Poliaspartic polyurea was first introduced in the 1990s, and its’ usage has been increasing day by day [1]. In recent years, many scientific articles have been published on the development of the mechanical and physical properties of new types of polyaspartics [2] [3].

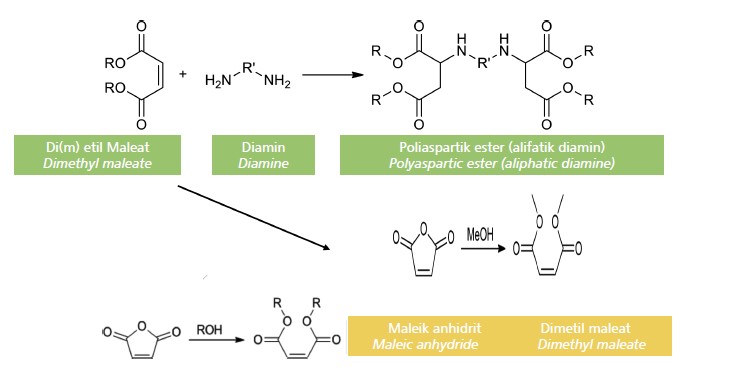

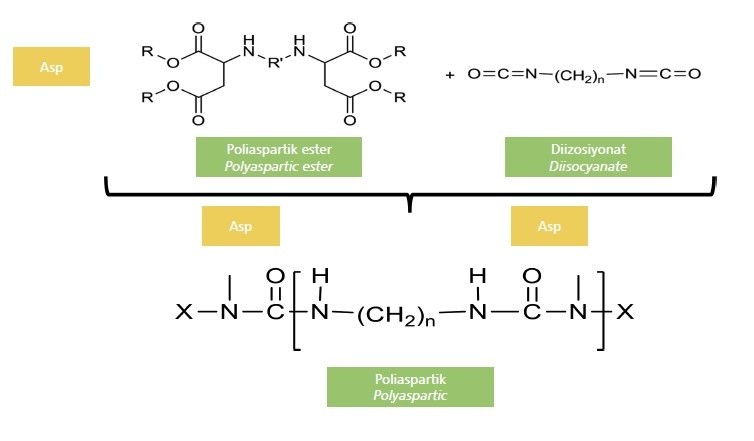

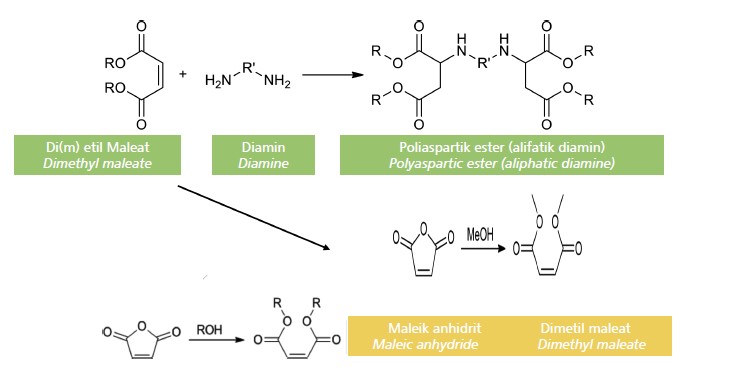

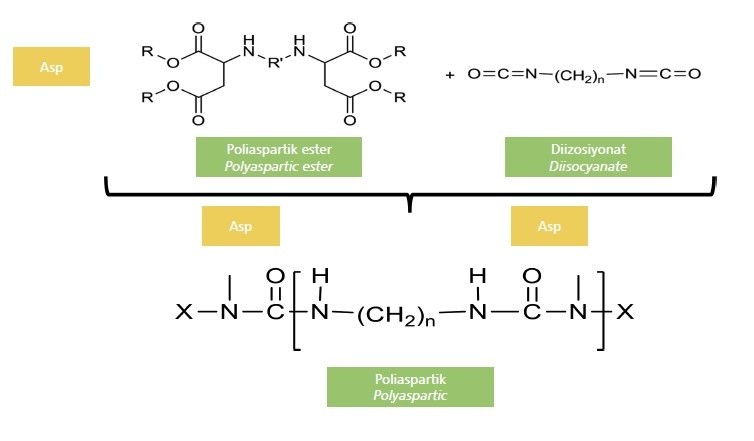

Polyaspartic coatings are based on the reaction of a polyisocyanate with a polyaspartic ester which is an aliphatic diamine. Polyaspartic polyurea; is a new generation aliphatic polyurea floor coating system which allows two-component, UV resistant and colorfastness to be desired.

Figure 1. Synthesis of polyaspartic ester.

Figure 2. Polyaspartic 2K polyurea synthesis [4].

Polyaspartic resins are more preferable resins because they are high in mechanical and chemical (adhesion, chemical solvents, acids and bases, hardness and mechanical strength) properties compared to double component resins such as epoxy and acrylate. General usage areas are given below.

Application Areas of Polyaspartic Resin

•Color stability in exterior coating required,

•Swimming pools and furniture,

•Roofs and garages,

•Wind power plants,

•Outdoor and indoor pipe coatings,

•Entertainment parks and playground,

•In plane hangars,

•On the floors of shopping malls, hospitals and airports.

Figure 3. Application areas of polyaspartics.

Polyaspartic resins are preferred although they are expensive with many advantageous properties listed below.

Advantages

• Depending on the product -34°C and 60°C can be applied at low temperatures. They can be used safely in hot and cold climates without deteriorating,

• When hardened, they can tolerate high temperature up to 245°C,

• Polyurethanes have more wear and impact resistance than epoxy or urethane coatings,

• Does not make redness or bleaching,

• It is mechanically and chemically resistant 4 times more than its strongest competitor in the market,

• Drying time will be shorter and will not seen yellowing effect and can be used in a short time. High humidity does not restrict applications, but some products are set faster in high humidity,

• They do not stain, resist oil and oil penetration and the concrete is protected from light acids,

• Polyurethanes have excellent penetration properties, which means that they form excellent bonds with the concrete,

• Better decorative use,

• Its elasticity and UV resistance are higher,

• Higher resistance to wear.

In view of the technical characteristics of polyaspartic resins, IZASP1 and IZASP2 were developed by R&D department of our company with three functional groups, which were cured in the desired time interval.

Figure 4. Application of IZASP1 and IZASP2 to gravel stones.

IZASP1 and IZASP2 are aliphatic floor coating resins with high cross-bonding ratio, solvent free, high chemical resistance, bright, UV resistance and high temperatures that can tolerate. Our R&D activities are continuing intensively.

Summary

Polyaspartic coatings, epoxy and polyurethane coatings, such as widely used as preferred coatings, exhibit high durability and hardness properties.

IZASP1 and IZASP2 products of our company have been compared with some of the products available in the market and gained features such as the desired drying time, larger film thickness, long pot life, odorless, low color values and high compatibility with most surfaces.

Our IZASP1 and IZASP2 products also provide protection against corrosion that makes it suitable for harsh environmental applications.

Dr. Cemil Dizman

Ph.D -R&D Manager

İzel Kimya

Dr. Cemil Dizman

Ph.D -R&D Manager

İzel Kimya

Semiha Eral

B.S.-R&D Researcher

İzel Kimya

Semiha Eral

B.S.-R&D Researcher

İzel Kimya

References

[1] By Carl Angeloff, P.E., Edward P. Squiller, Ph.D., and Kurt E. Best, Two-component aliphatic polyurea coatings for high productivity applications, 2002.

[2] Jaime V., Maria A., pH-responsive poly (aspartic acid) hydrogel-coated magnetite nanoparticles for biomedical applications, 2017.

[3] Fang L.,Zhao Y., Preparation and Water Absorbent Behavior of Superabsorbent Polyaspartic Acid Resin, 2006.

[4] Dudley J., Polyurea Elastomer Technology: History, Chemistry & Basic Formulating Techniques, 2004.

Dr. Cemil Dizman

Ph.D -R&D Manager

İzel Kimya

Dr. Cemil Dizman

Ph.D -R&D Manager

İzel Kimya

Semiha Eral

B.S.-R&D Researcher

İzel Kimya

Semiha Eral

B.S.-R&D Researcher

İzel Kimya