Edited By

Parkim Chemicals

Introduction

Celocell and Mastercell products are water soluble, nonionic cellulose ethers that are used in many industrial applications as water retention aids, thickening agents, protective colloids, suspending agents, binders and stabilizers. In this article, the main characteristics of Celocell and Mastercell have been compiled. In addition to the main characteristics of both product range, performance and importance of cellulosic rheology modifiers (mixed ethers – from the perspective of using MHEC) for modern architectural paints has been revealed.

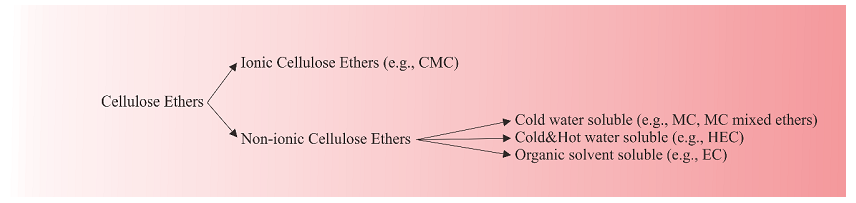

Industrial cellulose ethers are alkyl, alkylhydroxyalkyl, hydroxyalkyl ethers derived from cellulose. The main cellulose content comes from cotton linters (with 2,000-2,400 DP) and wood pulp (with 600-1,700 DP) and ethers are formed by substituting some of the cellulose hydroxyl groups. The use of one etherification agent in the substitution process results in a simple cellulose ether, whereas using different kinds of agents leads to mixed ethers.

Manufacture of Celocell & Mastercell cellulose ethers

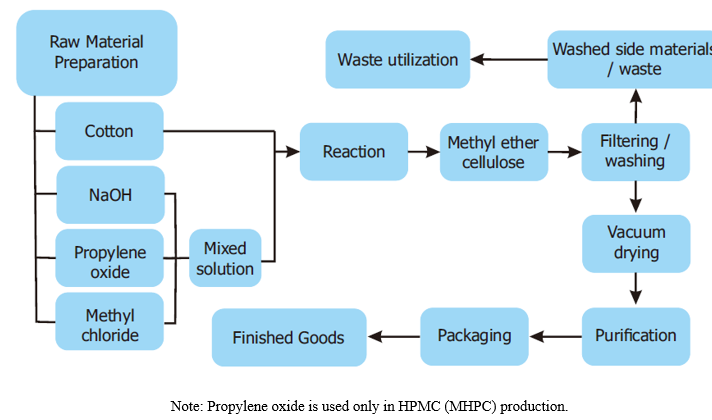

The manufacturing process is carried out in either one of several steps. The reactions taking place are alkalization and alkylation. These reactions can be carried out in the presence of solvents. (not must)

Pure cellulose has large crystalline regions due to hydrogen-bonded hydroxyl groups and is thus insoluble in water and in most organic solvents. In the first step of cellulose ether manufacturing, cellulose is activated with sodium hydroxide (NaOH) to become alkali cellulose.

The maximum solution viscosity of the final cellulose ether that can be obtained can only correspond to the DP of the original cellulose. By the selection of the substituent, the type of Celocell & Mastercell is determined. Mixed ethers can be produced with a mixture of reactants or by stepwise addition of the substituents. This reaction step is carried out under pressure and at increased temperature. The number of substituted hydroxyl groups per anhydro-glucose unit is expressed as DS, degree of substitution. The DS can vary between 0 and 3. As with all polymer reactions, this reaction does not occur uniformly along the polymer chain. The degree of substitution is therefore determined as a mean over the whole polymer chain and expressed as average degree of substitution (DS).

With alkoxylation, side chains are generated, which are themselves reactive. In this case, the molar ratio of alkoxy groups in the side chains to cellulose is specified and expressed as the average molar substitution (MS).

Purification of Celocell & Mastercell cellulose ethers

Celocell and Mastercell crude products are generally purified by washing with hot water. The they are dried, ground and screened to the desired particle size.

Surface treatment of Celocell & Mastercell cellulose ethers

It is necessary to delay hydration of the cellulose ethers in some applications. This property is achieved by reversible crosslinking with glyoxal. These grades (Celocell PM-DS types) show a reduced tendency to hydrate in the acid pH range. However, at higher pH values, the crosslinking reaction is reversed and the Celocell xx-DS type of cellulose ethers dissolve instantaneously.

Properties

Celocell and Mastercell cellulose ethers have a neutral taste and odor and are white to off-white in color.

Hygroscopy, cellulose ethers absorb water if stored under humid conditions. Celocell and Mastercell products are shipped in moisture proof bags, which protect them from moisture pickup.

Temperature stability, although Celocell and Mastercell products are organic compounds, they exhibit excellent temperature stability. Darkening of color or slow softening only occur at temperatures above 1400C. Decomposition occurs at temperatures above 2200C.

Solubility, all Celocell and Mastercell cellulose ethers are soluble in water in a colloidal state. The solubility depends on the cellulose ether concentration, the temperature of the solution, and the presence of other components such as salts or organic solvents. A few Celocell types are soluble in polar solvent mixtures. Typical examples are mixtures of methanol and methylene chloride.

Functions

Celocell and Mastercell cellulose ethers have a great number of valuable properties that find application in numerous industrial areas.

Water retention, high viscosity grades of Celocell and Mastercell exhibit excellent water retention property. Especially in construction industry, the addition of Celocell and Mastercell cellulose ethers reduces the tendency of water to seep away from gypsum or cement containing formulations into porous substrates. This ability reduces burning and thus improves workability. Celocell cellulose ethers have a similar effect in water based paints and varnishes and in emulsion plaster. The higher concentration and the higher solution viscosity, the higher water retention. When very fast development of the water retention property is required, for example in sprayable plaster, Celocell and Mastercell grades with a very fine particle size and large particle surface area is used.

Thickening and stabilization action, the viscosity of various aqueous-organic and organic solutions, slurries, and dispersions can be adjusted to the desired level by adding only a small amount of Celocell and Mastercell polymer. The desired consistency is controlled either through the molecular weight of Celocell and Mastercell or by their concentration.

Binding ability, due to their polymeric structure, Celocell and Mastercell cellulose ethers have good binding ability, for example in white-wash for pigments and fillers. These products control rheology and consistency of water-based paints, and stabilizes pigments and fillers.

Film formation, films with high transparency and tensile strength can be prepared from Celocell and Mastercell solutions. These films are soluble in water and resistant to most organic solvents, fats and oils. Insolubility in water can be obtained with these films by crosslinking with glyoxal, melamine formaldehyde resins or with other multifunctional compounds. An example of the use of the film-forming ability of Celocell and Mastercell is synthetic tobacco sheet.

Adhesion, because of their high adhesive strength, solutions of Celocell and Mastercell are used as wallpaper adhesives and as adhesives in cigarette and cigar manufacturing. Special types of Celocell and Mastercell grades are used in modern building materials. They increase the adhesive strength of stuccos, mortars and emulsion based adhesives.

Application Fields

Construction industry, Celocell and Mastercell products improve water retention, adhesion and processability of plaster. Mechanically applied plasters based on gypsum or lime-gypsum; of other hydraulically setting compounds such as mortars, spackling compounds, tile cement and adhesives, and of plaster mortar binders based on cement. These cellulose ethers are also used as plasticizers, adhesive agents, and viscosity controllers in gypsum plaster, joint compounds, adhesives and mortars; and serve as stabilizers and thickeners in decorative nonhydraulic stuccos.

Detergents and cleaners, especially low viscosity Celocell grades incrase the ability of laundry detergents to suspend dirt particles, inhibit greying, and promote color fastness in fabrics.

Ceramics, cellulose ethers are used as plasticizer and green-strength agents in modern, nonplastic compositions for advanced ceramics.

Coating industry, in water based paints, Celocell and Mastercell products are used to control consistency and flow characteristics, and to stabilize pigments and fillers.

For modern architectural paints, cellulose ethers are used as multifunctional rheological additives and they play a significant role in determining the flow behaviour, pigment suspension and water retention of dispersion paints.

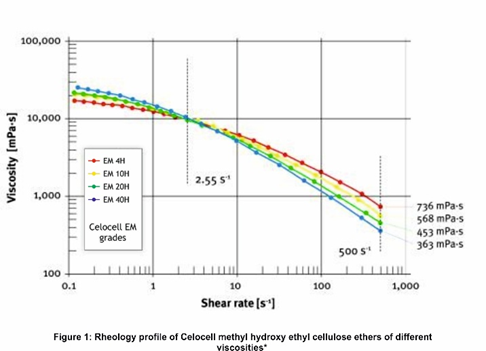

Low viscosity methyl hydroxyethyl cellulose ethers (MHEC) have further expanded the performance spectrum of paints. On account of heir versatile properties, cellulose ethers are used as paint additive worldwide, not only for improving rheology, but also for acting as a suspension and water retention agent. Spatter resistance, open time, flow, hiding power and storage stability are largely a function of the cellulose ether used. Like all cellulose ethers, methyl celluloses are characterized by a rheological profile that is strongly pseudoplastic, i.e. the viscosity of an aqueous solution decreases rapidly with increasing shear rate. This is a prerequisite for stabilizing the pigment in the paint without sedimentation while simultaneously achieving good flow behavior and easy application. Especially with modern one-coat paints, however, it is desirable to limit the loss of brushing viscosity at very high shear rates. This prevents the paint roller from sliding to ensure that a thick wet film can be applied to the substrate.

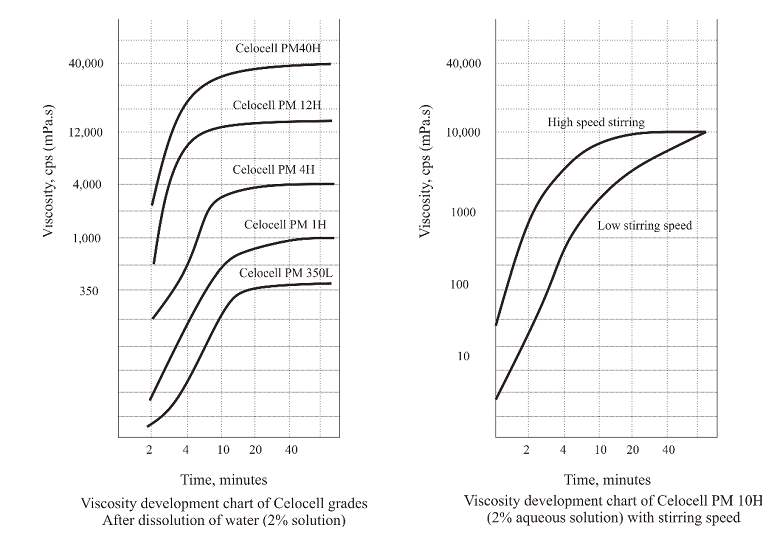

The other determining factor besides structure for the degree of brushing viscosity is the viscosity grade of the cellulose ether. (see as in the below figure)

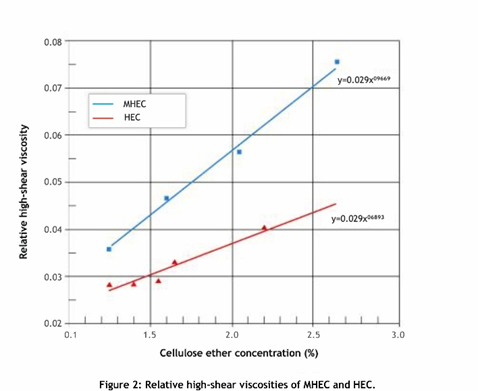

Low viscosity Celocell methyl cellulose ethers (e.g., Celocell MHEC) yield wet film thicknesses in paints that cannot be achieved with classic cellulose monoethers (e.g., Celocell HEC). Increasingly stringent requirements with respect to the yield and hiding power of modern one-coat paints can often be satisfied simply by using these mixed cellulose ethers. (see as in the below figure)

If it is required or desired, brushing viscosity can be further increased or adjusted by also using associative polyurethane thickeners. Depending on the cellulose ether-polyurethane combination chosen, the overall flow behaviour can be specifically optimized with respect to the other quality criteria (storage stability, open time, tintability, etc.).

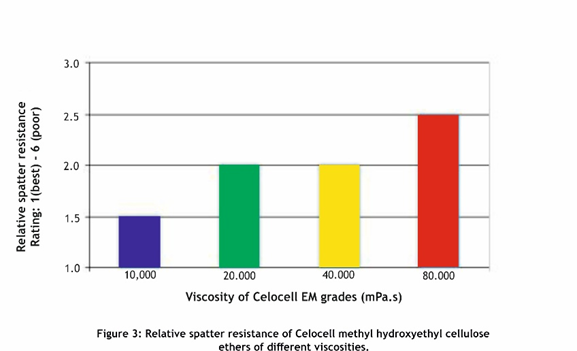

For minimized spatter, when applying paint with a roller, elongation stresses in the tear-away zone of the paint film cause spattering. The chain length of the methyl cellulose has a decisive influence on the magnitude of these stresses. Spatter can be sharply minimized by the use of low-viscosity methyl celluloses. This effect is largely independent of the type of binder or pigment used and can thus be used to not only satisfy the requirements of today’s high-grade paints, but also to easily adjust formulations in the future. With open time, hiding power, spatter resistance and storage stability, low-viscosity methyl hydroxyethyl celluloses very economically optimize four essential properties of high-grade paints.

With a full range of cellulose ethers (HEC, MHEC, HPMC) and all viscosity level options, we are ready to deliver “durable and permanent beauty” to your formulation.