Use of Lightweight Filling Materials to Increase Thermal Insulation

It is very well know that in most countries, energy use in the building sector represents about one third of the total energy consumption. Moreover, in developing countries the residential building sector accounts for more than half of the electricity consumption. The economic growth is expected to boost residential demand for electricity, such as electric lighting, air conditioning in order to keep the comfort properties.

For such reason, the energy consumption for residential shows an increasing trend worldwide and is of the key concerns over the world. In addition increasing electricity demand, increasing energy, costs and pollution levels there is real concern with the quality of indoor air when using of heaters or air-conditioners equipment. Moreover, for developed and developing areas it is known the heat island effect (urbanized areas that experience higher temperatures than outlying areas) has a become serious problem.

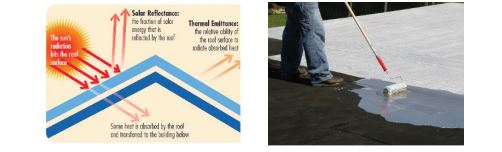

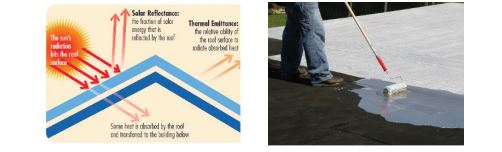

In construction industry, different kind of systems are getting traction for improving the thermal insulation properties of the buildings. From one side, it is already a megatrend in some countries the use of elastomeric coatings for roofing applications. Cool roof coatings are white or special reflective pigments that reflect sunlight. These coatings are like very thick paints that can protect the roof surface from ultraviolet (UV) light and chemical damage, and some offer water protection and restorative features.

Products are available for most roof types. applications improving some comfort properties like reflectivity (roof surface’s ability to reflect rays from the sun) and emissivity (is the ability of a roof to re-radiate any energy absorbed back to the sky), both key properties

for keeping the building comforts. A coating which maintains its solar reflectance and emittance will keep a building cooler and could lower energy costs by reflecting away heat from the sun. These properties (reflectance and emittance) can be enhanced by using engineered lightweight fillers like the closedcell expanded perlite.

In facades and interior the use of thermal insulation renders and plasters are well known as an effective mechanism for reducing the thermal conductivity, defined as rate at which heat transfers through a material with a given temperature gradient. The thermal conductivity of a material is a measure of its ability to conduct heat. By reducing the thermal conductivity it is expected a better insulation properties. There are several systems in the industry for reducing the thermal conductivity like for lightweight insulation mortars.

Light-weighting is an established global trend in a variety of industries and applications. It makes manufacturing products and living in our world easier. Conveniently, formulators can achieve light-weighting by adding specifically engineered fillers to their recipes. For building professionals lightweight fillers offer a great potential to support improvements in product properties, especially weight, and application procedures, which expands the comfort zone for people.

The utilization of lightweight fillers is already common in many construction applications like spackles, joint fillers, tile adhesives, plasters, renders, levelling compounds, thermal insulation mortars, whereas the required characteristic of the used lightweight filler may differ significantly, depending on the final formulation and performance of a product. One of the lightweight fillers materials with better insulation properties is the closed cell expanded perlite.

It is very well know the use of expanded perlite from decades for insulation purpose, but it is needed to differentiate between two different types of expanded perlite available in the market: the traditional open cell, and the engineering perlite based on closed-cell. When comparing both materials it can be checked how different both materials are.

The higher hermiticity, spherical morphology and higher compressive strength of closed cell expanded perlite leads to more suitable selection for insulation properties when comparing vs the traditional open cell expanded perlite (flake shape, not close structure and negligible strength). Moreover closed cell expanded perlite leads to lower water demand.

[caption id="attachment_139521" align="aligncenter" width="287"]

Lightweight Filler Base on Closed-Cell Expanded Perlite[/caption]

[caption id="attachment_139522" align="aligncenter" width="293"]

Traditional Open Cell Expanded Perlite[/caption]

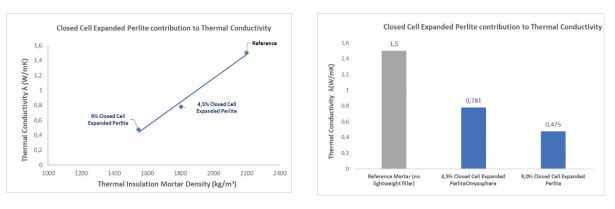

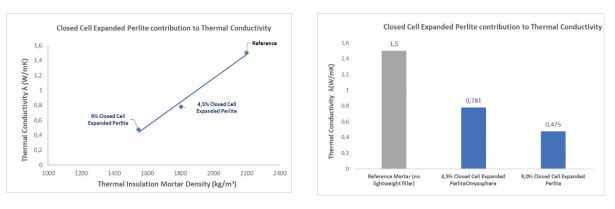

When measuring the thermal effectiveness of introducing lightweight fillers in insulation mortar, the thermal conductivity measurement can provide a clear indication of thermal insulation performance and it can be measured according to standard EN 12664. The principle of the determination of the thermal conductivity with the Guarded Hot Plate is to establish through homogeneous test sample in the form of plate with plane and parallel faces, a heat flow in stationary mode. The heat flux is obtained by measuring the power supplied to the hot element.

In testing carried out in several mixes containing lightweight fillers based on closed-cell expanded perlite it was confirmed the large impact on lambda (λ) reduction from λ=1,5 (W/mK) for reference non containing lightweight fillers down to λ= 0,47 (W/mK) when using 9% of Closed Cell expanded perlite (replacing the corresponding volume of sand when introducing the lightweight filler) meaning that thermal properties are significantly enhanced. Of course by increasing the dosage rate of the lightweight filler based on closed

cell expanded perlite it can be reduce more the lambda (λ) value. There are some insulation mortars with higher dosage rate of closed cell expanded perlite (up to 40%) leading to mortar density ~300kg/m3 and thermal conductivity λ=0,05 W/mK.

Summary

Comfort Properties (e.g. thermal insulation, solar reflectivity, emissivity) are a real global megatrend in construction industry and it is a real need to enhance the insulation properties of building by reducing energy consumption making more sustainable the future.

The use of lightweight fillers based on closed-cell expanded perlite, absolutely differentiated (higher hermiticity, sphericity and strength) vs the traditional expanded perlite, leads to lower thermal conductivity of final insulation coating and/ mortar allowing to improve the comfort properties of final systems and specifically improving the emissivity in roof coating applications and leading to significant thermal conductivity (Lambda, λ) reduction in several insulation mortars allowing to reduce the density of final system and increasing the yield (les material needed for covering one given area). It means, by using closed cell expanded perlite in these systems, comfort properties enhancement and light-weighting can be achieved matching two of the key real megatrends in construction industry.

Onur Eroğlu

Market Development Innovation Director

Omya

David Gonzalez

Global Application Manager Lightweight Fillers

Omya

In facades and interior the use of thermal insulation renders and plasters are well known as an effective mechanism for reducing the thermal conductivity, defined as rate at which heat transfers through a material with a given temperature gradient. The thermal conductivity of a material is a measure of its ability to conduct heat. By reducing the thermal conductivity it is expected a better insulation properties. There are several systems in the industry for reducing the thermal conductivity like for lightweight insulation mortars.

Light-weighting is an established global trend in a variety of industries and applications. It makes manufacturing products and living in our world easier. Conveniently, formulators can achieve light-weighting by adding specifically engineered fillers to their recipes. For building professionals lightweight fillers offer a great potential to support improvements in product properties, especially weight, and application procedures, which expands the comfort zone for people.

The utilization of lightweight fillers is already common in many construction applications like spackles, joint fillers, tile adhesives, plasters, renders, levelling compounds, thermal insulation mortars, whereas the required characteristic of the used lightweight filler may differ significantly, depending on the final formulation and performance of a product. One of the lightweight fillers materials with better insulation properties is the closed cell expanded perlite.

It is very well know the use of expanded perlite from decades for insulation purpose, but it is needed to differentiate between two different types of expanded perlite available in the market: the traditional open cell, and the engineering perlite based on closed-cell. When comparing both materials it can be checked how different both materials are.

The higher hermiticity, spherical morphology and higher compressive strength of closed cell expanded perlite leads to more suitable selection for insulation properties when comparing vs the traditional open cell expanded perlite (flake shape, not close structure and negligible strength). Moreover closed cell expanded perlite leads to lower water demand.

[caption id="attachment_139521" align="aligncenter" width="287"]

In facades and interior the use of thermal insulation renders and plasters are well known as an effective mechanism for reducing the thermal conductivity, defined as rate at which heat transfers through a material with a given temperature gradient. The thermal conductivity of a material is a measure of its ability to conduct heat. By reducing the thermal conductivity it is expected a better insulation properties. There are several systems in the industry for reducing the thermal conductivity like for lightweight insulation mortars.

Light-weighting is an established global trend in a variety of industries and applications. It makes manufacturing products and living in our world easier. Conveniently, formulators can achieve light-weighting by adding specifically engineered fillers to their recipes. For building professionals lightweight fillers offer a great potential to support improvements in product properties, especially weight, and application procedures, which expands the comfort zone for people.

The utilization of lightweight fillers is already common in many construction applications like spackles, joint fillers, tile adhesives, plasters, renders, levelling compounds, thermal insulation mortars, whereas the required characteristic of the used lightweight filler may differ significantly, depending on the final formulation and performance of a product. One of the lightweight fillers materials with better insulation properties is the closed cell expanded perlite.

It is very well know the use of expanded perlite from decades for insulation purpose, but it is needed to differentiate between two different types of expanded perlite available in the market: the traditional open cell, and the engineering perlite based on closed-cell. When comparing both materials it can be checked how different both materials are.

The higher hermiticity, spherical morphology and higher compressive strength of closed cell expanded perlite leads to more suitable selection for insulation properties when comparing vs the traditional open cell expanded perlite (flake shape, not close structure and negligible strength). Moreover closed cell expanded perlite leads to lower water demand.

[caption id="attachment_139521" align="aligncenter" width="287"] Lightweight Filler Base on Closed-Cell Expanded Perlite[/caption]

[caption id="attachment_139522" align="aligncenter" width="293"]

Lightweight Filler Base on Closed-Cell Expanded Perlite[/caption]

[caption id="attachment_139522" align="aligncenter" width="293"] Traditional Open Cell Expanded Perlite[/caption]

When measuring the thermal effectiveness of introducing lightweight fillers in insulation mortar, the thermal conductivity measurement can provide a clear indication of thermal insulation performance and it can be measured according to standard EN 12664. The principle of the determination of the thermal conductivity with the Guarded Hot Plate is to establish through homogeneous test sample in the form of plate with plane and parallel faces, a heat flow in stationary mode. The heat flux is obtained by measuring the power supplied to the hot element.

In testing carried out in several mixes containing lightweight fillers based on closed-cell expanded perlite it was confirmed the large impact on lambda (λ) reduction from λ=1,5 (W/mK) for reference non containing lightweight fillers down to λ= 0,47 (W/mK) when using 9% of Closed Cell expanded perlite (replacing the corresponding volume of sand when introducing the lightweight filler) meaning that thermal properties are significantly enhanced. Of course by increasing the dosage rate of the lightweight filler based on closed

cell expanded perlite it can be reduce more the lambda (λ) value. There are some insulation mortars with higher dosage rate of closed cell expanded perlite (up to 40%) leading to mortar density ~300kg/m3 and thermal conductivity λ=0,05 W/mK.

Traditional Open Cell Expanded Perlite[/caption]

When measuring the thermal effectiveness of introducing lightweight fillers in insulation mortar, the thermal conductivity measurement can provide a clear indication of thermal insulation performance and it can be measured according to standard EN 12664. The principle of the determination of the thermal conductivity with the Guarded Hot Plate is to establish through homogeneous test sample in the form of plate with plane and parallel faces, a heat flow in stationary mode. The heat flux is obtained by measuring the power supplied to the hot element.

In testing carried out in several mixes containing lightweight fillers based on closed-cell expanded perlite it was confirmed the large impact on lambda (λ) reduction from λ=1,5 (W/mK) for reference non containing lightweight fillers down to λ= 0,47 (W/mK) when using 9% of Closed Cell expanded perlite (replacing the corresponding volume of sand when introducing the lightweight filler) meaning that thermal properties are significantly enhanced. Of course by increasing the dosage rate of the lightweight filler based on closed

cell expanded perlite it can be reduce more the lambda (λ) value. There are some insulation mortars with higher dosage rate of closed cell expanded perlite (up to 40%) leading to mortar density ~300kg/m3 and thermal conductivity λ=0,05 W/mK.