Use of Dendimeric Structures in UV Curing Systems

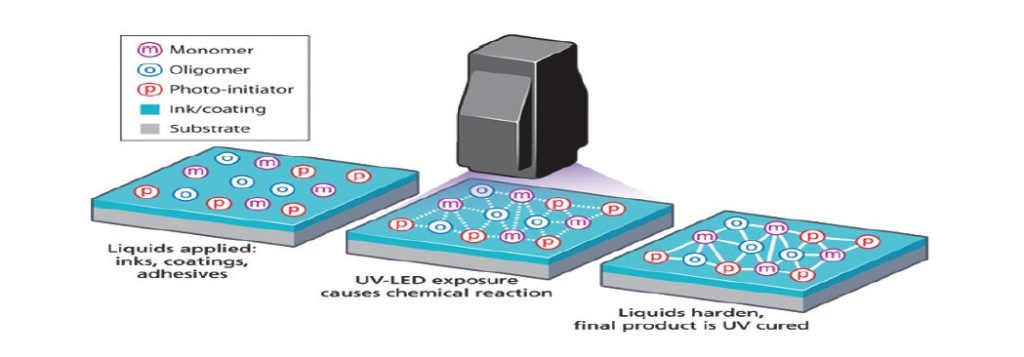

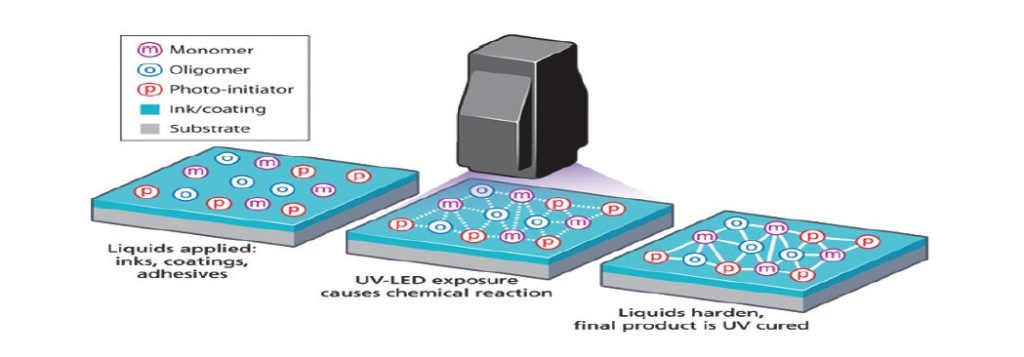

UV (Ultra Violet) curing is a system in which highintensity ultraviolet light is used for instant curing and drying of coatings and adhesives.

It can be adapted to UV curing coating, printing, embellishment and assembly of various products and materials. Curing with ultraviolet is a high speed process. The curing

process is carried out by polymerization rather than evaporation. The main advantage of UV curing is the speed it adds to production.

In addition to speeding up production, defects and errors are also drastically reduced as the time required for dust or another airborne object to come into contact with the material

is reduced.

Another obvious advantage of ultraviolet curing is that it allows less space to be allocated in the facilities for products that are about to be produced, since they do not have to wait for drying in production. This creates a good productivity throughout the entire production period.

On the other hand, UVcured adhesives have quickly become a substitute for two-component adhesives. This eliminates issues like solvent removal, ratio mixing, and potential lifetime.

Many diverse businesses employ ultraviolet-cured adhesives. These include the vehicle, beauty products, food, science, health care, education, and the arts [1]. The UV curable acrylic resin market is estimated to grow to 7.3 billion USD in 2026 from its current

value of 4.6 billion USD in 2021 [2,3].

[caption id="attachment_145936" align="aligncenter" width="673"]

Figure 1.

Figure 1. UV curing mechanism [4][/caption]

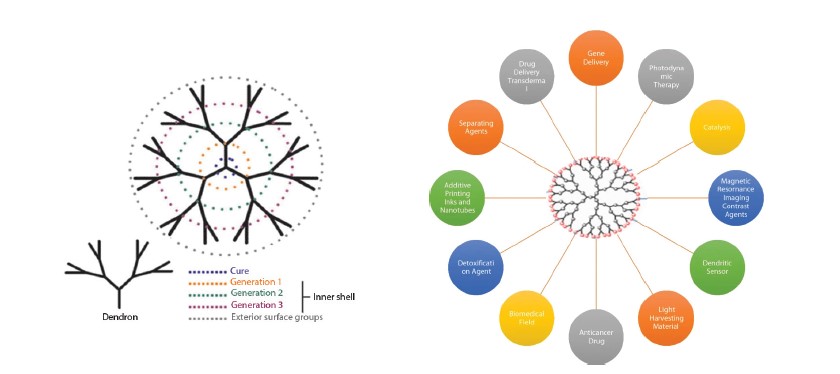

Dendritic polymers, also known as dendrimers, are the fourth most significant class of polymers after cross-linked, linear, and branched polymers. These are multi-branched, very smooth and three-dimensional macromolecules that grow from a multifunctional center.

They have particularly intriguing physical and chemical characteristics as a result of their structural characteristics. Dendrimers can develop exponentially by symmetrically adding new groups from the core, and the utilization of cores, end groups, and vacant spaces

determines how well these structures work [5].

Compared to ordinary polymers, dendrimers have a much reduced viscosity. The existence of multifunctional branches in a molecule causes a molecule’s molecular mass, complexity of structure, and intrinsic viscosity to increase dramatically, which causes a typical monomer to harden quickly. Using a standard monomer, it is exceedingly difficult to achieve

a viscosity-cure rate balance.

To speed up curing and enhance various optical features of the coated film, a new coating recipe with high UV-reactive nature but low viscosity can be utilized with a dendrimer.

Despite the above-mentioned notable advancements in the application of dendrimers in a variety of industries, further research is needed before dendrimers can be effectively used in UV curing [6].

[caption id="attachment_145937" align="aligncenter" width="840"]

Figure 2.

Figure 2. Dendrimers and their application[7,8][/caption]The Izel Kimya R&D Center conducts research on the production of UV-curable dendrimeric resins. By obtaining these resins and similar monomers, many areas such as teeth, coatings, paints and molds will be facilitated and will contribute to a sustainable economy.

References

1. http://www.rotalab.com/tr/urunler/yuzey-kurleme-sistemleri/ultraviyole-uv kurleme.html

2. https://www.grandviewresearch.com/industry-analysis/3d-printing-industry analysis#:~:text=The%20 global%203D%20printing%2market,21.5%20million%20units%20by%202030

3. https://www.turkchem.net/biyo-esasli-uv-ile-kurlenebilir-recineler.html

4. https://rimotec.nl/uv-curing/

5. Şener,Muhammed. Investigation Of Flotation Behavior Of PAMAM Dendrimers İn İndustrial Minerals.Doktora Tezi, İnönü Üniversitesi,2019.

6. Harmandar, K. Pamam türü dendrimerlere katalitik özellik kazandırılması, Yüksek Lisans Tezi, Yıldız Teknik Üniversitesi, 2016.

7. Gillani, S. S., Munawar, M. A., Khan, K. M., & Chaudhary, J. A. (2020). Synthesis, characterization and applications of poly-aliphatic amine dendrimers and dendrons. Journal of the Iranian Chemical Society, 17(11), 2717-2736.

8. Rwei, S. P., & Chen, J. D. (2012). Investigating the UV-curing performance for polyacrylated polymer in dendritic and regular conformation. Polymer bulletin, 68(2), 493-505.

Dr. Cemil Dizman

R&D Manager

İzel Kimya

Bahtiyar Yanar

R&D Researcher

İzel Kimya

Figure 1. UV curing mechanism [4][/caption]

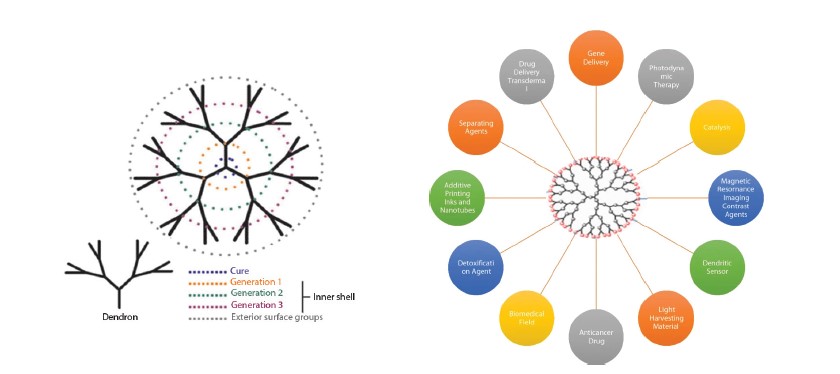

Dendritic polymers, also known as dendrimers, are the fourth most significant class of polymers after cross-linked, linear, and branched polymers. These are multi-branched, very smooth and three-dimensional macromolecules that grow from a multifunctional center.

They have particularly intriguing physical and chemical characteristics as a result of their structural characteristics. Dendrimers can develop exponentially by symmetrically adding new groups from the core, and the utilization of cores, end groups, and vacant spaces

determines how well these structures work [5].

Compared to ordinary polymers, dendrimers have a much reduced viscosity. The existence of multifunctional branches in a molecule causes a molecule’s molecular mass, complexity of structure, and intrinsic viscosity to increase dramatically, which causes a typical monomer to harden quickly. Using a standard monomer, it is exceedingly difficult to achieve

a viscosity-cure rate balance.

To speed up curing and enhance various optical features of the coated film, a new coating recipe with high UV-reactive nature but low viscosity can be utilized with a dendrimer.

Despite the above-mentioned notable advancements in the application of dendrimers in a variety of industries, further research is needed before dendrimers can be effectively used in UV curing [6].

[caption id="attachment_145937" align="aligncenter" width="840"]

Figure 1. UV curing mechanism [4][/caption]

Dendritic polymers, also known as dendrimers, are the fourth most significant class of polymers after cross-linked, linear, and branched polymers. These are multi-branched, very smooth and three-dimensional macromolecules that grow from a multifunctional center.

They have particularly intriguing physical and chemical characteristics as a result of their structural characteristics. Dendrimers can develop exponentially by symmetrically adding new groups from the core, and the utilization of cores, end groups, and vacant spaces

determines how well these structures work [5].

Compared to ordinary polymers, dendrimers have a much reduced viscosity. The existence of multifunctional branches in a molecule causes a molecule’s molecular mass, complexity of structure, and intrinsic viscosity to increase dramatically, which causes a typical monomer to harden quickly. Using a standard monomer, it is exceedingly difficult to achieve

a viscosity-cure rate balance.

To speed up curing and enhance various optical features of the coated film, a new coating recipe with high UV-reactive nature but low viscosity can be utilized with a dendrimer.

Despite the above-mentioned notable advancements in the application of dendrimers in a variety of industries, further research is needed before dendrimers can be effectively used in UV curing [6].

[caption id="attachment_145937" align="aligncenter" width="840"] Figure 2. Dendrimers and their application[7,8][/caption]The Izel Kimya R&D Center conducts research on the production of UV-curable dendrimeric resins. By obtaining these resins and similar monomers, many areas such as teeth, coatings, paints and molds will be facilitated and will contribute to a sustainable economy.

Figure 2. Dendrimers and their application[7,8][/caption]The Izel Kimya R&D Center conducts research on the production of UV-curable dendrimeric resins. By obtaining these resins and similar monomers, many areas such as teeth, coatings, paints and molds will be facilitated and will contribute to a sustainable economy.