Densipol WO 3025 is a high-quality defoamer that can be added directly to water-based systems and can be used in a wide pH range with other agents and binders.

It creates a long-lasting effect, and it is a stable product. WO 3025 is a hydro-carbon based defoamer, containing oil-based hydrophobic compounds. It is mineral oil based.

This high-performance, new-generation defoamer, formulated with mineral oils, quickly and permanently removes any foam that has formed, as well as preventing foam formation from the very beginning of the process.

Densipol WO 3025 offers the most ideal solution in terms of quality in terms of price-quality, providing excellent stability and emulsification.

Densipol WO 3025 is a high-quality defoamer that can be added directly to water-based systems and can be used in a wide pH range with other agents and binders.

It creates a long-lasting effect, and it is a stable product. WO 3025 is a hydro-carbon based defoamer, containing oil-based hydrophobic compounds. It is mineral oil based.

This high-performance, new-generation defoamer, formulated with mineral oils, quickly and permanently removes any foam that has formed, as well as preventing foam formation from the very beginning of the process.

Densipol WO 3025 offers the most ideal solution in terms of quality in terms of price-quality, providing excellent stability and emulsification.

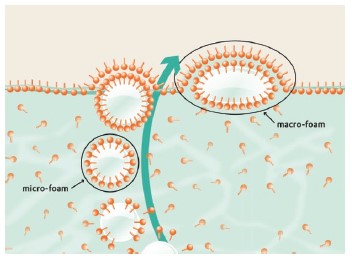

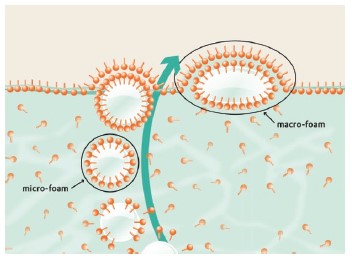

Figure 2. The defoamer effect of hydrophobic particles in the formulation.

Densipol WO 3025 provides the highest quality foam control during production. It has perfect compatibility with different types of binders such as acrylic, acrylic, alkyd (water based), styrene butadiene and polyvinyl acetate. It is generally suggested that its 2/3 is used at the beginning of the process, and the rest is used before the binder usage. The Densipol WO series is a highly successful and favored defoamer with a fast, effective and permanent and anti-foaming performance, high pH strengths and high heat stability, excellent chemical stability, compatibility with other chemicals and low cost. Alper Bağcık

Technical Sales Manager

Asil Kimya ve Boya San. Tic. A.Ş.

Alper Bağcık

Technical Sales Manager

Asil Kimya ve Boya San. Tic. A.Ş.