According to the Syloid product range technical studies of Grace - world’s one of the biggest silica producer – we have to consider 3 main things for matting efficiency: Porosity, particle size and surface treatment.

Additionally, dry film thickness and some other dynamics that affects film surface like resin type, solid content (or non-volatile compounds), solvent type and drying time are also important factors.

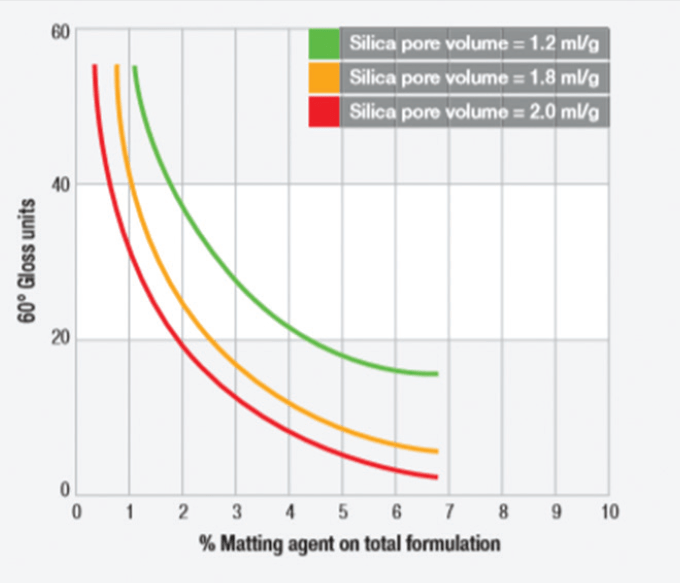

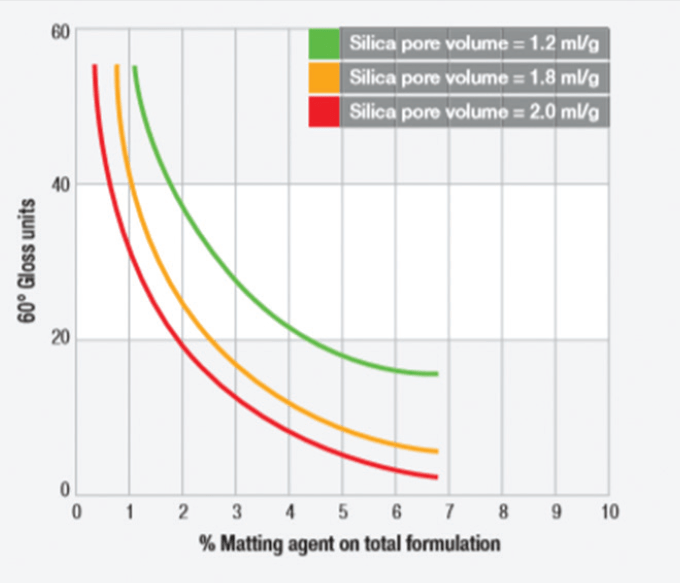

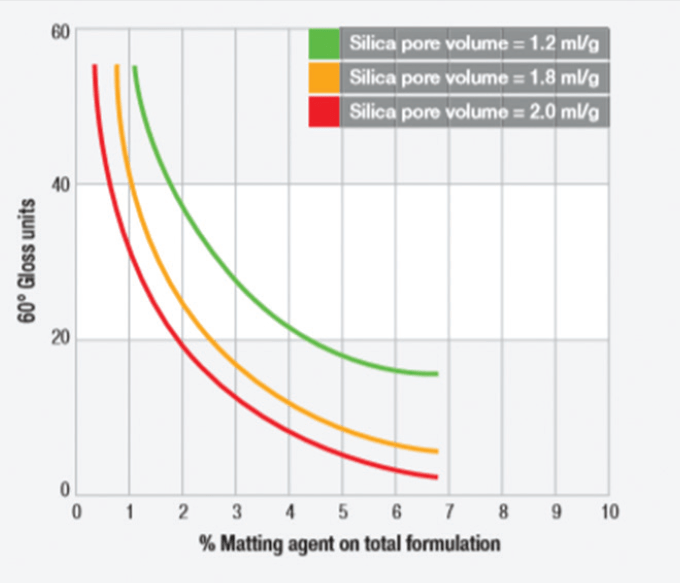

In Graphic 1, there are 3 different matting agents with same particle size but different pore volumes. The higher the pore volume of the silica, the more efficient is the SYLOID® silica grade.

Graph 1. Matting efficiency of 3 silica matting agents with equivalent particle size, but different pore volume

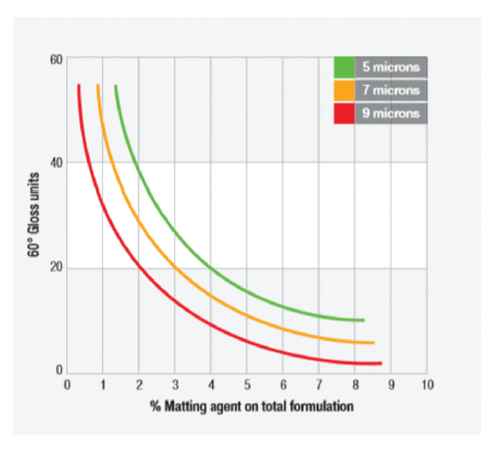

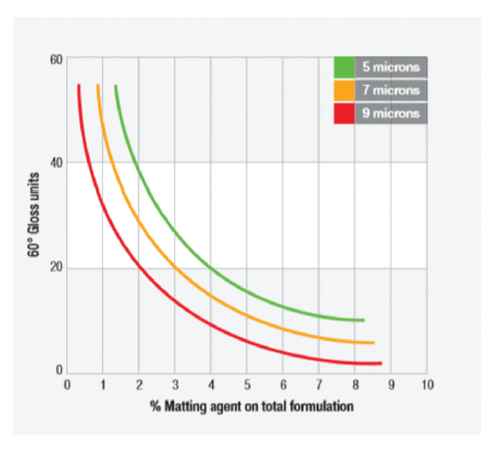

This time in Graphic 2, you’ll see 3 different matting agents with same pore volume bur different particle sizes. The larger the average particle size, the higher the matting efficiency.

Optimum matting efficiency with acceptable paint film properties can only be achieved by selecting the SYLOID® matting agent with an appropriate particle size in relation to the dry thickness of the coatings film.

Graphic 2. Matting efficiency of 3 silica matting agents with equivalent pore volume, but different average particle size

Graphic 2. Matting efficiency of 3 silica matting agents with equivalent pore volume, but different average particle size

Some SYLOID® silica products are surface treated with carefully selected organic compounds (e.g. waxes). The wax treatment prevents settling, in particular the formation of hard sediments, especially in low viscous, clear lacquers.

Wax treated products can also contribute positively to improving other surface properties, such as mar and scratch resistance. Wax treated products can exhibit a lower matting efficiency than untreated products with similar particle size. Besides the silica matting agent, other formulation and application properties infuence the final gloss.

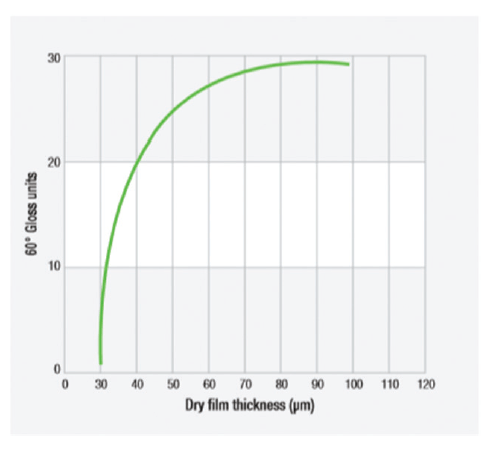

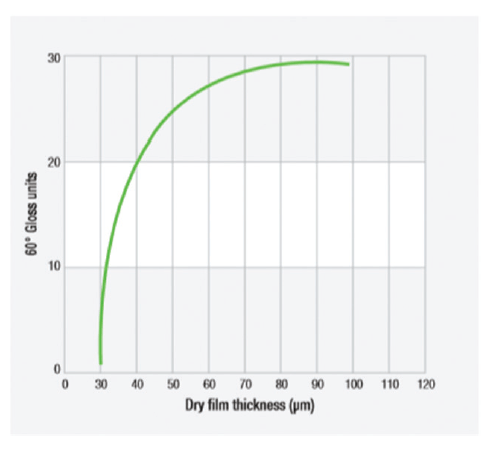

Graphic 3. Matting effificiency of treated and untreated silica matting agents with equivalent pore volume and particle size The higher the film weight at a given addition level of a selected matting agent product, the lower the matting effect. T

o matt thick films effectively, the selection of the largest acceptable particle size product is recommended.

Graphic 4. Influence of film thickness on gloss

Graphic 4. Influence of film thickness on gloss

As the required addition level of matting agents to achieve a defined gloss depends on the amount and the dynamics of film shrinkage that occurs during drying, the matting efficiency of SYLOID® matting agents can also be influenced by:

• The resin system (different curing mechanisms),

• The solids content (or the amount of volatile compounds such as solvents),

• The type of solvent (differing vapor pressure),

• The drying method (fast or slow drying).

Graphic 5. Matting efficiency of a given silica matting agent in different clear lacquer systems

To determine the most effective matting agent for your system, you may take a look at GRACE- SYLOID® product brochures online and contact directly Nordmann Turkey as their local distributer.

Graph 1. Matting efficiency of 3 silica matting agents with equivalent particle size, but different pore volume

This time in Graphic 2, you’ll see 3 different matting agents with same pore volume bur different particle sizes. The larger the average particle size, the higher the matting efficiency.

Optimum matting efficiency with acceptable paint film properties can only be achieved by selecting the SYLOID® matting agent with an appropriate particle size in relation to the dry thickness of the coatings film.

Graph 1. Matting efficiency of 3 silica matting agents with equivalent particle size, but different pore volume

This time in Graphic 2, you’ll see 3 different matting agents with same pore volume bur different particle sizes. The larger the average particle size, the higher the matting efficiency.

Optimum matting efficiency with acceptable paint film properties can only be achieved by selecting the SYLOID® matting agent with an appropriate particle size in relation to the dry thickness of the coatings film.

Graphic 2. Matting efficiency of 3 silica matting agents with equivalent pore volume, but different average particle size

Graphic 2. Matting efficiency of 3 silica matting agents with equivalent pore volume, but different average particle size Graphic 3. Matting effificiency of treated and untreated silica matting agents with equivalent pore volume and particle size The higher the film weight at a given addition level of a selected matting agent product, the lower the matting effect. T

Graphic 3. Matting effificiency of treated and untreated silica matting agents with equivalent pore volume and particle size The higher the film weight at a given addition level of a selected matting agent product, the lower the matting effect. T

Graphic 4. Influence of film thickness on gloss

Graphic 4. Influence of film thickness on gloss Graphic 5. Matting efficiency of a given silica matting agent in different clear lacquer systems

To determine the most effective matting agent for your system, you may take a look at GRACE- SYLOID® product brochures online and contact directly Nordmann Turkey as their local distributer.

Graphic 5. Matting efficiency of a given silica matting agent in different clear lacquer systems

To determine the most effective matting agent for your system, you may take a look at GRACE- SYLOID® product brochures online and contact directly Nordmann Turkey as their local distributer.