Abstract

Glass Fiber Reinforced composite materials has become the material of choice in many different sectors due to their low production costs, high specific mechanical properties, ease of design and shaping, and many more reasons.

Especially its use in aviation, military and space fields is increasing day by day. Accordingly, it has emerged as a material that attracted a lot of attention and directed successful works, especially in the automotive industry.

Glass Fiber Reinforced composite materials constitute approximately 90% of our product range. Within the scope of the importance we attach to innovative and sustainable works as a company, a new product study has been completed in order to add a new R&D study to our product range and to give a new perspective to the entertainment industry. The Mountain Coaster

(Trail Coaster) recreational cars, whose outer shell is made using FRP composite material and whose design and engineering works are created in our own R&D structure, are designed.

Our car, which we realize as 100% domestic production, has succeeded to be among the preferred products by adding a different perspective to the entertainment industry.

Composite Body Mountain Coaster Car

Polin Water Parks, established in Istanbul in 1976, is a world leader in the design, production and assembly of water slides and water parks. Polin, which has realized more than 3000 water park projects in 105 countries, has realized many firsts with its innovative, superior quality understanding and technology leadership.

Today, the biggest and award-winning water parks of many countries, even the continent, are signed by Polin. The King Cobra slide launched by Polin, which has the widest product range in the world, was selected as the best water slide in Europe in 2014 and 2015.

Polin has been using the RTM (Resin Transfer Molding) closed mold technology, which has significant advantages such as the production of space systems since 2006. Polin slides with two sides of bright surface and smooth, stronger and lighter, visibility and excellent product acquisition has become firsts at RTM technology.

This technology is the most advanced in slide production. Polin is the first and only European water slide producer to produce using this production technique.

All design, production, assembly and service processes of Polin water slides have been under ISO International Quality Management system since 2003; It is carried out in accordance with European (EN) and American (ASTM) Norms. Polin is the first European water slide producer to have this quality certificate.

Polin, which adds new ones to the award-winning water slides and water park projects day by day, attaches great importance to new product works.

Our R&D studies are continuing rapidly in order to give innovative perspectives to the entertainment industry, to design new products and to make the designed products productive and projectable.

Figure 1

Figure 1. Our award-winning water slide

Figure 2. Our sample projects

With the introduction of composite materials to the Turkish Automotive Industry for the first time in the vehicle body of Anadol brand in the 1960s, and its rapid expansion in the following years, the use composites at interior and exterior equipment in vehicles of many different concepts has rapidly become widespread.

Many applications have been carried out with the easy hand lay-up method. In the recent processes, production methods and techniques were developed, and mass production was started, and composite materials were started to be used in much wider areas.

In this context, with our design and engineering structure, our Mountain Coaster (Trail Coaster) product, which we have been working and developed within our own R&D structure, which has been proven to be inventive with 100% domestic production, an example multidisciplinary systems which is used together in the automotive, entertainment and composite sectors is an important product.

Such as low density, high strength, rigidity and high production speed of Glass Fiber Reinforced composite material was preferred as a design in Mountain Coaster cars due to its many features.

Mountain coaster is a system of adrenaline production by two-person coasters that move over rails which are installed on a slope. In a natural environment, factors of excitement and safety are maximized in design of the system that allows a downhill speed up to 40km/h by gravity only.

Figure 3.

Figure 3. Mountain coaster model

Rails may be designed in a length that varies between 700m and 4000m according to the span and inclination of the area. Average land slope must be minimum 7% (4°). Rails must be installed on supports in accordance with the topography of the land. Land may be levelled if necessary.

Radii of the curves must comply with the standards and desired speed, and they may vary between 4m and 9m. Slope angle must be calculated accordingly to keep driving performance at the top level.

Peaks and pits in the rail design allow different driving experiences. Trees and natural structures are preserved in design. Tunnels and bridges may be designed if necessary.

Figure 4. Mountain train road model

Ergonomically designed sleds can be used by 1 or 2 persons. The sleds are designed in a manner to allow children between ages 3 and 8 to drive together with an adult and children older than 8 to drive on their own.

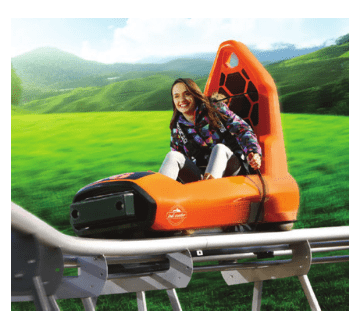

Figure 5. Mountain train user view

Thanks to the braking system, users may safely drive the sleds at the desired speed. When the braking system is not touched, the sleds automatically shift to automatic braking mode and they can only be speeded up intentionally. The sleds are equipped with safety belts. Safety belts cannot be released when the sleds are in motion.

Automatic clutches prevent exceeding of the standard maximum speed, which is defined as 40 km/h. The sleds, which are finished with energy absorbing elegant bumpers, can ordered in any color.

Mountain coaster consists of rails, sleds, climbing conveyor, signalization system (automation) and a station building.

Climbing Conveyor and/or Sled Lift

This system carries hanging sleds to the upper level with or without drivers. It may be designed up to 40% (22°) slope. Climbing speed may be adjusted according to the desired capacity.

Automation System with Emergency Brake

This is the system that controls the cars moving on rails, provides car data to the operator and ensures that cars approach each other slowly in case users fail to apply the brakes.

Station Building

The station building, which is designed according to the size of the project, includes the platform used for getting on and off the sleds and the operator conveyor. In addition, it also has a storage area, sled lifter and a maintenance area.

Rail System

All wear and thermal deformations are taken into consideration in design of the rails, which are made of 316L stainless steel. In the entertainment tools industry, where user safety is the most important factor, engineering design of the rails is made to the finest details. Necessary precautions are taken to ensure environmental safety as well as user safety.

The automatic braking system which keeps the sleds on the rails at a distance is optional. The automatic braking system prevents sleds from approaching each other closer than 40m.

Figure 6. Mountain train user view

Thanks

We would like to thank our R&D Director Mr. Ali Cansun and Polin Waterparks for supporting this work.

Figure 1. Our award-winning water slide Figure 2. Our sample projects

With the introduction of composite materials to the Turkish Automotive Industry for the first time in the vehicle body of Anadol brand in the 1960s, and its rapid expansion in the following years, the use composites at interior and exterior equipment in vehicles of many different concepts has rapidly become widespread.

Many applications have been carried out with the easy hand lay-up method. In the recent processes, production methods and techniques were developed, and mass production was started, and composite materials were started to be used in much wider areas.

In this context, with our design and engineering structure, our Mountain Coaster (Trail Coaster) product, which we have been working and developed within our own R&D structure, which has been proven to be inventive with 100% domestic production, an example multidisciplinary systems which is used together in the automotive, entertainment and composite sectors is an important product.

Figure 1. Our award-winning water slide Figure 2. Our sample projects

With the introduction of composite materials to the Turkish Automotive Industry for the first time in the vehicle body of Anadol brand in the 1960s, and its rapid expansion in the following years, the use composites at interior and exterior equipment in vehicles of many different concepts has rapidly become widespread.

Many applications have been carried out with the easy hand lay-up method. In the recent processes, production methods and techniques were developed, and mass production was started, and composite materials were started to be used in much wider areas.

In this context, with our design and engineering structure, our Mountain Coaster (Trail Coaster) product, which we have been working and developed within our own R&D structure, which has been proven to be inventive with 100% domestic production, an example multidisciplinary systems which is used together in the automotive, entertainment and composite sectors is an important product.

Figure 3. Mountain coaster model

Rails may be designed in a length that varies between 700m and 4000m according to the span and inclination of the area. Average land slope must be minimum 7% (4°). Rails must be installed on supports in accordance with the topography of the land. Land may be levelled if necessary.

Figure 3. Mountain coaster model

Rails may be designed in a length that varies between 700m and 4000m according to the span and inclination of the area. Average land slope must be minimum 7% (4°). Rails must be installed on supports in accordance with the topography of the land. Land may be levelled if necessary.