Lobe Pumps from Sisdoz for Different Chemical Transfer Needs

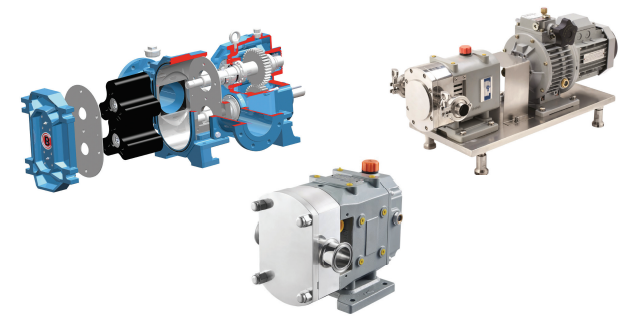

Lobe pumps are in the foreground with their design as well as their practical and easy use in general. This type of pump, which has an important role in ensuring a smooth and impulse-free flow, generally consists of a cast steel or stainless steel body.

One of the most important features of lobe pumps is that they are valveless and positive displacement pumps. It can be used without any problems in the transfer processes of low or high viscosity fluids, especially due to its positive displacement characteristics.

At the same time, in some places these pumps can also be referred to as lobe pumps.

The pumps in question have a relatively sensitive design structure in terms of hygiene, as they find a place in food applications. In fact, FDA approval is needed to ensure that lobe pumps are sufficient in terms of hygiene. Lobe pumps, which have a very wide capacity range, can be produced with lobe alternatives with different designs depending on the customer process.

Advantages of Lobe Pumps

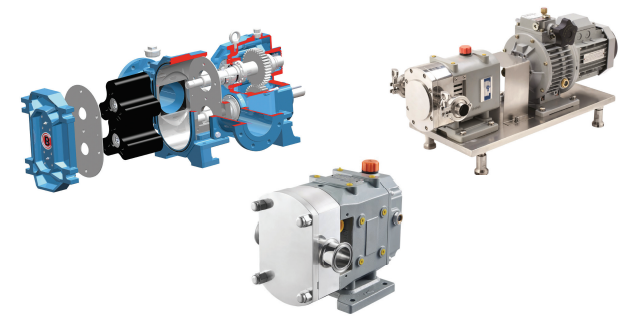

• It provides trouble-free use in the transfer processes of low medium or dense viscosity fluids.

• It allows easy installation or maintenance.

• It can be used for transferring liquids with particles up to certain size.

• It plays a role in the easy transportation of sticky or sensitive fluids.

• Thanks to its stainless steel material, it creates a perfect result in terms of hygiene.

Lobe Pump Features

• Different rotor options,

• Separate lobe options for products containing solid particles,

• Side or top / bottom outlet options,

• Gear box with protective coating,

• Stainless pump body Connection options suitable for food,

• Option to rotate clockwise or counterclockwise.

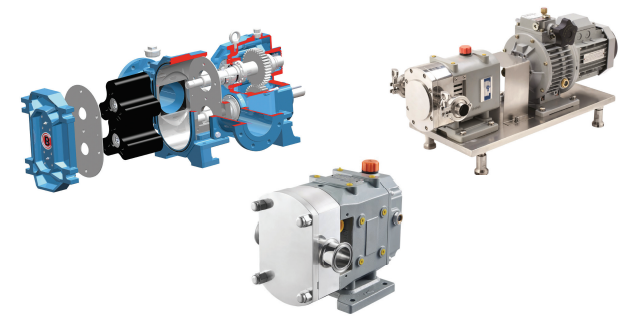

Working Principle of Lobe Pumps

Lobe pumps consist of a pump head in contact with the fluid and a gearbox with timing gears on the back that govern the movement of the lobes. The motion coming from the shaft part of the motor is transferred to the rotor shaft by gears. As the rotor pair begins to rotate, the volume in the inlet section also increases and it also creates a vacuum in the suction section of the pump.

This vacuum also begins to draw fluid into the pump body. As the rotor moves and starts to rotate, the volume in the outlet area decreases and consequently the fluid is transferred to the outlet part. Surface parts of the areas where the fluid passes are completely stainless. Depending on the viscosity condition or chemical properties, different seal or rotor options can be preferred.

There are sensitive gaps between the rotor and the body during the rotation process in lobe pumps. This situation prevents the corrosion of metal parts and the crushing of the products. For this reason, it is actively used in both food and pharmaceutical industries.

Kadir Fakioğlu

Industrial Division Sales Manager

Sisdoz A.Ş.