Viscoelastic (Memory) Foam Systems

The Definition of Viscoelastic and Viscoelastic Polyurethane Foam

The definition of viscoelastic is having the physical properties that exhibit both viscous and elastic characteristics when undergoing deformation. When a stress is applied on a viscous material, it deforms and when the load is removed, the material “forgets” its original form and remains in the deformed state.

On the other hand, when a stress is applied on an elastic material, it deforms and when the load is removed, the material “remembers” its original form and returns instantaneously to its original state. A viscoelastic material has both of these properties, when a stress is applied and then removed, it returns to its original state with a time-dependent behaviour. And a viscoelastic material is also temperature sensitive. Ambient temperature affects its behaviour depending on its glass transition temperature.

Today viscoelastic property is most common for polyurethane foams. Viscoelastic polyurethane foam is capable of redistributing the pressure applied on it. When the pressure is removed, the foam slowly returns to its initial state. Due to this gradual recovery or springback, it is also called memory foam, slow recovery foam or low resilience foam. This type of polyurethane foam easily conforms to the shape of the human body, softening with the body heat, it redistributes the body weight giving extra comfort and relaxation feeling.

The Invention and Development of Viscoelastic Polyurethane Foam

Viscoelastic polyurethane foam was invented in 1966 by NASA Research Center to be used in the aircraft seatings and spacesuits cushions. Owing to the properties of viscoelastic foam, it redistributes the G-force over the pilot’s and astronaut’s body.

After the invention, in 1980’s NASA disclosed viscoelastic polyurethane foam to the public. Then it easily found use in medical applications. People confined to wheelschairs and beds benefit from the pressure redistribution property of viscoelastic foam that prevents the pressure sores and makes the blood circulation better.

Then in 1991, Swedish bed manufacturer Tempur became the first company that commercialized viscoelastic polyurethane foam in mattresses.

Today, besides the medical purposes, viscoelastic polyurethane foam is used in pillows, mattresses, insoles, helmet liners, office chairs and vehicle seatings.

[caption id="attachment_134129" align="aligncenter" width="333"]

Figure 1. The slow recovery of viscoelastic polyurethane foam.[/caption]

The Physical Properties of Viscoelastic Polyurethane Foam

In viscoelastic polyurethane foam, there are four different effects working together to give a combined effect. These are network effect, relaxation effect, pneumatic effect and adhesive effect. While the network effect is responsible for restoring the initial shape of the foam, the remaining three effects compensate this resilient force to achieve slow recovery of the viscoelastic foams.

Network Effect: This is the main restoring force of the foam which enables it to recover its initial form. Due to this effect, all flexible polyurethane foams tend to spring back after the stress is removed.

Relaxation Effect: This is the chemical side of the slow recovery of the foam. The glass transition temperatures (Tg) of the viscoelastic foams are quite higher than the standard high resilient foams. Owing to this high glass transition temperature, some network segments of the foam are hard/frozen at room temperature and restricted in their mobility. This reduces the resiliency of the foam and lead to time retarded behavior. The polymeric chain lengths, cross-linking density, plasticizer concentrations determine the glass transition temperature of the foam. The closer the glass transition temperature

to the room temperature, the slower recovery of the foam.

Pneumatic Effect: This is a part of the physical side of the slow recovery of the foam. It is about the openness of the foam cells and the closer and finer the cells are, the more time needed for air to flow in and out of the foam, causing slow recovery.

Adhesive Effect: This is another part of the physical side of the slow recovery of the foam. It is about the stickiness of the foam surfaces and the stickier the surfaces are, the more time needed for the foam to restore, causing slow recovery. And the stickiness of the foam is more, if the temperature of the foam is close to its glass transition temperature.

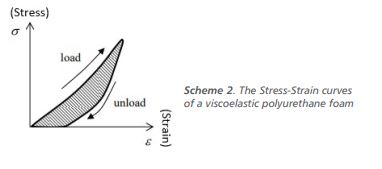

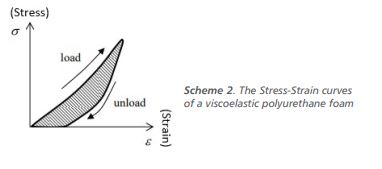

Owing to the combined effect of those above, viscoelastic polyurethane foams have the property of memory with a low resilience, applying less force to spring back (strain) against an applied force (stress) comparing to the standard polyurethane foams. As seen below, the stress-strain curves of a viscoelastic polyurethane foam are different while those curves would coincide for a standard polyurethane foam.

The Structure of Viscoelastic Polyurethane Foam

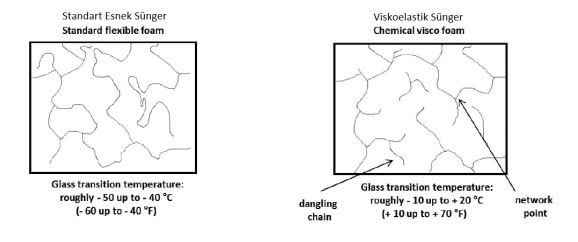

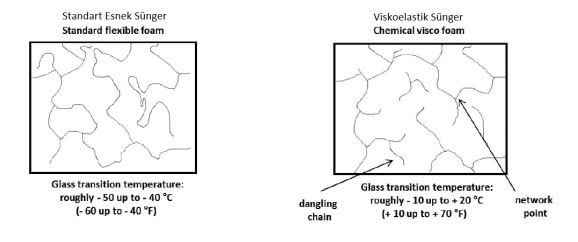

In viscoelastic polyurethane foam, there are different kinds of polyols having different characteristics. Using low OH, high MW polyols result in softer and resilient foams, while using high OH, low MW polyols result in harder, more cross-linked and slow recovery foams. Using high OH, low MW polyols leaves more dangling chains in the foam structure and shifts the glass transition temperature to higher values.

Producing the polyurethane foams at high isocyanate index values, increasing the aromaticity in the structure, shifts the glass transition temperature to higher values. If the glass transition temperature is high and close to the room temperature, the recovery of viscoelastic foam is slower. If the ambient temperature increases, the firmness of viscoelastic foam decreases and the recovery gets faster.

[caption id="attachment_134131" align="aligncenter" width="578"]

Figure 3. The structures of standard flexible foam and viscoelastic polyurethane foam.[/caption]

In addition to the polyols mentioned above, sometimes plasticizers or flame retardants can be added to the formulation of viscoelastic foams depending on the customers’ needs. Generally viscoelastic polyurethane foams are produced at higher densities than standard polyurethane foams to increase their comfort and durability.

The Usage and Benefits of Viscoelastic Polyurethane Foam

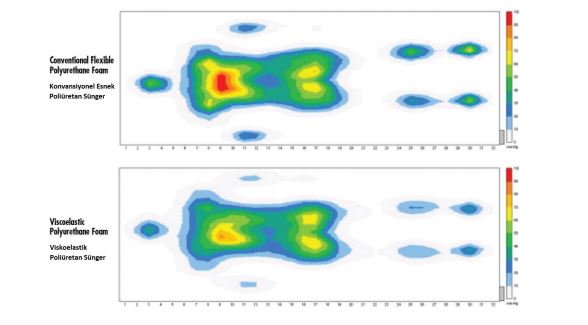

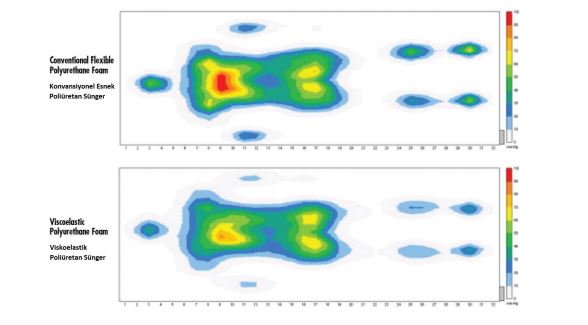

[caption id="attachment_134132" align="aligncenter" width="588"]

Figure 4. The pressure map of a human body on the viscoelastic foam bed comparing to the conventional

polyurethane foam bed.[/caption]

As can be seen in Scheme 4, the pressure distribution of human body on a viscoelastic foam bed is much better than the one on a standard foam bed. This pressure reducing property of viscoelastic foam is especially beneficial to prevent the pressure sores and for uninhibited blood circulation.

Besides their comfort and medical applications, viscoelastic polyurethane foams are also used as shock absorbing, vibration damping or sound absorbing materials.

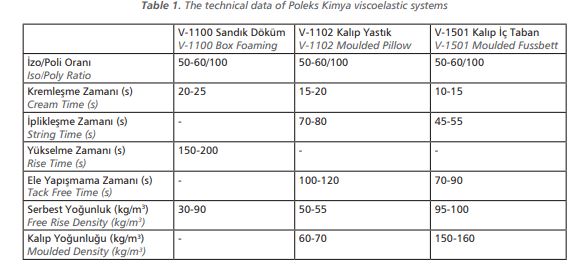

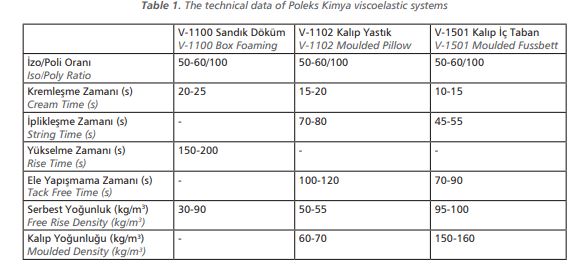

Poleks Kimya viscoelastic systems are manufactured at different densities, hardness levels and recovery times for different sectors. Low density, soft products that spring back slowly are available for pillows and medical pillows while there are higher density, harder products that spring back faster for insoles. In terms of production technology, viscoelastic pillows and insoles are produced by moulded foaming, viscoelastic mattresses are produced by slabstock or box foaming.

Below are the technical specifications of Poleks Kimya viscoelastic systems.

The advantages of Poleks Kimya viscoelastic foam systems are as follows:

• Smooth skin and uniform cell structure,

• Effective flowability and filling in large moulds,

• Wide range of iso/poly ratio, hardness and recovery time,

• Fast curing and short de-moulding time,

• Long aging time.

References

Hager et al., Viscoelastic Polyurethane Foams, Bayer Material Science LLC, US 2013/0289150A1, 2013.

M. Krebs and R. Hubel, The Adjustment of Physical Properties of Viscoelastic Foam - the Role of Different Raw Materials, Evonik Nutrition & Care GmbH, American Chemistry Council, 2016.

In-Touch Publication, Viscoelastic (Memory) Foam, Polyurethane Foam Association, Vol.11, No:1, 2016.

Yücel Aktay

Chemical Engineer M.Sc.

R&D and Technical Support Specialist

Poleks Kimya San. ve Tic. A.Ş.

Dr. Murat Baranak

Chemical Engineer

R&D and Quality Control Manager

Poleks Kimya San. ve Tic. A.Ş.

Figure 1. The slow recovery of viscoelastic polyurethane foam.[/caption]

Figure 1. The slow recovery of viscoelastic polyurethane foam.[/caption]

Figure 3. The structures of standard flexible foam and viscoelastic polyurethane foam.[/caption]

In addition to the polyols mentioned above, sometimes plasticizers or flame retardants can be added to the formulation of viscoelastic foams depending on the customers’ needs. Generally viscoelastic polyurethane foams are produced at higher densities than standard polyurethane foams to increase their comfort and durability.

Figure 3. The structures of standard flexible foam and viscoelastic polyurethane foam.[/caption]

In addition to the polyols mentioned above, sometimes plasticizers or flame retardants can be added to the formulation of viscoelastic foams depending on the customers’ needs. Generally viscoelastic polyurethane foams are produced at higher densities than standard polyurethane foams to increase their comfort and durability.

Figure 4. The pressure map of a human body on the viscoelastic foam bed comparing to the conventional

Figure 4. The pressure map of a human body on the viscoelastic foam bed comparing to the conventional The advantages of Poleks Kimya viscoelastic foam systems are as follows:

• Smooth skin and uniform cell structure,

• Effective flowability and filling in large moulds,

• Wide range of iso/poly ratio, hardness and recovery time,

• Fast curing and short de-moulding time,

• Long aging time.

References

Hager et al., Viscoelastic Polyurethane Foams, Bayer Material Science LLC, US 2013/0289150A1, 2013.

M. Krebs and R. Hubel, The Adjustment of Physical Properties of Viscoelastic Foam - the Role of Different Raw Materials, Evonik Nutrition & Care GmbH, American Chemistry Council, 2016.

In-Touch Publication, Viscoelastic (Memory) Foam, Polyurethane Foam Association, Vol.11, No:1, 2016.

Yücel Aktay

Chemical Engineer M.Sc.

R&D and Technical Support Specialist

Poleks Kimya San. ve Tic. A.Ş.

Dr. Murat Baranak

Chemical Engineer

R&D and Quality Control Manager

Poleks Kimya San. ve Tic. A.Ş.

The advantages of Poleks Kimya viscoelastic foam systems are as follows:

• Smooth skin and uniform cell structure,

• Effective flowability and filling in large moulds,

• Wide range of iso/poly ratio, hardness and recovery time,

• Fast curing and short de-moulding time,

• Long aging time.

References

Hager et al., Viscoelastic Polyurethane Foams, Bayer Material Science LLC, US 2013/0289150A1, 2013.

M. Krebs and R. Hubel, The Adjustment of Physical Properties of Viscoelastic Foam - the Role of Different Raw Materials, Evonik Nutrition & Care GmbH, American Chemistry Council, 2016.

In-Touch Publication, Viscoelastic (Memory) Foam, Polyurethane Foam Association, Vol.11, No:1, 2016.

Yücel Aktay

Chemical Engineer M.Sc.

R&D and Technical Support Specialist

Poleks Kimya San. ve Tic. A.Ş.

Dr. Murat Baranak

Chemical Engineer

R&D and Quality Control Manager

Poleks Kimya San. ve Tic. A.Ş.