We had a very enjoyable interview with Mr. Tolga Demirözü, General Manager of

BASF Türk. Mr. Demirözü shared with us information on important issues such as

the product groups offered by the company to the paint industry, activities in the

Innovation Center and sustainability studies.

Could you please tell us about yourself, your academic and professional background so that our readers can get to know you better?

After graduating from Kadıköy Anatolian High School, I completed my undergraduate and graduate education at Yıldız Technical University, Department of Chemical Engineering. I started my career journey in the pharmaceutical industry and continued with management positions in the fields of supply chain, planning, business excellence in international markets and factory logistics at Nestle Türkiye. Then, I managed projects on supply chain operations for the consumer and manufacturing industries within Deloitte Türkiye. Between 2008 and 2018, I took part in different positions within BASF Türk and assumed the position of Operations Director. In 2018, I continued my career as PETKİM Deputy General Manager and then as SOCAR Corporate Ventures and New Business Group Director. As of May 2022, I returned to BASF Türk as the Managing Director. I am currently the Managing Director of BASF Türk and the President of the Türkiye-Azerbaijan- Georgia Country Group. In addition, I am a member of the board of directors of YASED, IMSAD, BOSAD and TKSD associations.

Could you please share with us the founding story of BASF Türk and its current structure?

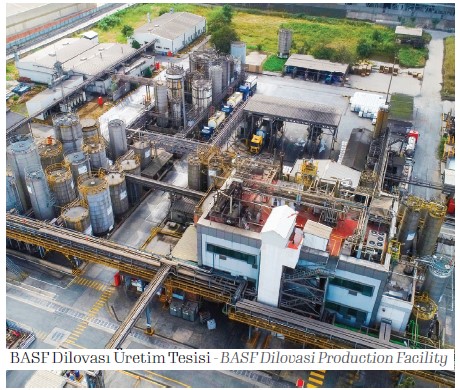

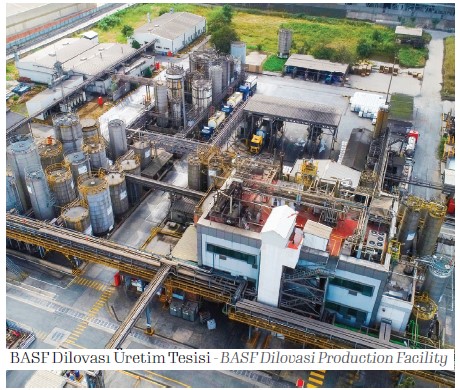

We made our first sales in Türkiye in 1880 and after the partnership we established with Sümerbank in 1969, we put our first factory into service in 1970. We have been supplying chemical products to many industrial sectors for half a century and we continue to contribute to the development of many sectors and the Turkish economy since the establishment of the Republic. As BASF Türk, we employ nearly 500 people in our head office in Istanbul, in our-regional offices, in our two production facilities and in our Innovation Center. Together with our other legal entities under the umbrella of BASF, Chemetall and Nunhems, our employment figures rise to more than 700.

What are the sectors you serve and which product groups do you offer to the paint industry?

Among the areas in which BASF operates in Türkiye are; chemicals, plastics, dispersions and pigments, care chemicals, specialty chemicals and plant protection. BASF products and solutions are used in a wide range of industries, including electrical and electronics, automotive, construction, detergents and cleaning, pharmaceuticals and cosmetics, animal feed, agriculture and food.

We carry out important activities in the automotive original production paints, automotive renewal paints and construction and industrial paint sectors in Türkiye. In our Innovation Center, we organize trainings on product use and color matching as well as product trials in our laboratory designed for automotive repair professionals. We also provide color matching and formulation related services with the color laboratory. Again, in our Innovation Center, we provide formulation and test support and give technical seminars by using dispersions, resins and additives in the laboratory where construction and industrial paint formulations are developed.

Could you please tell us about the features of the BASF Innovation Center and your activities there?

In 2020, we launched our BASF Türkiye Innovation Center. In our center, which started its operations in the Technopark Istanbul campus, we develop special solutions for our local customers, taking into account the characteristics of the relevant geography. We carry out new solutions for customer needs in the fields of Food Solutions, Seed Solutions, Domestic Care and Industrial Cleaning, Personal Care, Engineering Plastics and Polyurethane, Automotive Renewal Paints and Construction and Industrial Paints.

Our Innovation Center: It is a platform where we produce common ideas with our customers, employees, universities and entrepreneurs and develop sustainable innovation projects in line with our global vision. Our vision is to develop an innovation ecosystem that enables the production of common ideas and values and includes all our stakeholders.

We now live in a digitalized world, and in this direction, the chemical industry has started to benefit from digital technologies. What are your thoughts on this issue and in which areas do you benefit from digital technologies?

At BASF, we use digital technologies and data to create value for our customers and increase the efficiency and effectiveness of our processes. From R&D to supply chain and production, we create an effective system by deploying digital solutions.

By following our pioneering practices in the world, we implement digital solutions in many areas in our country. In particular, our Innovation Center provides us with opportunities

to implement these solutions. For example, by using virtual reality glasses in our Automotive Refinish Competence Center, we both shorten the processes and prevent possible carbon emissions in paint training.

By using the same technology in the farmer trainings of our Agricultural Solutions unit, we reach more farmers than previous practices and increase expertise in correct agricultural practices. We also benefit from digital technologies in occupational safety practices, which are the top priority for us, and prevent occupational accidents.

In this regard, we have also been deemed worthy of awards in our country and throughout BASF Europe. Finally, our chatBASF application, which is based on artificial intelligence, was put into the service of all our employees. In the coming years, we expect digital transformation to accelerate exponentially in all areas.

You have a goal of zero carbon emissions by 2050. Could you please share this goal and the steps you have taken towards this goal?

As BASF, our company goal is to zero our CO2 emissions by 2050 in line with the “Net Zero” approach we have put forward globally. As a sub-target, we plan to reduce our CO2

emissions by 25% by 2030. There are many investments that have been commissioned in this way and projects that we have contributed to as a country organization.

For example, we are making a great effort to transition to renewable energy in our production facilities. At our Çayırova production facility, we reduced our carbon emissions by 65% compared to 2018. We now provide our energy from 100% green energy. We have already achieved the carbon emission reduction amount we planned for 2030 through various operational excellence studies. While recording these developments, which are of great importance especially for the chemical industry, our efforts continue to “reduce

the carbon emissions of our customers”, which is one of our main goals.

Could you please tell us about the importance of the Turkish market for BASF and how do you evaluate the development of the coatings industry in Türkiye?

For BASF, Türkiye is a trusted market with various potential. The investments made for many years, the Innovation Center opened in 2020 and the new production facility investments made this year prove this approach. Our ability to meet the needs quickly especially with our qualified workforce, and our flexibility in terms of both production

and logistics make us very advantageous in our region.

In 2022, the paint industry, like all other sectors, experienced the effects of the Russia-Ukraine war and the subsequent supply chain problems and energy crisis. However, strong paint manufacturers in our country have made an effort to turn the situation in a positive direction by increasing their production. As BASF, we aimed to increase our supply share in North African and Central Asian countries in our foreign markets this year for raw materials for decorative paints and construction chemicals. However, we think that demand in European markets will continue to rise towards the end of the year.

As BASF, with our products and solutions, we support the success of our customers in Türkiye in export markets, which is a very strong aspect. In the medium and long term,

we believe that our strength in exports will also have positive reflections on the domestic market.

As BASF, with our products and solutions, we support the success of our customers in Türkiye in export markets, which is a very strong aspect. In the medium and long term,

we believe that our strength in exports will also have positive reflections on the domestic market.

As BASF, with our products and solutions, we support the success of our customers in Türkiye in export markets, which is a very strong aspect. In the medium and long term,

we believe that our strength in exports will also have positive reflections on the domestic market.