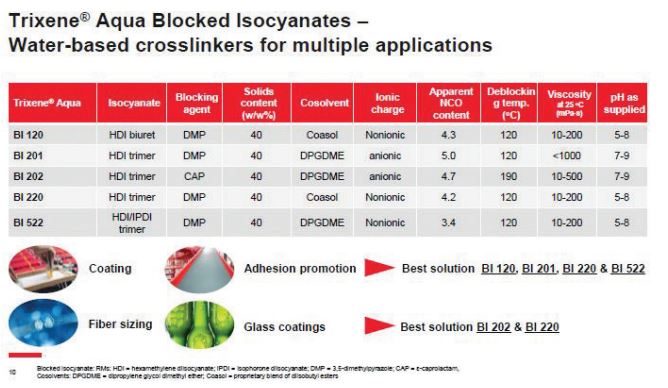

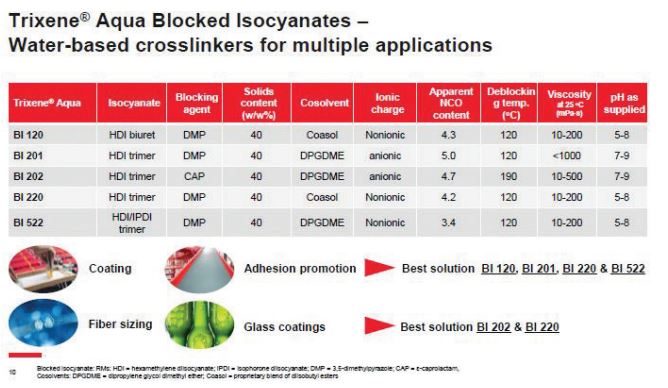

Trixene® Aqua BI From LANXESS - Water-Dispersible Blocked Polyisocyanates for Coatings and Adhesives

Trixene® Aqua series used as crosslinker and adhesion enhancer for industrial coatings and lacquers.

Trixene® Aqua grades offer a wide pH latitude including anionic, nonionic and cationic species with good formulation compatibility. Used in coatings and topcoats for flexible and rigid surfaces.

Improved Coating Performance and Protection

• Increases surface and interlayer adhesion performance.

• Improves chemical, impact and abrasion resistance.

• Provides durability according to weather conditions.

Formulation Benefits

• Applicable eg. spraying, dipping, roller/blade/curtain coating, brushing,

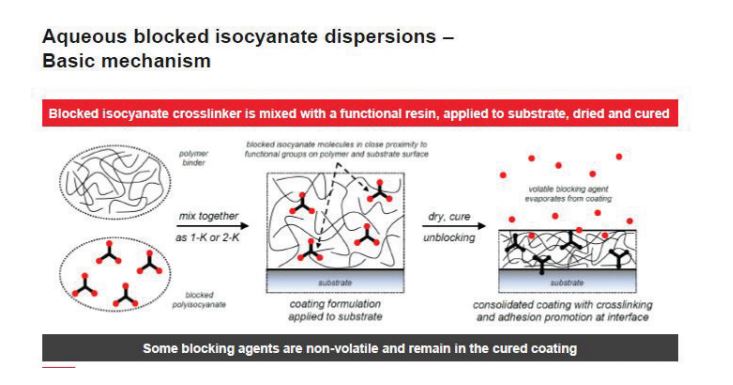

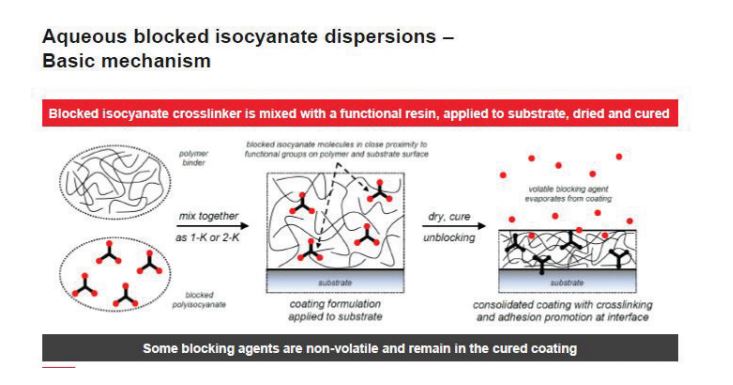

• Heat curing for controlled reactivity (no free isocyanate groups).

Trixene® Aqua acts as a crosslinking and bonding agent for a variety of flexible and rigid substrates.

Fiber Sizing

With Trixene® Aqua Crosslinkers used in glass fiber sizing,

• Improve integrity and reduce fluff formation.

• Improves compatibility with a resin matrix (eg resins such as PA, PES, Epoxy).

• Provides maximum efficiency with Lanxess’s Witcobond® Pud products.

• Increases higher glass/polymer matrix interaction and strength.

• Provides improved bond strength between reinforcement and polymer.

• It reduces the formation of solid residues in the process.

• Provides higher elasticity, impact and tensile strength.

Textile & Fabric

• Trixene® Aqua offers highly flexible coatings. Offers a variety of unblocking temperatures for textile and fabric coatings.

• It increases the tensile strength under severe conditions, in fiber impregnation oven coatings, to increase adhesion. It provides washing resistance.

• Trixene® Aqua blocked crosslinkers improve adhesion of fluorochemical and other aqueous finishes to natural and synthetic fabrics.

Adhesion enhancer for aqueous, fluorocarbon-based water repellents.

• 2K based on C8 (PFOA & PFOS) eliminates solvent applied finishes.

• Allows the transition to aqueous fluorochemicals based on “safer” C6 and C4 chemistry.

• Allows formulating 1K, covert cure C6/C4 systems with low or no VOC content.

• Non-ionic grades, eg. Trixene Aqua BI 220 provides a wide pH/formulation range.

• Apply to substrate (eg woven polyamide, polyester) by padding or roller.

• Dry at high temperatures (~150 °C, 3-5 minutes).

• Provides superior water, oil repellency, improved durability, dry cleaning resistance.

Coatings

• Improves adhesion to substrate and successive layers.

• Increases impact, scratch and chemical resistance on the coating surface.

• Provides excellent color retention.

Ece Okçu

C.A.S.E PU Sales Responsible

Kimsel

Ece Okçu

C.A.S.E PU Sales Responsible

Kimsel

Ece Okçu

C.A.S.E PU Sales Responsible

Kimsel