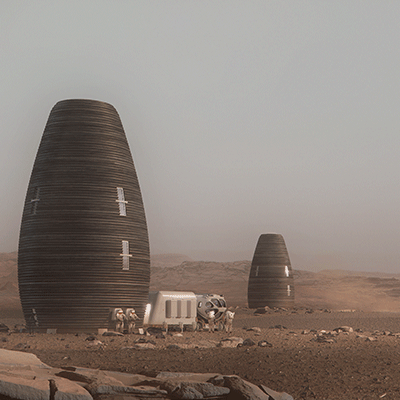

Image Source: NASA

AI SpaceFactory, a New York-based design agency, won a NASA-organized 3D space printing competition about the concept of living on Moon or

Mars. AI SpaceFactory earned $ 500,000 for its efforts, and Penn State, the second-ranked winner, won $ 200,000.

According to NASA, the awards came after a strenuous 30-hour struggle in which participants made up one-third of their architectural designs. Each team used robotic production techniques, which showed that the process could work autonomously, in other worlds, with little human intervention.

This habitat, called MARSHA by AI SpaceFactory, is designed to be long and thin to reduce the need for transport operations required for construction on unfamiliar terrains.

The structure is designed to be constructed on a vertically telescopic arm connected to a wanderer that remains stationary during construction.

AI SpaceFactory plans to adapt the MARSHA design to an eco-friendly Earth habitat called Tera; the design agency announced that the massive funding campaign will begin soon.

“We’ve developed these technologies for space, but these new technologies have the potential to change the way we build on Earth” said David Malott, AI SpaceFactory’s founder and CEO.

In a foreign environment at a distance of 54.6 million kilometers, construction and materials need to be completely rethought.

The discovery and settlement of Mars on any meaningful and sustainable scale will depend on the use of materials found on Mars.

This is achieved through ISRU (in-situ resource utilization) technologies.

ISRU surrounds the rigid limits of the rocket equation, where about 90 kilos of propulsion is required for every 10 kilos of rockets.

Without ISRU, the cost of importing materials from the World makes the project of extraterrestrial futures impossible.

To overcome this, space agencies and companies plan to send machines before human teams to collect raw Mars materials and convert them into houses and other structures.

Thus, using the technologies tested first on Earth, our future Mars habitats can be created before our arrival.

The economic situation for deploying Mars - and the creation of habitats of sufficient size - is based on on-site resource use. In collaboration with Techmer PM, it is formulating an innovative blend of basalt fibers from Martian rock and renewable bioplastic (polylactic acid or PLA) processed from plants grown on Mars.

Top Features

• Basalt fiber is known for its excellent tensile strength. It is comparable to carbon fiber and kevlar but is much easier to produce.

• Due to the low total atomic weight, plastics are effective shields for ionizing cosmic radiation.

• PLA is a strong recyclable thermoplastic and has the advantage of on-site production.

• PLA has the lowest coefficient of thermal expansion among plastics - very important for achieving a composite effect with shredded basalt fiber, which is also very stable.

• Emissions from PLA printing, which is bioplastic, are benign, unlike petrochemical plastics that emit highly toxic microparticles, such as styrene.

• PLA is preferred because of its low conductivity and basalt is among the most effective insulators known. Together, they provide protection against extreme outdoor conditions.

MARSHA is a pioneering principle that rethinks what a living space in Marst can be.

MARSHA is a pioneering principle that rethinks what a living space in Marst can be.

In other words, MARSHA is not another low and wide dome or a closed, semiburied structure, but a bright, multi-storey, corridorless living space that stands upright on the surface of Mars. Where structures in the world are primarily designed for gravity and wind,

Mars conditions require an optimized structure to handle internal atmospheric pressure and thermal stresses.

MARSHA’s unique vertically oriented egg-shaped shape holds a small footprint that minimizes mechanical stresses on the base and top and increases in diameter.

Standing high on the surface gives the human team a superior perspective to observe a dynamic landscape with weather patterns, clouds and changing color tones.

The long and narrow construction reduces the need for a construction machine to move continuously on the surface, reduces risk, and increases speed and accuracy.

These innovations challenge the traditional image of the “space age” domes, focusing on the creation of spaces adapted to both the known and anticipated physical and psychological demands of a Mars mission.

MARSHA uses a unique dual-shell system to isolate habitable areas from structural pressures caused by extreme temperature fluctuations of Mars.

Thanks to this separation, the internal environment is retained in its simple and effective shape by the outer shell.

Thus, the internal environment can be evaluated in the traditional way and freely designed for human needs. MARSHA’s functional areas span four levels, characterized by a unique internal atmosphere that promotes mobility and prevents monotony.

From the large skylight above and through the intermittent windows, the space between the two shells acts as a light well that connects all levels with diffused natural light. This unique space adds dimension to everyday life by allowing the stairs to spread slowly from floor to floor.

Optimized Crew Health

The uncompromising flow of space-specific tasks reveals the stresses and challenges that need to be addressed spatially. However, as ongoing social and mental health is also a critical task, MARSHA offers elements of surprise for the crew to shift out of an extremely prescriptive situation.

The order of MARSHA is considered according to both of these principles. Each level has at least 1 window covering the 360-degree panorama together.

Indirect light from intermittent windows protects the room from the harmful sunlight and cosmic radiation while illuminating the rooms completely. Designed to recreate world light, circadian lighting is used to maximize team health.

Prepared By: B. Serhat Cengiz

References:

• https://www.aispacefactory.com/marsha

• https://www.space.com/nasa-3d-printed-habitat-competition-winners.html

• https://www.businessinsider.com/mars-home-marsha-ai-spacefactory-3d-printed-nasa-2019-6

• https://www.nasa.gov/directorates/spacetech/centennial_challenges/3DPHab/19-017.html

This habitat, called MARSHA by AI SpaceFactory, is designed to be long and thin to reduce the need for transport operations required for construction on unfamiliar terrains.

The structure is designed to be constructed on a vertically telescopic arm connected to a wanderer that remains stationary during construction.

AI SpaceFactory plans to adapt the MARSHA design to an eco-friendly Earth habitat called Tera; the design agency announced that the massive funding campaign will begin soon.

“We’ve developed these technologies for space, but these new technologies have the potential to change the way we build on Earth” said David Malott, AI SpaceFactory’s founder and CEO.

This habitat, called MARSHA by AI SpaceFactory, is designed to be long and thin to reduce the need for transport operations required for construction on unfamiliar terrains.

The structure is designed to be constructed on a vertically telescopic arm connected to a wanderer that remains stationary during construction.

AI SpaceFactory plans to adapt the MARSHA design to an eco-friendly Earth habitat called Tera; the design agency announced that the massive funding campaign will begin soon.

“We’ve developed these technologies for space, but these new technologies have the potential to change the way we build on Earth” said David Malott, AI SpaceFactory’s founder and CEO.

MARSHA is a pioneering principle that rethinks what a living space in Marst can be.

MARSHA is a pioneering principle that rethinks what a living space in Marst can be.