IATF Certification for Silicone Manufacturing: WACKER is Now a Direct Supplier to the Automotive Industry

WACKER, a Munich-based chemical company, is moving ahead with its silicone business specialization in the field of electromobility. Parts of its silicone production have now been certified to the IATF 16949 automotive standard.

As a result, WACKER can now provide silicone products to automakers and OEMs that have been developed and manufactured using IATF-certified processes. The certificates are valid for certain company parts manufactured in Burghausen, Germany, and Zhangjiagang, China. The certification included corporate functions that support and control the manufacturing process.

[caption id="attachment_135024" align="aligncenter" width="696"]

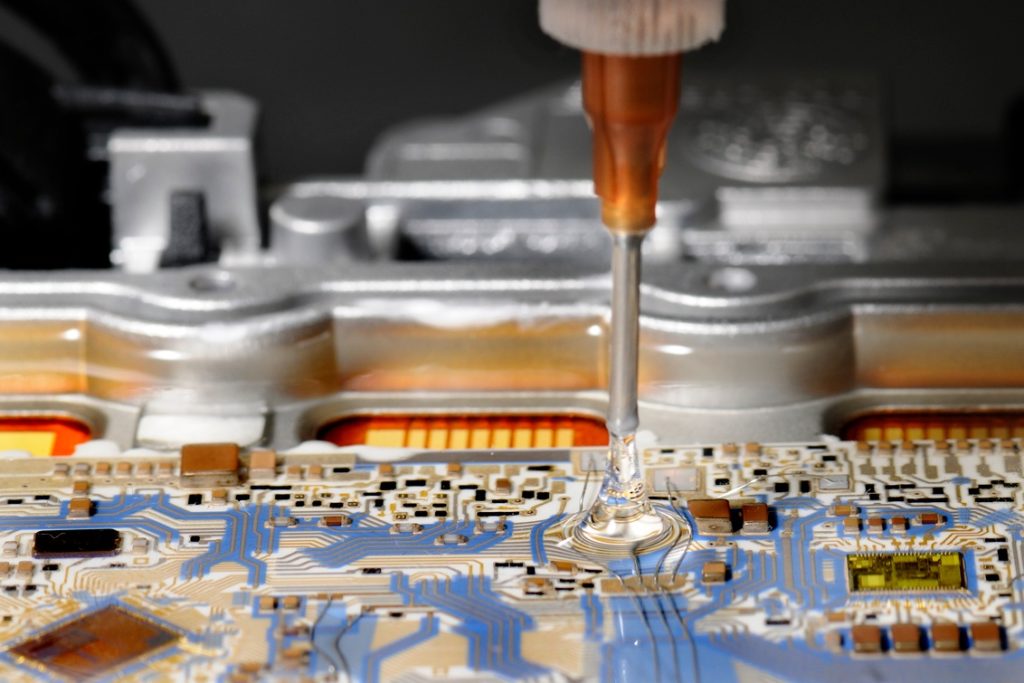

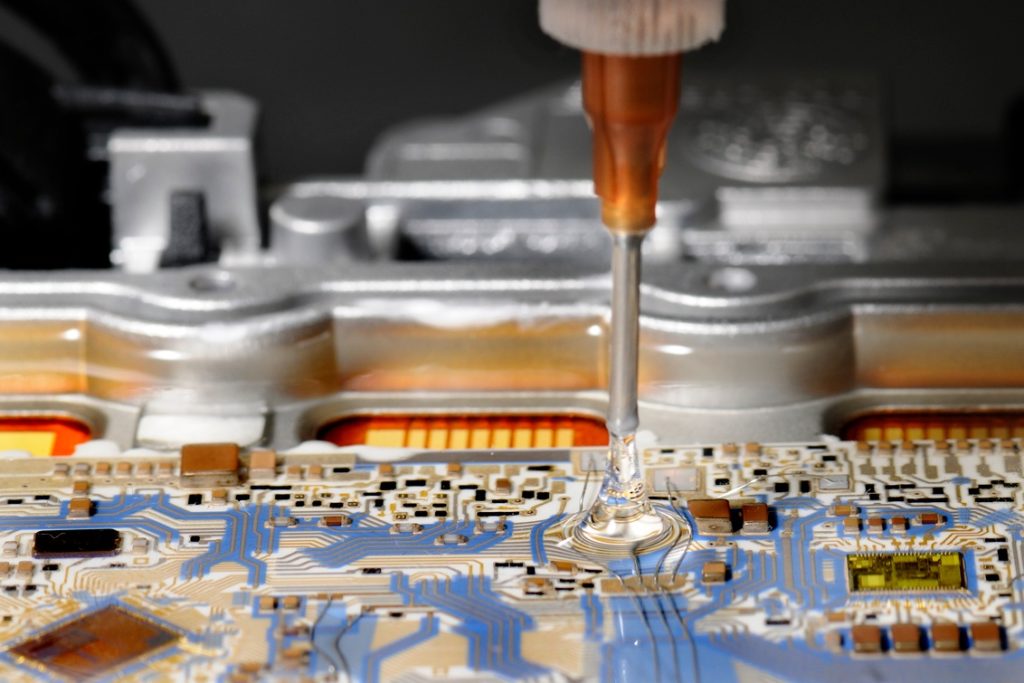

Thermally conductive silicone gap fillers from WACKER optimize the thermal transport between an electronic circuit that becomes hot during operation and the heat sink. With the successful certification according to standard IATF 16949, the Munich-based chemical Group WACKER can directly supply automobile manufacturers as well as system and module suppliers. (Photo: WACKER)[/caption]

TÜV NORD CERT certifies that WACKER's quality management system fully complies with the requirements of the IATF 16949 standard. The certified manufacturing plants create two-component silicone rubber formulations that cure at room temperature via an addition reaction to form silicone elastomers.

They are heat-conducting gap fillers, silicone adhesives, and potting compounds that go by the names SEMICOSIL®, ELASTOSIL®, and WACKER SilGel®, among others.

Silicones have become a necessary component of electric vehicles. Silicone rubber potting compounds effectively protect onboard and control electronics from vibrations, moisture, and dirt. Thermal gap fillers help to improve the thermal management of electric vehicle batteries and power electronics, which generate a lot of heat during operation or charging and must be cooled reliably.

[caption id="attachment_135023" align="aligncenter" width="696"]

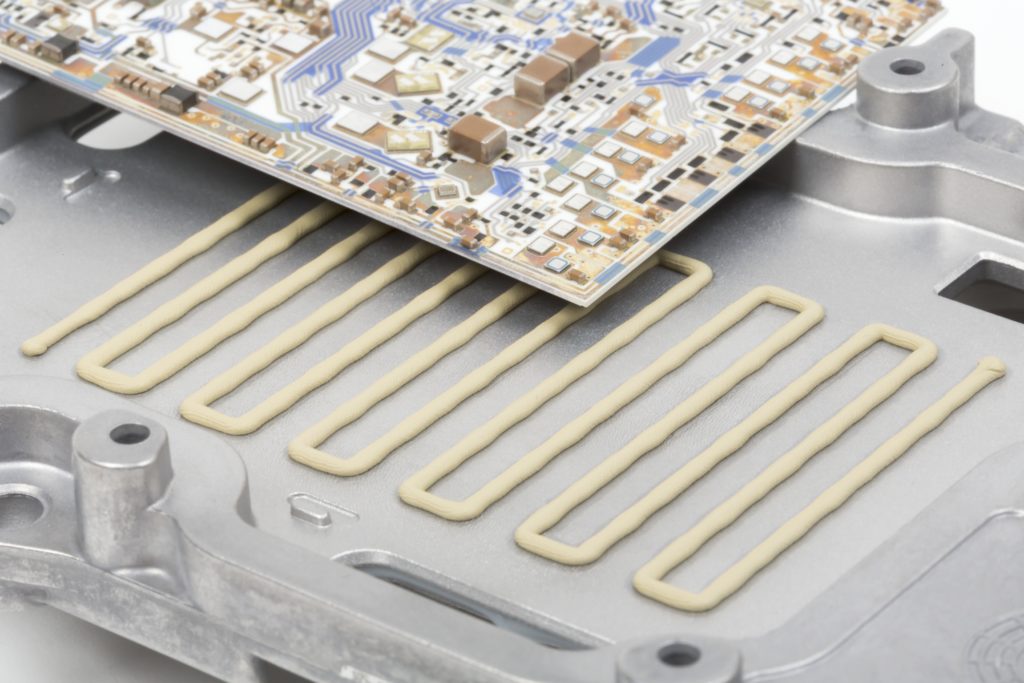

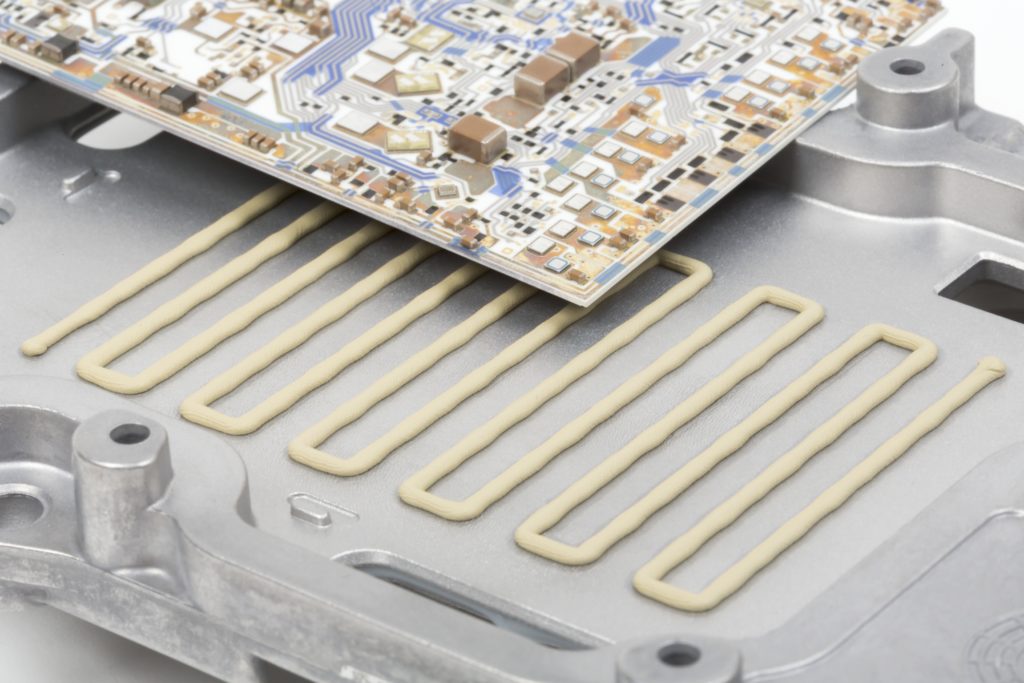

WACKER’s silicone gels were especially developed for manufacturers of electronic components. Particular products can be cured at room tempera-ture or elevated temperatures. Gels with rapid curing through UV-radiation are also available. (Photo: WACKER)[/caption]

With the electromobility revolution, WACKER is chalking up strong demand for such silicones.

“The automotive industry is a key industry and will remain so, not only for Germany,” says Robert Gnann, president of WACKER SILICONES. “Demand for high-performance materials, which also include our silicones, is growing steadily. For WACKER, it is just the right time to perform IATF certification. With our innovative silicone portfolio, we will boost the automotive industry in achieving its goals of productivity, efficiency and quality.”

IATF 16949 was developed in 2016 by leading European and North American automobile manufacturers. It combines the core require-ments and quality management standards agreed on by the auto industry.

The goal is to minimize quality risks and continually improve reliability of production and the supply chain. Certification according to IATF 16949 is the most important condition for direct cooperation between the supplier and automobile manufacturer.

With the successful certification, WACKER can now supply silicone products directly to car manufacturers and their system and module suppliers.

“Our customers require not only high-quality products, but also a reliable partner who is capable of offering individual tailor-made solutions that fully meet the industry’s strict guidelines and processes,” says Duke Cho, who heads both the subsidiary Wacker Chemicals Korea and the business unit Industrial Solutions of the WACKER SILICONES business division:

“The certification demonstrates that we are fully capable of meeting these challenges and requirements in production and quality management. Our business in the field of electromobility will profit significantly from this.”

Potting Compounds, Silicone Adhesives and Gap Fillers for E-mobility Silicone elastomers are critical for meeting future automotive engineering technical demands, particularly in the field of electromobility.

WACKER silicones protect sensitive electronics and aid thermal management in electric motors, power electronics, displays, fuel cells, batteries, and sensors. As a result, they offer a dependable, cost-effective solution for supporting key industry trends like car electrification and connectivity, as well as autonomous driving.

Thermally conductive silicones from WACKER are preferably used for thermal management in electric cars, since they effectively dissipate the heat. They maintain the same material properties even at temperatures between -50 °C and +180°C – and up to +230°C for special grades.

Depending on the design, thermal gap fillers, silicone encapsulants and adhesives as well as thermally conductive pastes are suitable for efficient cooling of the component. Potting compounds and gap fillers from WACKER are used among other things for thermal connection between the battery modules and heat-sink system or for protection and for cooling the power electronics.

Source

Thermally conductive silicone gap fillers from WACKER optimize the thermal transport between an electronic circuit that becomes hot during operation and the heat sink. With the successful certification according to standard IATF 16949, the Munich-based chemical Group WACKER can directly supply automobile manufacturers as well as system and module suppliers. (Photo: WACKER)[/caption]

TÜV NORD CERT certifies that WACKER's quality management system fully complies with the requirements of the IATF 16949 standard. The certified manufacturing plants create two-component silicone rubber formulations that cure at room temperature via an addition reaction to form silicone elastomers.

They are heat-conducting gap fillers, silicone adhesives, and potting compounds that go by the names SEMICOSIL®, ELASTOSIL®, and WACKER SilGel®, among others.

Silicones have become a necessary component of electric vehicles. Silicone rubber potting compounds effectively protect onboard and control electronics from vibrations, moisture, and dirt. Thermal gap fillers help to improve the thermal management of electric vehicle batteries and power electronics, which generate a lot of heat during operation or charging and must be cooled reliably.

[caption id="attachment_135023" align="aligncenter" width="696"]

Thermally conductive silicone gap fillers from WACKER optimize the thermal transport between an electronic circuit that becomes hot during operation and the heat sink. With the successful certification according to standard IATF 16949, the Munich-based chemical Group WACKER can directly supply automobile manufacturers as well as system and module suppliers. (Photo: WACKER)[/caption]

TÜV NORD CERT certifies that WACKER's quality management system fully complies with the requirements of the IATF 16949 standard. The certified manufacturing plants create two-component silicone rubber formulations that cure at room temperature via an addition reaction to form silicone elastomers.

They are heat-conducting gap fillers, silicone adhesives, and potting compounds that go by the names SEMICOSIL®, ELASTOSIL®, and WACKER SilGel®, among others.

Silicones have become a necessary component of electric vehicles. Silicone rubber potting compounds effectively protect onboard and control electronics from vibrations, moisture, and dirt. Thermal gap fillers help to improve the thermal management of electric vehicle batteries and power electronics, which generate a lot of heat during operation or charging and must be cooled reliably.

[caption id="attachment_135023" align="aligncenter" width="696"] WACKER’s silicone gels were especially developed for manufacturers of electronic components. Particular products can be cured at room tempera-ture or elevated temperatures. Gels with rapid curing through UV-radiation are also available. (Photo: WACKER)[/caption]

With the electromobility revolution, WACKER is chalking up strong demand for such silicones.

“The automotive industry is a key industry and will remain so, not only for Germany,” says Robert Gnann, president of WACKER SILICONES. “Demand for high-performance materials, which also include our silicones, is growing steadily. For WACKER, it is just the right time to perform IATF certification. With our innovative silicone portfolio, we will boost the automotive industry in achieving its goals of productivity, efficiency and quality.”

IATF 16949 was developed in 2016 by leading European and North American automobile manufacturers. It combines the core require-ments and quality management standards agreed on by the auto industry.

The goal is to minimize quality risks and continually improve reliability of production and the supply chain. Certification according to IATF 16949 is the most important condition for direct cooperation between the supplier and automobile manufacturer.

With the successful certification, WACKER can now supply silicone products directly to car manufacturers and their system and module suppliers.

“Our customers require not only high-quality products, but also a reliable partner who is capable of offering individual tailor-made solutions that fully meet the industry’s strict guidelines and processes,” says Duke Cho, who heads both the subsidiary Wacker Chemicals Korea and the business unit Industrial Solutions of the WACKER SILICONES business division:

“The certification demonstrates that we are fully capable of meeting these challenges and requirements in production and quality management. Our business in the field of electromobility will profit significantly from this.”

Potting Compounds, Silicone Adhesives and Gap Fillers for E-mobility Silicone elastomers are critical for meeting future automotive engineering technical demands, particularly in the field of electromobility.

WACKER silicones protect sensitive electronics and aid thermal management in electric motors, power electronics, displays, fuel cells, batteries, and sensors. As a result, they offer a dependable, cost-effective solution for supporting key industry trends like car electrification and connectivity, as well as autonomous driving.

Thermally conductive silicones from WACKER are preferably used for thermal management in electric cars, since they effectively dissipate the heat. They maintain the same material properties even at temperatures between -50 °C and +180°C – and up to +230°C for special grades.

Depending on the design, thermal gap fillers, silicone encapsulants and adhesives as well as thermally conductive pastes are suitable for efficient cooling of the component. Potting compounds and gap fillers from WACKER are used among other things for thermal connection between the battery modules and heat-sink system or for protection and for cooling the power electronics.

Source

WACKER’s silicone gels were especially developed for manufacturers of electronic components. Particular products can be cured at room tempera-ture or elevated temperatures. Gels with rapid curing through UV-radiation are also available. (Photo: WACKER)[/caption]

With the electromobility revolution, WACKER is chalking up strong demand for such silicones.

“The automotive industry is a key industry and will remain so, not only for Germany,” says Robert Gnann, president of WACKER SILICONES. “Demand for high-performance materials, which also include our silicones, is growing steadily. For WACKER, it is just the right time to perform IATF certification. With our innovative silicone portfolio, we will boost the automotive industry in achieving its goals of productivity, efficiency and quality.”

IATF 16949 was developed in 2016 by leading European and North American automobile manufacturers. It combines the core require-ments and quality management standards agreed on by the auto industry.

The goal is to minimize quality risks and continually improve reliability of production and the supply chain. Certification according to IATF 16949 is the most important condition for direct cooperation between the supplier and automobile manufacturer.

With the successful certification, WACKER can now supply silicone products directly to car manufacturers and their system and module suppliers.

“Our customers require not only high-quality products, but also a reliable partner who is capable of offering individual tailor-made solutions that fully meet the industry’s strict guidelines and processes,” says Duke Cho, who heads both the subsidiary Wacker Chemicals Korea and the business unit Industrial Solutions of the WACKER SILICONES business division:

“The certification demonstrates that we are fully capable of meeting these challenges and requirements in production and quality management. Our business in the field of electromobility will profit significantly from this.”

Potting Compounds, Silicone Adhesives and Gap Fillers for E-mobility Silicone elastomers are critical for meeting future automotive engineering technical demands, particularly in the field of electromobility.

WACKER silicones protect sensitive electronics and aid thermal management in electric motors, power electronics, displays, fuel cells, batteries, and sensors. As a result, they offer a dependable, cost-effective solution for supporting key industry trends like car electrification and connectivity, as well as autonomous driving.

Thermally conductive silicones from WACKER are preferably used for thermal management in electric cars, since they effectively dissipate the heat. They maintain the same material properties even at temperatures between -50 °C and +180°C – and up to +230°C for special grades.

Depending on the design, thermal gap fillers, silicone encapsulants and adhesives as well as thermally conductive pastes are suitable for efficient cooling of the component. Potting compounds and gap fillers from WACKER are used among other things for thermal connection between the battery modules and heat-sink system or for protection and for cooling the power electronics.

Source