Introduction

Despite its well established place in the Coatings, Adhesives, Sealant and Elastomer (CASE) sector, polyurethane chemistry is feeling the regulator’s grip tightening: Exposure limits for isocyanates are tightening, solvent-free alternatives are being sought after and many raw materials and additives are being banned. This creates demand for new technical solutions, in particular ones offering ultra-low-monomer hardeners or even isocyanate-free systems. VOC limits and penalties continue to drive high-solids and waterborne systems, with the usual trade-offs in viscosity, leveling, and cure. Raw-material variability and the introduction of bio-based raw materials offers new alternatives at the expense of simplicity, clarity and performance for many formulators.

Technical innovation in coatings for example is often focusing on better understanding and engineering the interface between coating material and the substrate. Hybrid networks that combine urethane/urea segments with other polymer backbones such as siloxane or silane generally improve adhesion retention under UV, moisture, and thermal cycling. The aim is durable bonding to metals, mineral substrates, and low-surface-energy plastics without sacrificing core film properties. In addition, better control of catalysis and co-crosslinking is another key to develop safer and more innovative products and technologies. Amine crosslinkers for example such as polyaspartic amines and silane-modified amines represent promising co-resin components for adjusting pot life, curing profile, surface properties and chemical or water-resistance.

Another area of active research is to find suitable replacements for low-molecular fluorocarbon additives (PFAS) which are experiencing bans and restrictions from regulators worldwide. PFAS-replacement strategies are centered on engineered polysiloxane chemistry with tailored secondary functional groups. Chain structure and functionality are tuned to deliver low friction, ease of cleaning as well as hardness and chemical resistance while maintaining strong substrate adhesion and weathering stability.

No single solution covers all systems, so selection and validation remain critical for any given application, however it is becoming quite apparent that flexibility of solutions and formulation ingredients will play an increasingly important role in future trends and solutions in this industry sector.

Siloxene - A Unique Multifunctional Platform of Innovative Tools for Formulators:

Siloxene AG is a Swiss technology company introducing a unique category of new chemical building blocks, so-called Q–T polysiloxane hybrid resins. Offering a new and completely unique technological approach to modify interfacial chemistry and crosslinking at the molecular level, the platform enables custom-engineered interfaces, connecting silicate-siloxane backbones with conventional resin chemistries. This gives formulators the ability to fine-tune adhesion, wetting, surface free energy, crosslink density and speed with far greater precision. Instead of forcing a choice between processability and performance, Siloxene’s chemistry can couple multiple properties into one and the same raw material, with substantial benefits materializing across the polyurethane value chain—coatings, adhesives, sealants, and elastomers.

Simply put, hybrid Q-T polysiloxane building blocks extend the formulation window—unlocking durability, adhesion and surface functionality with fewer compromises. In the following we are going to present you three independent technical solutions for the PU industry, introducing key products as well as their specific advantages and use cases.

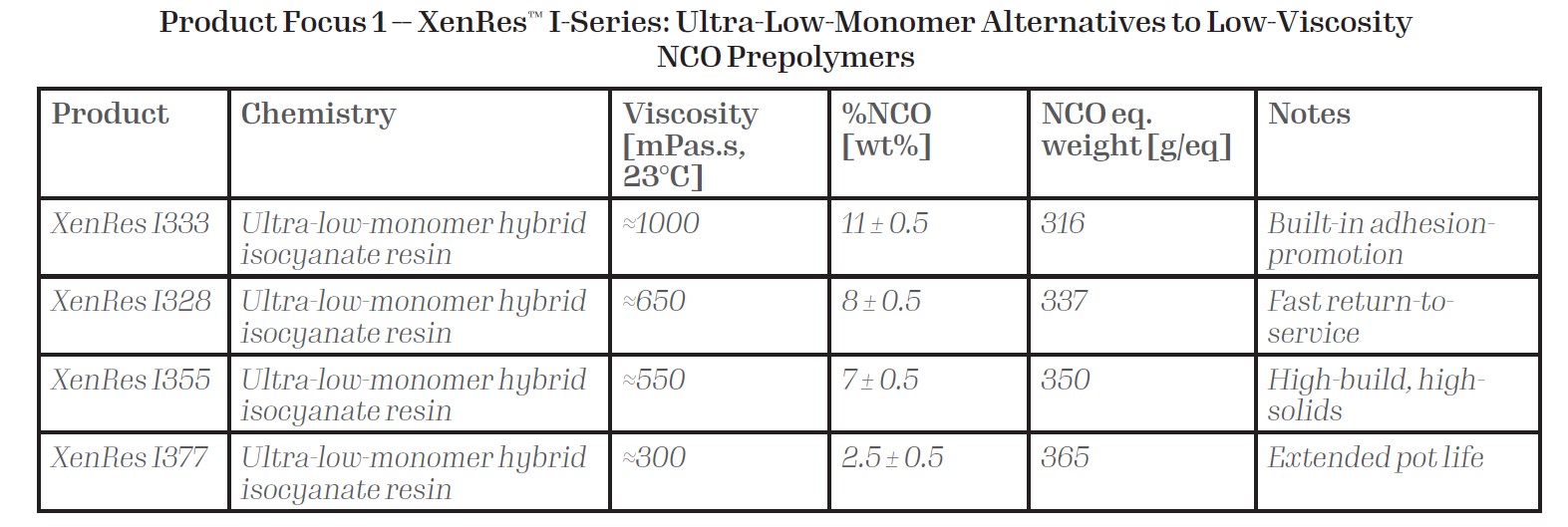

What It Is?

The XenRes I‑series hybrid NCO functional silicate-siloxane resins are polyisocyanate derivatized Q-T polysiloxane materials designed as ultra‑low‑monomer alternatives with built-in secondary features for formulators who need the highest performance low‑viscosity NCO prepolymers. They combine the easy process integration and safer handling with high solids, low viscosity and a built-in adhesion‑promoter package. When used on mineral or metal substrates, this supports rapid strength buildup and excellent water-resistance of the substrate bond.

Why Does It Matter to the Formulator?

As exposure limits on free monomer tighten, the market needs hardeners that reduce risk without compromising handling. The I‑series directly fills that gap: it behaves like a prepolymer in the pot while delivering a hybrid urethane–siloxane network in the film. The result is reliable spray and roll application, robust early hardness development, and long‑term resistance profiles that match or exceed incumbent systems—with a path to lower free monomer and streamlined compliance.

Typical Use Cases:

-2K PU clearcoats, DTM coatings for steel and aluminum,

-Coatings on mineral and ceramic substrates,

-Coatings and flexible sealants for pipelines and tank interiors, concrete structures,

-Hybrid adhesive/sealant systems with extreme water and aging resistance requirements.

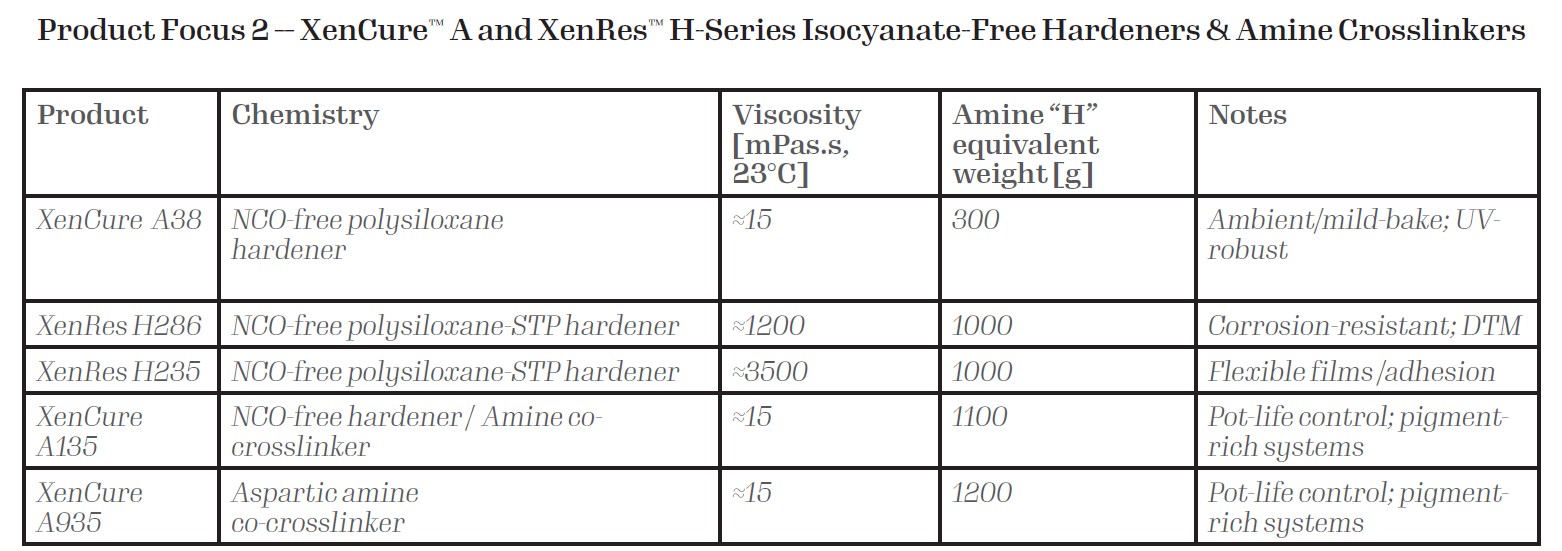

Product Focus 2 — XenCure™ A and XenRes™ H‑Series Isocyanate‑Free Hardeners & Amine Crosslinkers

What It Is?

Siloxene’s isocyanate‑free hardeners (XenCure A‑ and XenRes H‑series) build dense, UV‑robust films via siloxane-silicate condensation networks with hydroxyl‑functional polyols completely without NCOs hardeners. The same compounds (particularly XenCure A polyaspartic resins) can be used as co‑crosslinkers in PUA/PU systems.

On the one hand, they allow coatings producers to formulate 2K coatings completely without isocyanates but also fine‑tune pot-life, rheology and multi-property enhancements of standard isocyanate-based formulations.

Why Does It Matter to the Formulator?

Beyond the clear handling and labelling advantages, NCO‑free systems offer an attractive alternative to NCO-based coating products but without the use of classical non-isocyanate PU chemistries such as costly organic cyclic carbonates. Furthermore, XenCure A / XenRes H hardener chemistry offers not only outstanding adhesion and surface properties but also hydrolysis and weathering resistance.

When used as co‑crosslinkers, these products allow to fine-tune curing whilst improving pigment and filler tolerance compatibilization. Both approaches are engineered to sit inside the familiar 2K workflow. Ingredients and processing (e.g. mixing ratios, equipment handling, fixation and post-cure) are compatible with existing workflows, thus guaranteeing easy integration.

Typical Use Cases:

-DTM (direct-to-metal), primers,

-Coil & can coatings, topcoats, protective coatings, surface finishes,

-OEM parts with complex geometries,

-Architectural and exterior coatings,

-Various types of 2K or “pseudo 1K” adhesives.

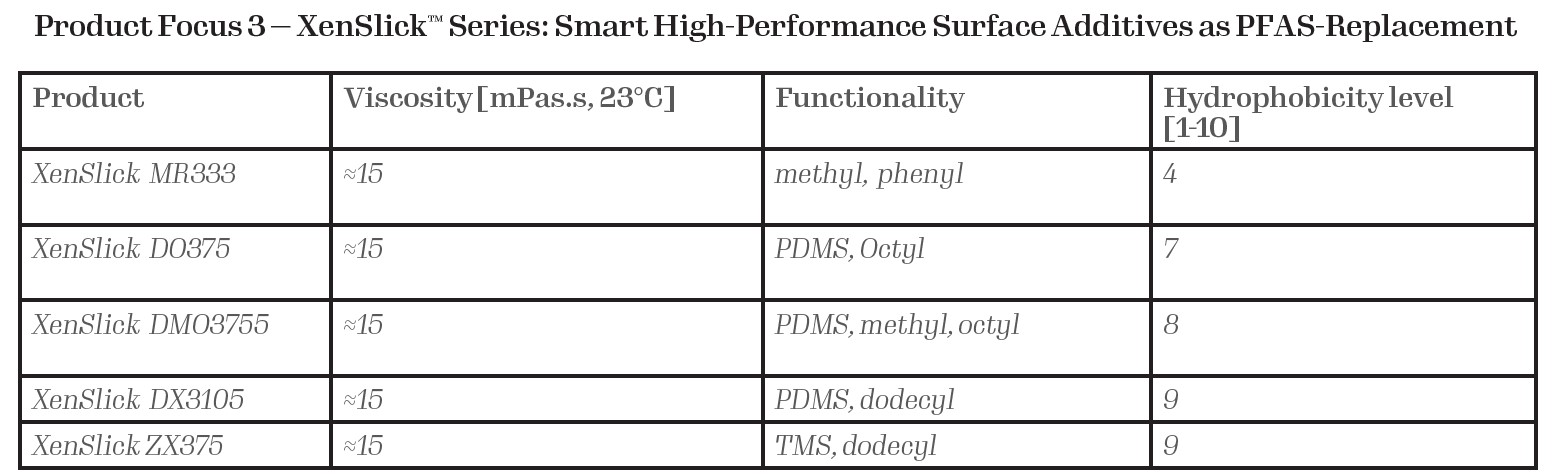

Product Focus 3 — XenSlick™ Series: Smart High-Performance Surface Additives as PFAS‑Replacement

What It Is?

The XenSlick™ ‑series of surface additives comprise alkyl/aryl and silicone‑functionalized Q–T polysiloxane which are designed to replace PFAS‑based surface additives in a wide variety of applications. These products are targeting hydrophobic and oleophobic behaviour, low friction, tunable surface free energy, abrasion and chemical resistance. Theses additives can be customized to integrate smoothly into any binder chemistry (PU, epoxy, STP, UV curable) and are even modifiable to be covalently attached to it.

Why It Matters?

With the industry progressively moving away from persistent “forever chemicals”, formulators need reliable substitutes which can come as close as possible to the previous PFAS. XenSlick™‑series surface additives address this need by providing robust and smart alternatives with a great flexibility in property tailoring. They are available across a wide range of composition and chemistry and can be customized to best match your specific needs.

Typical Use Cases:

-MRO and protective coatings

-Cement protection and architectural coatings

-Flooring topcoats

-Sealants and elastomers

-PU foams

Discover the siloxene Platform

siloxene’s proposition is a high-value add platform technology rather than a single product or solution. By tuning the multifunctional Q–T polysiloxane backbone and fusing them with established resins, hardeners or additives, completely new solution approaches become possible. A team of experienced specialists and engineers is at the forefront of this innovation, allowing wetting, adhesion, curing and other performance-relevant properties to be understood and modified at the molecular level. This unique know-how translates into increased freedom in the formulation: use an ultra‑low‑monomer hybrid isocyanate where processability and Kataplasma performance are key, choose an NCO‑free route where exposure-risks are high or simply boost your product with a PFAS free surface additive. siloxene offers fewer unnecessary trade‑offs, a rapid path to integration and outstanding R&D support.

The industry is focusing on sustainable and non-toxic alternatives and products and solutions. Do not get left behind and consult our experts for sampling, a technical consultation or a custom-development today!

Siloxene AG · Zürichstrasse 38 · CH-8306 Brüttisellen · Switzerland

ARA Kimya · Ataşehir · İstanbul · Türkiye

Exclusive Distributor MENA Region

info@arakem.com · www.arakem.com