Innovative Water-Based Polymer Technologies for Industrial Coatings and Printing Industries

In many applications, such as wood coatings or in the printing industry, formulations based on modern acrylate polymer technologies provide excellent coating results, while at the same time utilising the advantages of water-based coating materials. They are the environmentally conscious choice compared to solvent-based coatings and during processing, whether industrial or do-it-yourself (DIY), water-based coatings are safe in use and very easy to handle.

Solvent-based paints contain higher levels of organic compounds than water-based paints. However, these paints and their underlying polymers are being more and more phased out because of the volatile organic compounds (VOCs) being released into the atmosphere

upon evaporation, resulting in a strong odour and toxic effects on the environment. Stricter environmental regulations have required paint manufacturers to drastically reduce the VOC content of their paints. In addition to these greater environmental demands the quality

requirements of paint manufacturers are also becoming Increasingly demanding, for example in terms of appearance, feel or durability of high-performance coatings.

For formulations that meet these challenges, Zschimmer & Schwarz offers tailor-made innovative water-based polymer technologies with the highest standards of quality and cost-effectiveness. Some of these technologies from the product portfolio are briefly presented here.

Polymer Technologies by Application

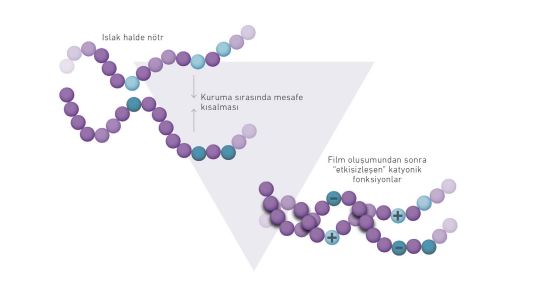

1. Interpenetrating Polymer Network (IPN)

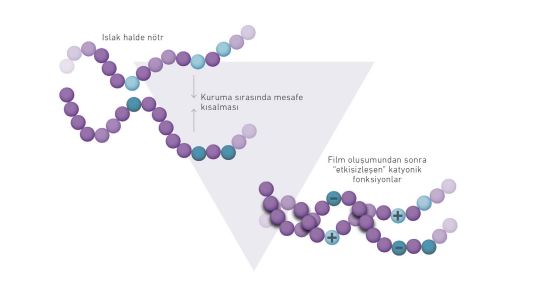

The IPN involves two different ionic structures in the same polymer network at a neutral pH value. Overall, the polymer exhibits an anionic behaviour and can thus be formulated like an anionic polymer. Cationic functionalities then form during drying, providing excellent

tannin, stain and dye blocking without the compatibility problems common to cationic polymers. Adhesion to various substrates such as aluminium, PVC or wood is also improved. At the same time, VOC requirements for the formulation remain low.

Features & Benefits

• Enables cationic functionalities in anionic formulations,

• Excellent tannin, stain and dye blocking,

• Excellent adhesion to multiple substrates,

• High compatibility with other resins and additives,

• Low VOC requirements to formulate coatings.

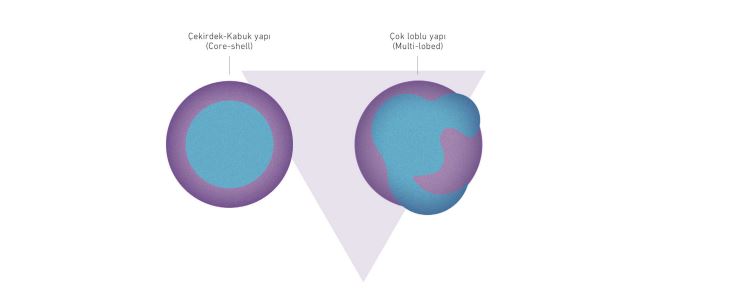

2. Multiphase Technology

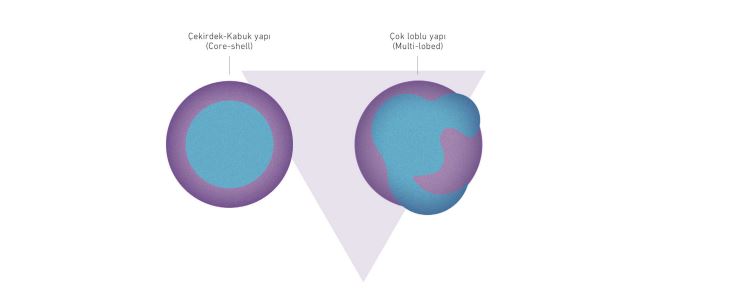

2. Multiphase Technology

Using a two-step synthesis process, multiphase technology combines two different types of polymers in the same polymer network. This allows a balanced combination and thereby an overall improvement of the physical properties of the two polymers. A very good hardness and chemical resistance balanced with a moderate film-forming temperature benefits

applications in the wood sector in particular. This process also means that no or only a small amount of emulsifiers is required. Thus, some of these products are approved for indirect food contact in compliance with the FDA and Swiss Ordinance.

Features & Benefits

• Very low to zero emulsifier content,

• Good balance between hardness, chemical resistance and film forming,

• Excellent adhesion to multiple substrates,

• FDA-approved for indirect food contact,

• Swiss Ordinance-approved.

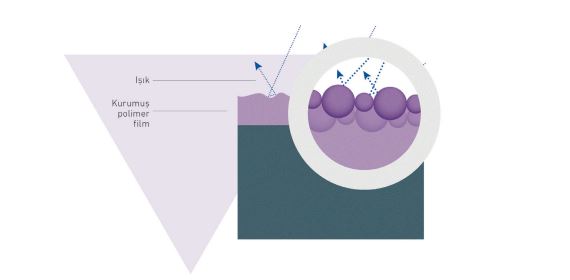

3. Self Matte Polymer Technology

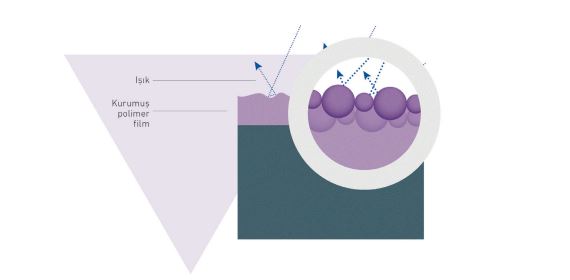

3. Self Matte Polymer Technology

Using a proprietary process, Zschimmer & Schwarz offers an inherently matte acrylate polymer. After drying, a film with low gloss, high flexibility and excellent stability is formed. This technology also provides excellent adhesion to various substrate types.

The polymer is a matte binder and not a “liquid matting agent”, meaning it can be formulated as a conventional (water-based) acrylic polymer, replacing the binder. It can be used as a single binder or in a blend with polyurethanes and has low foaming and low VOC requirements. The time and labourconsuming incorporation of solid matting agents is completely eliminated, making the formulation much simpler, more stable and more economical. Unlike conventional matting agents, the matte polymer also has excellent transparency.

Features & Benefits

• Easy to formulate with low foaming,

• Low VOC demand,

• Stable-no settling of the polymer.

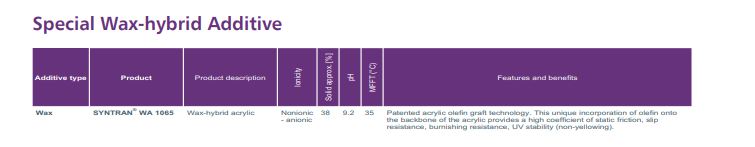

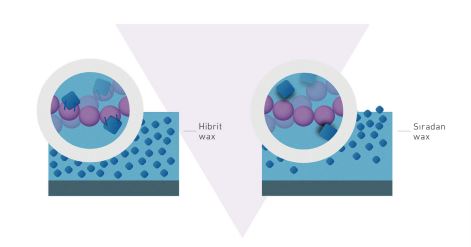

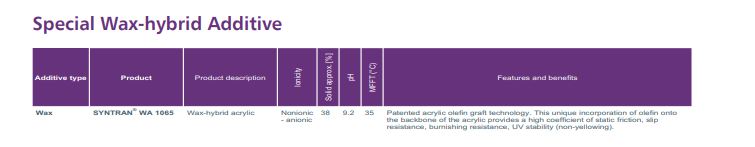

4. Wax-Hybrid Technology

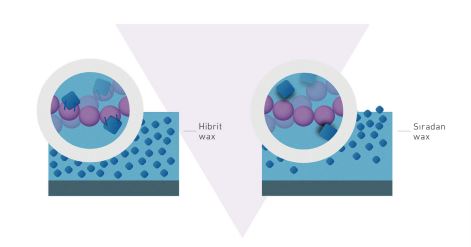

4. Wax-Hybrid Technology

Our wax-hybrid technology is a patented process for combining wax and acrylate in a single polymer network. This prevents the wax from migrating to the surface as it dries, resulting in a more uniform film composition that improves the appearance and performance of the coating. The hybrid polymer exhibits anionic behaviour and broad compatibility with other water-based polymers. The positive properties of waxes, such as increased slip or abrasion resistance and improved water resistance, can thus be optimally utilised.

Features & Benefits

• Wax grafted to the polymer network,

• Even distribution in liquid and dried form,

• Enhanced wear resistance,

• Improved water resistance,

• Soft and flexible, good response to buffing for scratch repair and gloss,

• Slip resistance.

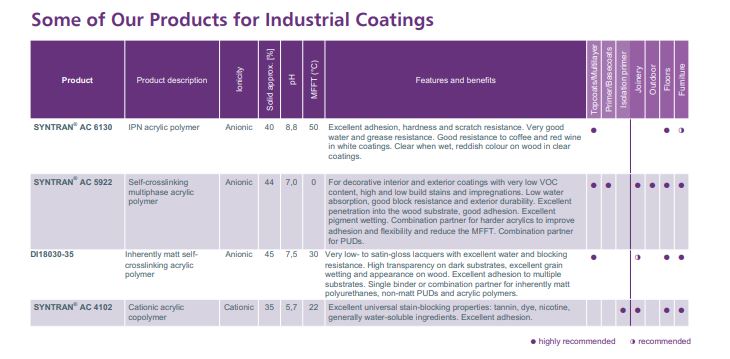

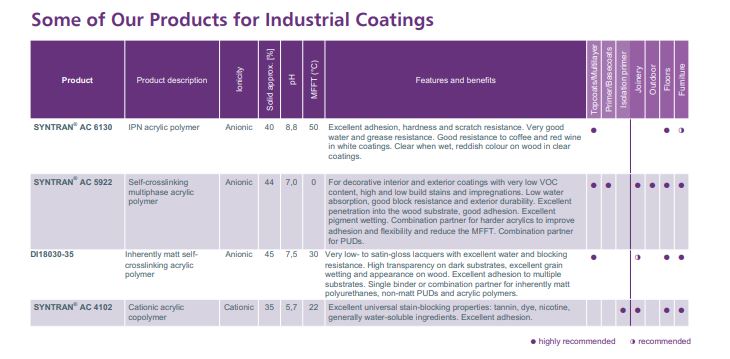

[caption id="attachment_136884" align="aligncenter" width="471"]

Products for wood paints are given in the table below.[/caption]

Zschimmer & Schwarz is a global supplier of chemical auxiliaries and specialities headquartered in Lahnstein near Koblenz, Germany. The family business was founded in Chemnitz in 1894 and is positioned across industries with different business divisions. Our core business is the development, production and supply of tailor-made chemical auxiliaries for the leather, fur, ceramic, textile and chemical fibre industries. Manufacturers of cleaning agents, personal care products, paints and coatings, lubricants and industrial applications all over the world trust in the company’s chemical specialities as well.

The portfolio of the paints & coatings division serves a wide range of end-use applications from the industrial coatings and graphic arts sectors. We offer technologies and materials for the treatment and coating of surfaces such as wood, paper, metal, textile and concrete for best results. Innovative polymer technologies, tailored to the application and requirements of our customers, provide the necessary “plus” in the formulation. As specialists in environmentally conscious, water-based polymers, we offer optimised customer solutions with the highest standards of quality and cost-effectiveness,

which we are producing at our sites in Europe, North America and Asia. Our portfolio comprises state-of-theArt polymer technologies like self-crosslinking polymers which can be fully cured at room temperature without limitations in storage stability. It also includes cationic as well as highly charged soluble resins for improvements in wetting, dispersing or adhesion.

In addition to these established technologies, we focus our developments of polymers for water-based applications on modern, innovative concepts, which we are briefly presenting here.

Dr. Fabian Gyger

Global Product Manager

Zschimmer & Schwarz Paints & Coatings Division

Erkan Yılmaz

Area Sales Manager Turkey, Middle East and North Africa

Zschimmer & Schwarz Paints & Coatings Division

Dr. Yasemin İlhan

Sales & Marketing Manager

Reaksiyon Kimya A.Ş.

2. Multiphase Technology

Using a two-step synthesis process, multiphase technology combines two different types of polymers in the same polymer network. This allows a balanced combination and thereby an overall improvement of the physical properties of the two polymers. A very good hardness and chemical resistance balanced with a moderate film-forming temperature benefits

applications in the wood sector in particular. This process also means that no or only a small amount of emulsifiers is required. Thus, some of these products are approved for indirect food contact in compliance with the FDA and Swiss Ordinance.

Features & Benefits

• Very low to zero emulsifier content,

• Good balance between hardness, chemical resistance and film forming,

• Excellent adhesion to multiple substrates,

• FDA-approved for indirect food contact,

• Swiss Ordinance-approved.

2. Multiphase Technology

Using a two-step synthesis process, multiphase technology combines two different types of polymers in the same polymer network. This allows a balanced combination and thereby an overall improvement of the physical properties of the two polymers. A very good hardness and chemical resistance balanced with a moderate film-forming temperature benefits

applications in the wood sector in particular. This process also means that no or only a small amount of emulsifiers is required. Thus, some of these products are approved for indirect food contact in compliance with the FDA and Swiss Ordinance.

Features & Benefits

• Very low to zero emulsifier content,

• Good balance between hardness, chemical resistance and film forming,

• Excellent adhesion to multiple substrates,

• FDA-approved for indirect food contact,

• Swiss Ordinance-approved.

3. Self Matte Polymer Technology

Using a proprietary process, Zschimmer & Schwarz offers an inherently matte acrylate polymer. After drying, a film with low gloss, high flexibility and excellent stability is formed. This technology also provides excellent adhesion to various substrate types.

The polymer is a matte binder and not a “liquid matting agent”, meaning it can be formulated as a conventional (water-based) acrylic polymer, replacing the binder. It can be used as a single binder or in a blend with polyurethanes and has low foaming and low VOC requirements. The time and labourconsuming incorporation of solid matting agents is completely eliminated, making the formulation much simpler, more stable and more economical. Unlike conventional matting agents, the matte polymer also has excellent transparency.

Features & Benefits

• Easy to formulate with low foaming,

• Low VOC demand,

• Stable-no settling of the polymer.

3. Self Matte Polymer Technology

Using a proprietary process, Zschimmer & Schwarz offers an inherently matte acrylate polymer. After drying, a film with low gloss, high flexibility and excellent stability is formed. This technology also provides excellent adhesion to various substrate types.

The polymer is a matte binder and not a “liquid matting agent”, meaning it can be formulated as a conventional (water-based) acrylic polymer, replacing the binder. It can be used as a single binder or in a blend with polyurethanes and has low foaming and low VOC requirements. The time and labourconsuming incorporation of solid matting agents is completely eliminated, making the formulation much simpler, more stable and more economical. Unlike conventional matting agents, the matte polymer also has excellent transparency.

Features & Benefits

• Easy to formulate with low foaming,

• Low VOC demand,

• Stable-no settling of the polymer.

4. Wax-Hybrid Technology

Our wax-hybrid technology is a patented process for combining wax and acrylate in a single polymer network. This prevents the wax from migrating to the surface as it dries, resulting in a more uniform film composition that improves the appearance and performance of the coating. The hybrid polymer exhibits anionic behaviour and broad compatibility with other water-based polymers. The positive properties of waxes, such as increased slip or abrasion resistance and improved water resistance, can thus be optimally utilised.

Features & Benefits

• Wax grafted to the polymer network,

• Even distribution in liquid and dried form,

• Enhanced wear resistance,

• Improved water resistance,

• Soft and flexible, good response to buffing for scratch repair and gloss,

• Slip resistance.

[caption id="attachment_136884" align="aligncenter" width="471"]

4. Wax-Hybrid Technology

Our wax-hybrid technology is a patented process for combining wax and acrylate in a single polymer network. This prevents the wax from migrating to the surface as it dries, resulting in a more uniform film composition that improves the appearance and performance of the coating. The hybrid polymer exhibits anionic behaviour and broad compatibility with other water-based polymers. The positive properties of waxes, such as increased slip or abrasion resistance and improved water resistance, can thus be optimally utilised.

Features & Benefits

• Wax grafted to the polymer network,

• Even distribution in liquid and dried form,

• Enhanced wear resistance,

• Improved water resistance,

• Soft and flexible, good response to buffing for scratch repair and gloss,

• Slip resistance.

[caption id="attachment_136884" align="aligncenter" width="471"] Products for wood paints are given in the table below.[/caption]

Products for wood paints are given in the table below.[/caption]

Zschimmer & Schwarz is a global supplier of chemical auxiliaries and specialities headquartered in Lahnstein near Koblenz, Germany. The family business was founded in Chemnitz in 1894 and is positioned across industries with different business divisions. Our core business is the development, production and supply of tailor-made chemical auxiliaries for the leather, fur, ceramic, textile and chemical fibre industries. Manufacturers of cleaning agents, personal care products, paints and coatings, lubricants and industrial applications all over the world trust in the company’s chemical specialities as well.

The portfolio of the paints & coatings division serves a wide range of end-use applications from the industrial coatings and graphic arts sectors. We offer technologies and materials for the treatment and coating of surfaces such as wood, paper, metal, textile and concrete for best results. Innovative polymer technologies, tailored to the application and requirements of our customers, provide the necessary “plus” in the formulation. As specialists in environmentally conscious, water-based polymers, we offer optimised customer solutions with the highest standards of quality and cost-effectiveness,

which we are producing at our sites in Europe, North America and Asia. Our portfolio comprises state-of-theArt polymer technologies like self-crosslinking polymers which can be fully cured at room temperature without limitations in storage stability. It also includes cationic as well as highly charged soluble resins for improvements in wetting, dispersing or adhesion.

In addition to these established technologies, we focus our developments of polymers for water-based applications on modern, innovative concepts, which we are briefly presenting here.

Dr. Fabian Gyger

Global Product Manager

Zschimmer & Schwarz Paints & Coatings Division

Erkan Yılmaz

Area Sales Manager Turkey, Middle East and North Africa

Zschimmer & Schwarz Paints & Coatings Division

Dr. Yasemin İlhan

Sales & Marketing Manager

Reaksiyon Kimya A.Ş.

Zschimmer & Schwarz is a global supplier of chemical auxiliaries and specialities headquartered in Lahnstein near Koblenz, Germany. The family business was founded in Chemnitz in 1894 and is positioned across industries with different business divisions. Our core business is the development, production and supply of tailor-made chemical auxiliaries for the leather, fur, ceramic, textile and chemical fibre industries. Manufacturers of cleaning agents, personal care products, paints and coatings, lubricants and industrial applications all over the world trust in the company’s chemical specialities as well.

The portfolio of the paints & coatings division serves a wide range of end-use applications from the industrial coatings and graphic arts sectors. We offer technologies and materials for the treatment and coating of surfaces such as wood, paper, metal, textile and concrete for best results. Innovative polymer technologies, tailored to the application and requirements of our customers, provide the necessary “plus” in the formulation. As specialists in environmentally conscious, water-based polymers, we offer optimised customer solutions with the highest standards of quality and cost-effectiveness,

which we are producing at our sites in Europe, North America and Asia. Our portfolio comprises state-of-theArt polymer technologies like self-crosslinking polymers which can be fully cured at room temperature without limitations in storage stability. It also includes cationic as well as highly charged soluble resins for improvements in wetting, dispersing or adhesion.

In addition to these established technologies, we focus our developments of polymers for water-based applications on modern, innovative concepts, which we are briefly presenting here.

Dr. Fabian Gyger

Global Product Manager

Zschimmer & Schwarz Paints & Coatings Division

Erkan Yılmaz

Area Sales Manager Turkey, Middle East and North Africa

Zschimmer & Schwarz Paints & Coatings Division

Dr. Yasemin İlhan

Sales & Marketing Manager

Reaksiyon Kimya A.Ş.