The first-generation Silane Terminated Polyethers (STPEs) were developed in 1978 in Japan as a construction sealant and was named MS

PolymerTM which stands for modified silicone.

Positive properties of both silicones and polyurethanes (PU) are combined. It differentiates itself from these technologies as it consists of a functionalized polyether backbone with silane terminal groups, without the need for harmful isocyanates and/or solvents.

Chemical Structures Although the name was derived from modified silicone, the backbone differs from the backbone of silicones.

After curing, the STPE or MS PolymerTM will only consist of 2 siloxane bonds separated by a polyether providing higher flexibility whereas the silicone backbone consists of multiple siloxane bonds. The backbone of PU can be very similar to STPE but contains urethane bonds. More detailed structures are given in Figure 1.

Figure 1. Structure of the different sealant polymer technologies

Performance Comparison STPEs combine the positive properties of silicones and polyurethanes as shown in Table 1. The adhesives and sealants based on this technology show a permanent elastic behavior, even at sub-zero temperatures, with a strength comparable to polyurethanes.

Table 1. Comparison of properties MS Polymer, PU and silicone

Source: Table from MS Polymers in “Hybrid” Sealants by Edward M. Petrie.

High Strength MS PolymerTM Over the years the polymer backbone of MS PolymerTM, which was initially developed for sealants only, has been modified to broaden the application field to adhesives. A further change in the design recently led to the development of high strength polymers.

Two technologies are available, either based on the unique Kaneka silane acryl modified polymers or based on a modified polyether backbone.

In the high strength silane acryl modified polymers, polymers with different structures, and hence Tg, are blended in order to control the compatibility.

During curing the compatibility will change and a phase separation between the cured polyacrylate and the polyether parts occurs, resulting in homogeneously distributed acrylic and ether domains, the so-called sea-island structure.

The acrylic domains will provide high strength and good adhesion to plastics, whereas the ether domains will give elasticity to the cured system.

The other option is a modified polyether backbone which will lead to an increased number of branching points on the backbone which results in more entanglements and a denser polymer matrix after curing. The increased number of siloxane bonds will provide the higher strength.

When blended with silane acryl modified polymers strength can even be increased to a level of more than 10MPa (tensile strength at break). In figure 2 an overview is shown to demon strate the final strength and elasticity of a formulated end product based on the different range of polymers.

The excellent compatibility of the MS PolymerTM makes it possible to blend it with epoxies to act as a flexibilizer.

Figure 2. Schematic comparison of the different polymer technologies

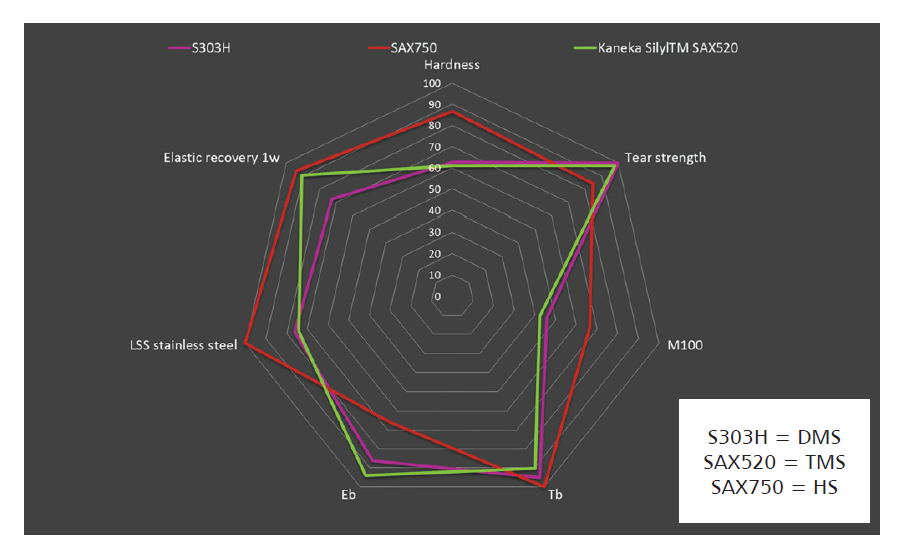

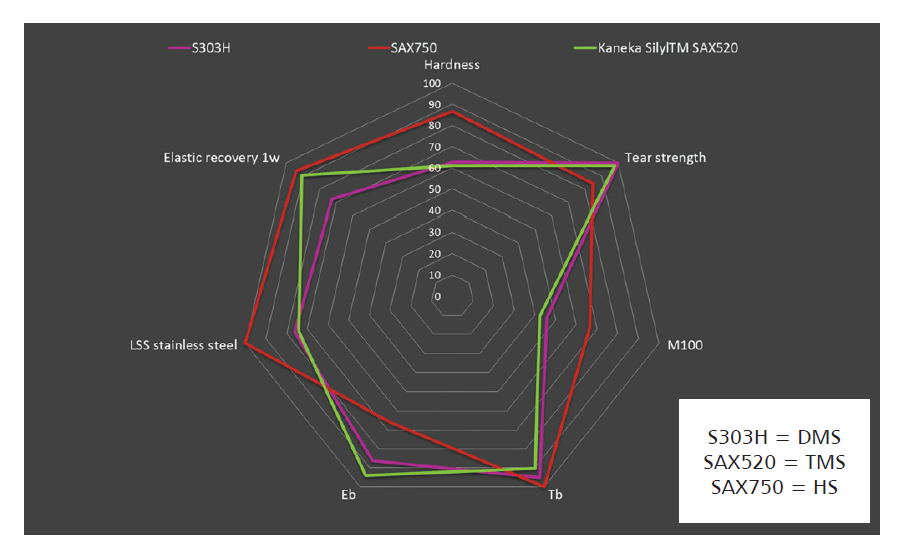

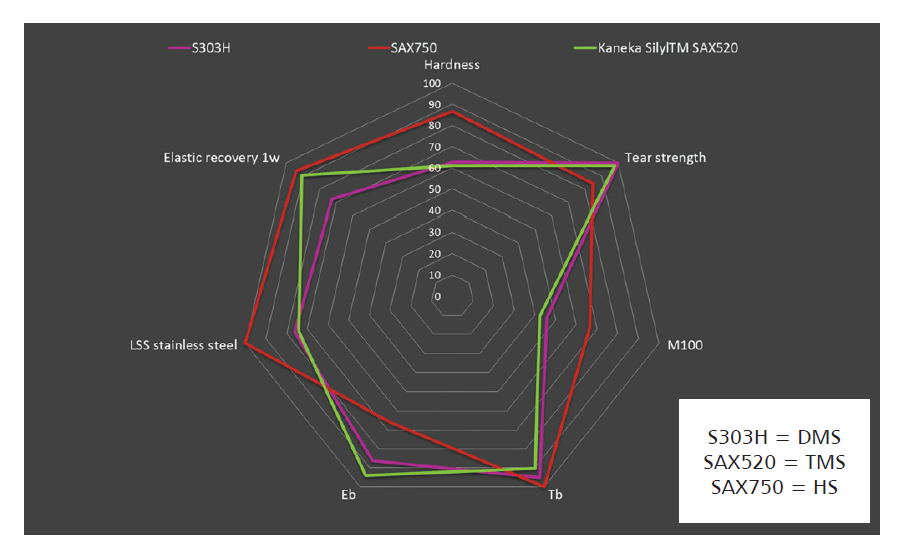

Compared to the standard MS PolymerTM the high strength MS Polymers will provide an overall upgrade of the properties, especially the mechanical properties. In figure 3 a 1-to-1 relative comparison of the mechanical properties in a formulated product is shown, proving that the high strength polymers lead to higher quality products.

The high strength polymers can be applied in several high demanding adhesive applications as D4 wood adhesive, semistructural adhesive, adhesive for dissimilar materials, plastic adhesive, DIY repair adhesive, low water uptake coatings.

Figure 3. Relative comparison in % of the different mid modulus MS Polymer technologies

Acryl Modified MS PolymerTM for Better UV Resistancy The acryl modified MS PolymerTM does not only improve the adhesion strength, but also other properties such as UV resistance and weatherability.

The weatherability of an acryl modified MS PolymerTM was measured in a formulated product by performing a cyclic test with a combination of carbon arc lamp and water spray (SWOM test).

As can be observed in Table 2 cracks start to form with a standard DMSMS PolymerTM after 1500 hours of exposure. Crack formation with the acryl modified MS PolymerTM is only observed after 4500 hours (27 weeks) exposure, 3 times longer compared to the standard MS PolymerTM exposure.

It is obvious that by using the new acryl modified polymers weatherability significantly increases and will result in improved heat/water resistance.

Table 2. Comparison of weatherability test standard MS PolymerTM with acrylic modified MS PolymerTM

General Conclusion A new generation of high strength Kaneka MS PolymerTM grades was developed, and it is shown that these polymers improve the overall mechanical properties of sealants and adhesives compared to the standard STPE. Higher strength and modulus can be achieved up to the level of polyurethanes.

On top, also other properties such as heat/moisture resistance, elastic recovery, adhesion to plastics, etc. have been improved. These polymers offer new opportunities such as repair adhesives, (semi-) structural adhesives, etc...

Jo Indesteege - Business Manager - MS Polymer Division EMEA Region