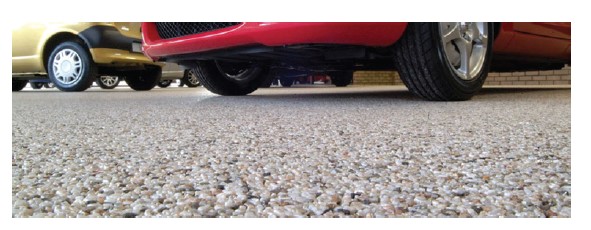

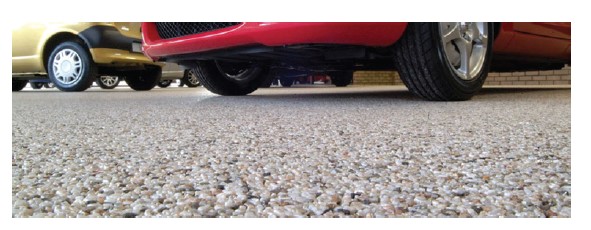

Picture 1. Parking area

Picture 2. Swimming pool

Picture 3. Indoor and outdoor examples

After presenting the application area mentioned above It would be useful to introduce the binding materials used in this system. The purpose of using these binders is to ensure that the stones are held together and not to be separated under environmental conditions. First, two-component epoxy materials were used in these systems. Due to the following problems of using the epoxy binders, for better performance the need for another types of binders have revealed. •Non-UV resistant and yellowing in light colored stone systems, •Breaking of stones due to hot-cold weather shocks or winter freezing. As in many other industries, the best equivalent materials to epoxy materials are polyurethanes. The polyurethane materials provide us; the desired hardness/elastic product designs, the aliphatic system to be resistant to UV/no yellowing and polymer materials with the breathable properties. Let us explain why polyurethane materials should be preferred in this application; Aliphatic polyurethane materials are UV resistant, they have not yellowing property. Since our aliphatic products do not contain aromatic parts due to their structure, they are not affected by UV rays and do not make yellowing. The main reason for the yellowing is that the aromatic structures interact with the UV light and turn into a yellow color structure. Aromatic compounds are composed of benzene and condensed benzene rings. In the light of this information, when we look at the MDI which is a polyurethane isocyanate compounds and epoxy, we will see that both structures contain aromatic sections. Therefore, for a non-yellowing structure, firstly our raw materials should not contain aromatic regions. In this sense, the polyurethane raw materials (polyol and isocyanates) should be in aliphatic structure. Considering that polyol groups are generally aliphatic, aliphatic isocyanates are listed below.

Therefore, for a non-yellowing structure, firstly our raw materials should not contain aromatic regions. In this sense, the polyurethane raw materials (polyol and isocyanates) should be in aliphatic structure. Considering that polyol groups are generally aliphatic, aliphatic isocyanates are listed below.

This adhesion performance and mechanical characteristic prevent the polyurethane flooring system from breaking as a result of the freezing (because of the water remaining between the stones) in winter and also in hot and cold passages in the final product.

Has better drainage performance.

The stone floor systems, which are expressed as water permeable ground, allow the water to be kept under the surface by using the structural gaps. This system has been used in areas like ways and on the pool sides, where water is unavoidable.

To design this system, it is possible to use different sized stones or different polymer materials as binders. The ability of the epoxy materials to wet the surface is not as good as polyurethane materials. Wetting the surface directly affects the adhesion performance.

This adhesion performance and mechanical characteristic prevent the polyurethane flooring system from breaking as a result of the freezing (because of the water remaining between the stones) in winter and also in hot and cold passages in the final product.

Has better drainage performance.

The stone floor systems, which are expressed as water permeable ground, allow the water to be kept under the surface by using the structural gaps. This system has been used in areas like ways and on the pool sides, where water is unavoidable.

To design this system, it is possible to use different sized stones or different polymer materials as binders. The ability of the epoxy materials to wet the surface is not as good as polyurethane materials. Wetting the surface directly affects the adhesion performance.

The above image shows the contact angles of a liquid with the contact surface. Where The angle between the liquid and the surface is lower than 90°C (C) it explains a good wetted surface and a better adhesion performance. If the contacted angle is greater than 90º (A), it explains that it does not wet the surface and the adhesion will be weaker.

Because epoxy materials are less wetting, at least 10% binder is used to achieve proper adhesion performance. In contrast, polyurethane materials are used at a rate of 4-5% due to their higher wetting ability. Of course, these rates are given for stones of similar size.

The above image shows the contact angles of a liquid with the contact surface. Where The angle between the liquid and the surface is lower than 90°C (C) it explains a good wetted surface and a better adhesion performance. If the contacted angle is greater than 90º (A), it explains that it does not wet the surface and the adhesion will be weaker.

Because epoxy materials are less wetting, at least 10% binder is used to achieve proper adhesion performance. In contrast, polyurethane materials are used at a rate of 4-5% due to their higher wetting ability. Of course, these rates are given for stones of similar size.

İbrahim Kecin

Chemist, M. Sc.

General Manager

PURIN Polyurethane

İbrahim Kecin

Chemist, M. Sc.

General Manager

PURIN Polyurethane

Ayşenur Dede

R&D Manager

PURIN Polyurethane

References

1) Diisocyanates and Polyisocyanates,” CEH Marketing Research Report (SRI), 2009

Ayşenur Dede

R&D Manager

PURIN Polyurethane

References

1) Diisocyanates and Polyisocyanates,” CEH Marketing Research Report (SRI), 2009