This concept, which has been on the agenda of the world for a long time, is on the agenda especially with the marketing (demand creation) promotions and presentations of some internationally known companies producing technology.

However, for some reason, industry 4.0 (digital transformation in industry) does not contain many healthy and rational clues as to how to implement the application.

In my the full text, I deemed it necessary to present what should be done especially during the transition process and to present this process to the attention of you, respected readers, followers and sector players.

Some Basics (Future Value Added)

• In 2019, the number of robots to be used in the industry will be approximately 3 million. The number of interconnected devices increases from 13 billion to 29 billion.

• In 2020, the Internet of Things market size will increase from USD 656 Billion to USD 1.7 Trillion.

• The economic impact of industrial robots is $ 0.6- 1.2 Trillion a year.

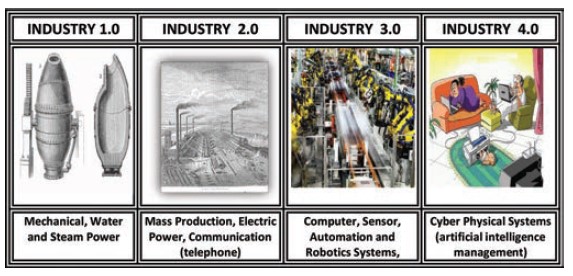

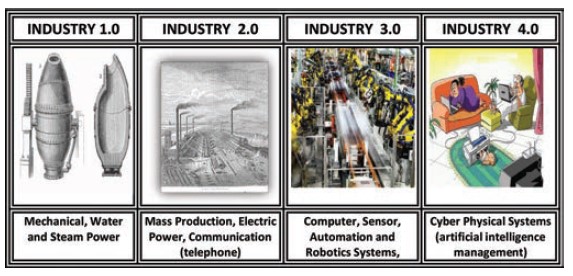

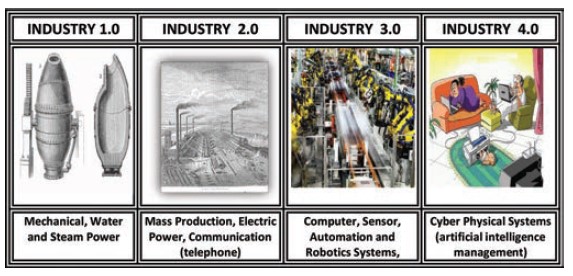

Industrial Stages in the World

Why Industry 4.0?

In our diagram above, we tried to explain the real reasons of digital transformation in industry. As you know, we call the science of meeting unlimited human needs with scarce resources in the world economy.

Should We Invest Technologically?

The answer to our question will naturally be no. What kind of a process should the company management make the decision to skip the level of digital transformation?

In the next part of our article, we have described how to manage this process in general according to our experience and knowledge. We hope it will be useful to the parties.

Industrial Transformation Project Process

• Meeting with the top management:

The meeting of the chairman of the board of directors or members of the board of directors or CEO and/or General Manager, Directors and all directorates in the organization chart is organized. It is decided on which periods the meeting will be held in the following processes.

Explain the purpose of peak management. Estimated project duration is determined by taking opinions about project duration and expectations.

• Determination of current and potential customer expectations:

Data are collected and finalized on topics such as customer feedback, past experiences, and future expectations of customers. In addition, the reasons why potential customers do not buy the product from us are determined and expectations are reported.

• Preparation of the family constitution for business continuity (institutionalism) (indispensable for continuity):

Based on the existing management structure, an effective family management constitution is prepared and discussed in order to ensure continuity in management by discussing with the family members the necessary work for the systematic and respectful management of how and under what conditions the management can be unfairly and unjustly towards future generations.

• Current situation analysis of production processes, determination of current production capacity utilization rates:

Processes are determined based on facts by determining the processes currently applied in production. Capacity utilization rate does not generally occur as 100 percent.

There may be various disruptions during production, power cuts, machine failures, machine and installation maintenance breaks, holidays, strikes, disruptions in working hours, seasonal reasons, such as problems in the use of capacity occurs. The most important of these is that sales are not realized at the expected levels.

In order to measure capacity utilization in production, machine stops and take-offs are generally calculated. Because the manufacturing industry is generally the most predominant sub-sector of the industrial sector.

In this case, the total machine capacities of the selected plant and the actual capacity ratios used are handled. In this study, commercial data are evaluated. (For example, average profitability level.)

• Determination of current technology and measuring its level in the industrial process:

The technological level of the machinery used in the existing processes is determined and its location in the current industrial process is reported and determined by analysis.

• Determining the required level of industry transformation (optimum change) as a result of customer and market studies:

Customer and market expectation reports are examined, first of all it is necessary to prepare the roadmap by making cost-benefit analysis in order to maximize the capacity utilization rate of the existing technology. This map consists of two methods.

These; a) Determination of technological systems for the production required and application planning. b) Determining what the technological level will be and how it will be for the required machine park.

• The current financial structure of the enterprise and industrial transformation budgeting (optimization):

The balance of payments, financial leverage ratio, investment capacity and capability of the enterprise should be determined by time diagram.

Financial (costof- money) coverage of the required budget for the required technological transformation with short (1-3 years), medium (3-5 years), long (5-10 years) plans, an estimate of what value-added can be; the technology to be procured must have already proven itself.

• Review:

All studies, plans and strategies should be reviewed and revised according to the constantly changing customer expectations and\or postponed and \ or stopped decisions should be evaluated and realistic rational improvements should be provided.

Simulation process for each study should be carried out and continued until optimization is achieved.

Halil İ. Kırmacı

Master of Business Administration

Industrial Engineer

Management Consultant

Kırmacı Mühendislik Danışmanlık Tic.

Halil İ. Kırmacı

Master of Business Administration

Industrial Engineer

Management Consultant

Kırmacı Mühendislik Danışmanlık Tic.

In our diagram above, we tried to explain the real reasons of digital transformation in industry. As you know, we call the science of meeting unlimited human needs with scarce resources in the world economy.

In our diagram above, we tried to explain the real reasons of digital transformation in industry. As you know, we call the science of meeting unlimited human needs with scarce resources in the world economy.

Halil İ. Kırmacı

Master of Business Administration

Industrial Engineer

Management Consultant

Kırmacı Mühendislik Danışmanlık Tic.

Halil İ. Kırmacı

Master of Business Administration

Industrial Engineer

Management Consultant

Kırmacı Mühendislik Danışmanlık Tic.