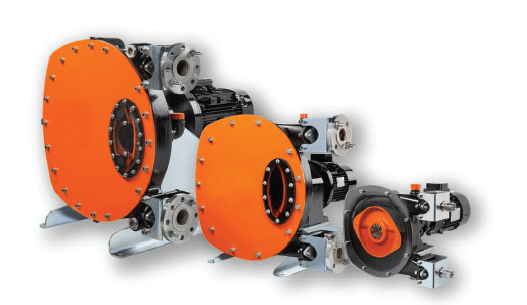

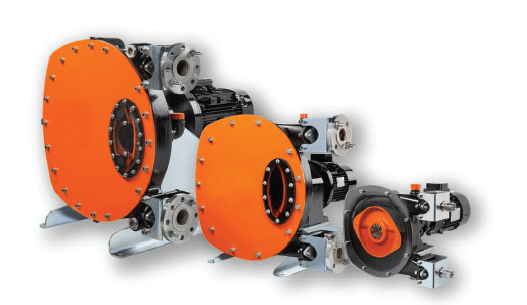

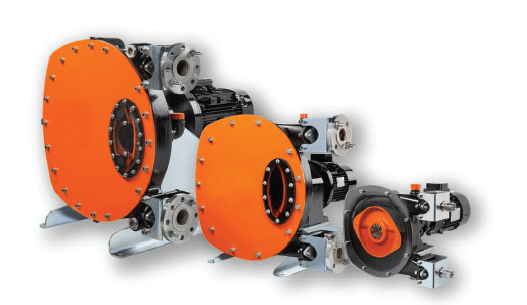

With more than 20 years of experience pumping and transferring difficult chemicals and fluids, the ABAQUE Peristaltic Hose pump will handle your toughest pumping needs — from abrasive and aggressive to shearsensitive and viscous fluids.

ABAQUE pumps currently operate in some of the most demanding environments including mining, water and wastewater treatment, energy, chemical processing and OEM applications.

Seals-free ABAQUE Peristaltic Hose Pumps is the solution for abrasive products containing suspended particles up to 77 m3/h at a max. 16 bars pressure.

Performance

• Seal-free design eliminates leaks and contamination.

• Excellent Self-priming 25,5ft (9 meters).

• Ability to run dry continuously.

• Can handle your toughest pumping needs from abrasive and aggressive fluids to sheer sensitive and viscous materials.

• The pump is capable of running in forward or reverse.

• It is solid construction and advanced design also reduce maintenance and repairs.,

Options

• Hose: Natural rubber, Buna (NBR), EPDM, NR FDA

1935/2004, NBR FDA, Hypalon.

• Leak detector.

• Vacuum Kit.

• Nonmetallic insert (PPH, PVDF).

Features & Benefits

• Self-priming

• Can run in forward or reverse

• Suction-lift capabilities to 32.8 feet (9.5 meters)

• Discharge pressures to 232 psi (16 bar)

• Handles water-like viscosities as high as 352,000 SSU (70,000 cSt)

• Transfers solid and soft particles.

• All hoses handle liquid temperature from 32°F (0°C) to 176°F (80°C).

• EPDM hoses handle temperature up to 194°F (90°C).

Markets

• Industrial Wastewater Treatment.

• Municipal Water Treatment.

• Mines/Quarries.

• Chemical industry.

• Sanitary industry.

The Peristaltic Principle

• High Performance: Seal-less design eliminates leaks and product contamination, and have the ability to run dry continuously without adversely affecting the pump’s performance, pressure, and accuracy (no slip).

• Reliability: The Abaque pump has none of the usual parts that create problems on other pumps: Seats, valves, mechanical seals. The hose is the only replacement part. • Handling of the Toughest Pumping Challenges: including extremely abrasive and aggressive fluids, solid loaded liquids, as well as shear sensitive and viscous materials.

Ersin Genç

Ersin Genç

Industrial Sales Chief

Leontek Dış Ticaret Ltd. Şti

Ersin Genç

Industrial Sales Chief

Leontek Dış Ticaret Ltd. Şti

Ersin Genç

Industrial Sales Chief

Leontek Dış Ticaret Ltd. Şti