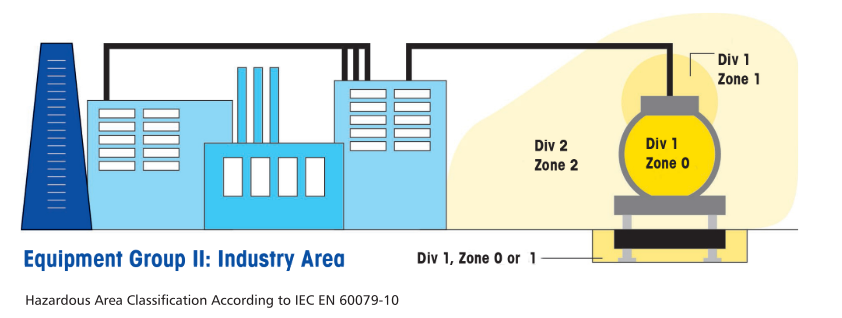

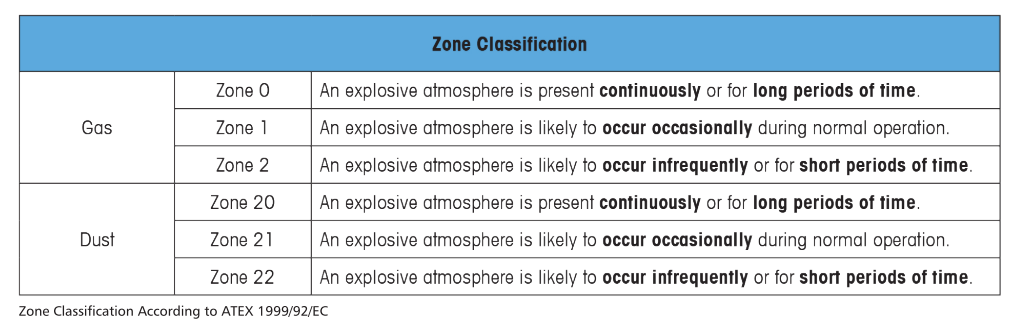

[caption id="attachment_130017" align="aligncenter" width="842"]

Hazardous Area Classification According to IEC EN 60079-10[/caption]

Weighing equipment for hazardous areas is designed for safe use in such environments and it is essential that its function and integrity be maintained through out its lifetime from installation. The IEC 60079 series of standards on the use of electrical equipment in hazardous areas covers two important areas:

• IEC 60079-14: Design, Selection and Installation of Equipment

• IEC 60079-17: Regular Inspection and Maintenance of Equipment

These international standards form the basis for national occupational safety and hazardous area regulations.

As METTLER TOLEDO, we are at the customer side with our expertise in compliance with all requirements of the relevant standards, documentation, correct data storage, data integration, correct use of equipment, and regular inspection and maintenance.

Uğur Tuncer

Business Unit Manager

Industrial Section

METTLER TOLEDO

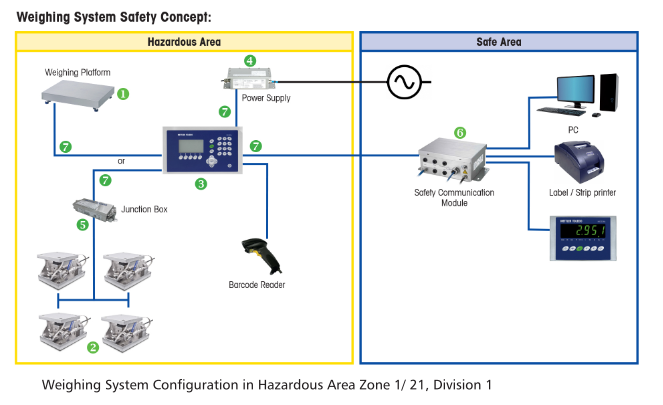

Weighing System Configuration in Hazardous Area Zone 1/ 21, Division 1[/caption]

At METTLER TOLEDO, we offer a wide range of compact scales, bench scales, floor scales, load cells, weigh modules and truck scales from which customer can choose the right weighing device.

Our safe weighing terminals provide the functionality they need, from manual basic weighing applications to semi- or fully automated process control, while standard communication interfaces provide unmatched integration with their process environment.

In addition to all these, customer can accelerate their workflows with the flexibility of using mobile batteries.

Consistent dosing, filling and mixing processes are the key to sustainable and high product quality.

When choosing the right weighing equipment to be used in hazardous areas, the appropriate method for the correct classification and protection class should be considered.

Using safe weighing devices keeps your product quality at the highest level by providing accurate and reliable weighing results with the highest levels of protection.

As the METTLER TOLEDO Turkey sales and service team, we would like to state that we are ready when the customer want to exchange information in all processes, from choosing the right equipment to all maintenance operations that must be done throughout its lifecycle.

No matter where in the world user are operating under any regulation, our solutions are designed and tested in accordance with IECEX, ATEX, FM and Local standards or regulations and are approved worldwide for maximum safety of their processes.

Weighing System Configuration in Hazardous Area Zone 1/ 21, Division 1[/caption]

At METTLER TOLEDO, we offer a wide range of compact scales, bench scales, floor scales, load cells, weigh modules and truck scales from which customer can choose the right weighing device.

Our safe weighing terminals provide the functionality they need, from manual basic weighing applications to semi- or fully automated process control, while standard communication interfaces provide unmatched integration with their process environment.

In addition to all these, customer can accelerate their workflows with the flexibility of using mobile batteries.

Consistent dosing, filling and mixing processes are the key to sustainable and high product quality.

When choosing the right weighing equipment to be used in hazardous areas, the appropriate method for the correct classification and protection class should be considered.

Using safe weighing devices keeps your product quality at the highest level by providing accurate and reliable weighing results with the highest levels of protection.

As the METTLER TOLEDO Turkey sales and service team, we would like to state that we are ready when the customer want to exchange information in all processes, from choosing the right equipment to all maintenance operations that must be done throughout its lifecycle.

No matter where in the world user are operating under any regulation, our solutions are designed and tested in accordance with IECEX, ATEX, FM and Local standards or regulations and are approved worldwide for maximum safety of their processes.

Hazardous Area Classification According to IEC EN 60079-10[/caption]

Weighing equipment for hazardous areas is designed for safe use in such environments and it is essential that its function and integrity be maintained through out its lifetime from installation. The IEC 60079 series of standards on the use of electrical equipment in hazardous areas covers two important areas:

• IEC 60079-14: Design, Selection and Installation of Equipment

• IEC 60079-17: Regular Inspection and Maintenance of Equipment

These international standards form the basis for national occupational safety and hazardous area regulations.

Hazardous Area Classification According to IEC EN 60079-10[/caption]

Weighing equipment for hazardous areas is designed for safe use in such environments and it is essential that its function and integrity be maintained through out its lifetime from installation. The IEC 60079 series of standards on the use of electrical equipment in hazardous areas covers two important areas:

• IEC 60079-14: Design, Selection and Installation of Equipment

• IEC 60079-17: Regular Inspection and Maintenance of Equipment

These international standards form the basis for national occupational safety and hazardous area regulations.

As METTLER TOLEDO, we are at the customer side with our expertise in compliance with all requirements of the relevant standards, documentation, correct data storage, data integration, correct use of equipment, and regular inspection and maintenance.

As METTLER TOLEDO, we are at the customer side with our expertise in compliance with all requirements of the relevant standards, documentation, correct data storage, data integration, correct use of equipment, and regular inspection and maintenance.