Next Generation Inorganic Pigment Dispersant: Additol XL 6577®

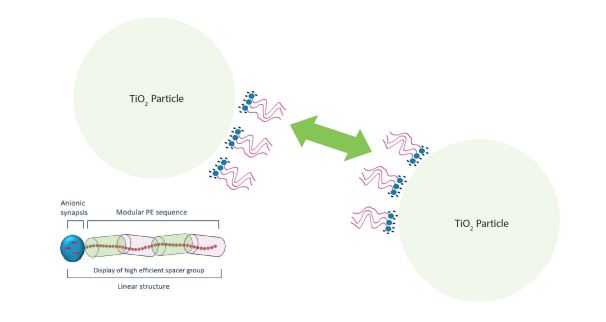

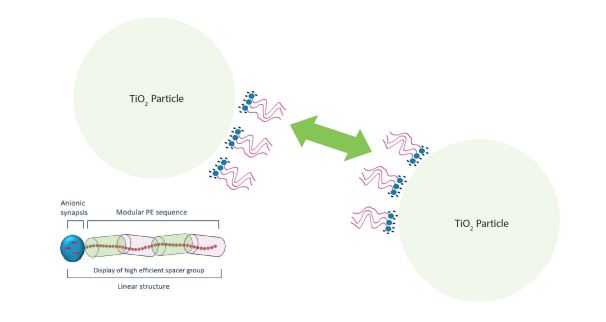

Additol XL 6577 is a new medium molecular weight range dispersant for the use in all solvent borne, high solids, ultra high solids and 100% solids coating & ink systems. A highly efficient anionic ‘mono synapsis’ anchoring function is linked with a special polyester sequence, building a highly efficient spacer unit. The newly designed molecular structure is very reactive, thus Additol XL 6577 bonds rapidly to all inorganic surfaces and allows improved anti-agglomeration and sedimentation.

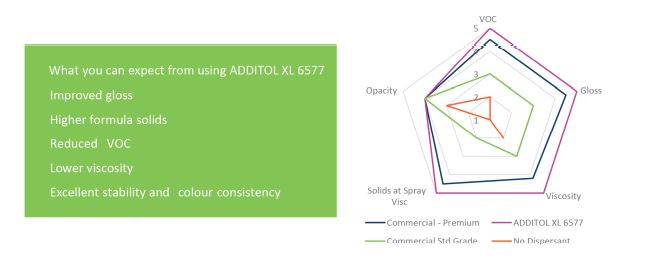

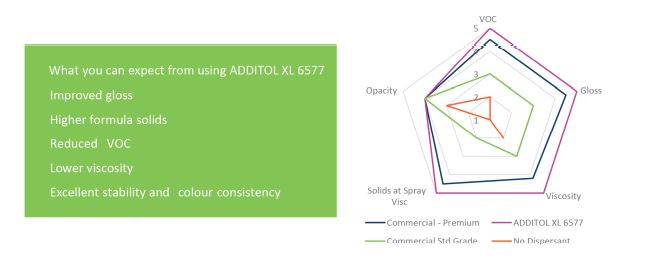

Additol® XL 6577 Benefits

The newest addition to allnex’s globally recognized line of pigment dispersants (and a must for your formulation tool box) is Additol XL 6577. It has been developed to be one of the most efficient dispersants on the markets.

• Conducted multiple benchmarking studies throughout our development process and have

found Additol XL 6577 to be the most efficient when used to disperse inorganic pigments in solvent borne formulations, and also enabling increased pigment loading for both direct grind or production of pigment slurries.

• Additol XL 6577 enables optimized use of expensive pigments in order to maximize efficiency and development of formulas with consistent and premium performance.

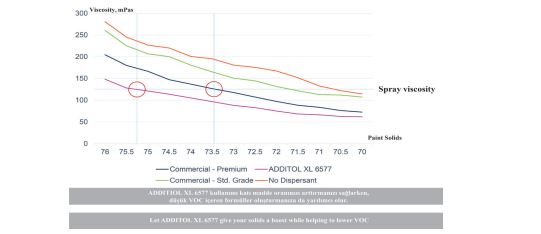

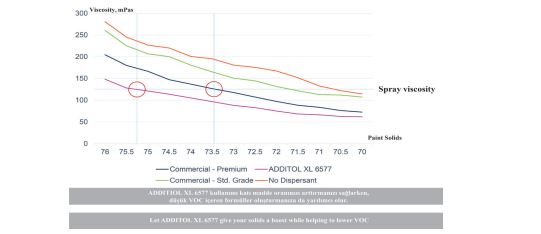

Additol® XL 6577 Benchmarking

Benchmarking Additol XL 6577 vs. commercial dispersants. The chart shows that in a standard white 2K acrylic mono coat the use of Additol XL 6577 enables a 2% solids increase over the premium commercial product and almost 5% over the standard grade at

spray viscosity Part A & Part B mixed and solvent used to thin viscosity to achieve targeted solids-measured after 15 min agitation.

Additol® XL 6577 in Pigment Slurries Key Performance Highlights;

• Greater inorganic pigment loading while keeping slurry viscosity low.

• Allows a reduced dosage level of dispersing additive while maintaining high pigment loading.

• Improved pigment slurry stability against sedimentation during storage.

• Compatible in all solvent based, high solids, ultra high solids and 100% solids liquid resin systems.

• Recommended for factory applied applications including automotive, industrial, M & PC or architectural applications.

• Recommended dosage is 0.25-2.5% on pigment.

Additol® XL 6577 conclusion;

• Stable, low VOC formulas with enhanced opacity

• Increased pigment loading.

• Highly efficient dispersant especially with TiO

2 pigments.

• Prevents agglomeration and setting.

• Very high gloss coatings.

• Consistent colour.

• Improved corrosion performance.

Can Güngör

Business Unit Manager

Kimteks Kimya

Melih Kamhi

Sales Manager

Kimteks Kimya

Can Güngör

Business Unit Manager

Kimteks Kimya

Melih Kamhi

Sales Manager

Kimteks Kimya

Can Güngör

Business Unit Manager

Kimteks Kimya

Melih Kamhi

Sales Manager

Kimteks Kimya

Can Güngör

Business Unit Manager

Kimteks Kimya

Melih Kamhi

Sales Manager

Kimteks Kimya